A kind of preparation method and application of enzymolysis-oxidized starch moisturizing agent for tobacco

A humectant and oxidized starch technology for tobacco, which is applied in the field of cigarettes, can solve the problems of less raw material sources, high cost, and complicated preparation process, and achieve the effects of reducing tobacco leaf consumption, improving processing resistance, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

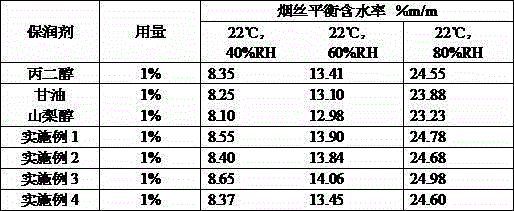

Image

Examples

Embodiment 1

[0020] Example 1 .Add 350g of potato starch into water to make 30% starch milk, adjust the pH of the system to about 6, then add 5.5mg of medium-temperature α-amylase (enzyme activity is 100,000U / g), react at 75°C for 100min, Enzyme inactivation is carried out, followed by cooling, dehydration, drying, crushing and sieving to obtain enzymatic starch. Add enzymatic starch to ethanol / water (V / V=70:30) solution to make 36% starch milk, then use 2% sodium hydroxide aqueous solution to adjust the pH value of starch milk to 8-10. Add 19g of sodium hypochlorite within 1-2 hours, and react at 50°C for 8 hours. In addition, during the reaction process, 2% aqueous sodium hydroxide solution should be added dropwise to stabilize the pH value at 8-10. After the reaction, use 10 % hydrochloric acid ethanol / water solution to neutralize to neutral, and reduce excess sodium hypochlorite with sodium sulfite, and finally dehydrate, wash, dry, pulverize and sieve to obtain enzymatic-oxidized sta...

Embodiment 2

[0021] Example 2 .Add 350g of potato starch into water to make 30% starch milk, adjust the pH of the system to about 6, then add 7mg of medium-temperature α-amylase (enzyme activity is 100,000U / g), react at 75°C for 150min, and carry out Enzyme inactivation, followed by cooling, dehydration, drying, crushing and sieving to obtain enzymatic starch. Add enzymatic starch to ethanol / water (V / V=70:30) solution to make 36% starch milk, then use 2% sodium hydroxide aqueous solution to adjust the pH value of starch milk to 8-10. Add 30g of sodium hypochlorite within 1-2 hours and react at 50°C for 8 hours. In addition, during the reaction process, 2% sodium hydroxide aqueous solution should be added dropwise to stabilize the pH value at 8-10. After the reaction, use 10 % hydrochloric acid ethanol / water solution to neutralize to neutral, and reduce excess sodium hypochlorite with sodium sulfite, and finally dehydrate, wash, dry, pulverize and sieve to obtain enzymatic-oxidized starch...

Embodiment 3

[0022] Example 3 .Add 350g of sorghum starch into water to make 30% starch milk, adjust the pH of the system to about 6, then add 40mg of high-temperature-resistant α-amylase (enzyme activity is 10000U / mL, react at 100°C for 120min, then carry out Inactivate the enzyme, and perform cooling, dehydration, drying, crushing and sieving in sequence to obtain the enzymatic starch.Add the enzymatic starch to the ethanol / water (V / V=75:25) solution to make 37% starch milk , and then use 2% sodium hydroxide aqueous solution to adjust the pH value of starch milk to 8-10, add 45g potassium permanganate within 1-2 hours, and react at 50°C for 10 hours. In addition, during the reaction process, it should be continuously Add 2% aqueous sodium hydroxide solution dropwise to stabilize the pH value at 8-10. After the reaction, neutralize to neutral with 10% ethanol / water solution of hydrochloric acid, and reduce excess potassium permanganate with sodium sulfite, and finally Carry out dehydrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com