Patents

Literature

49 results about "Amylomaize Starch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Easy open water soluble blister package

InactiveUS20060260973A1Easy to openEasy disposalSmall article dispensingFlexible coversWater solublePolymer composition

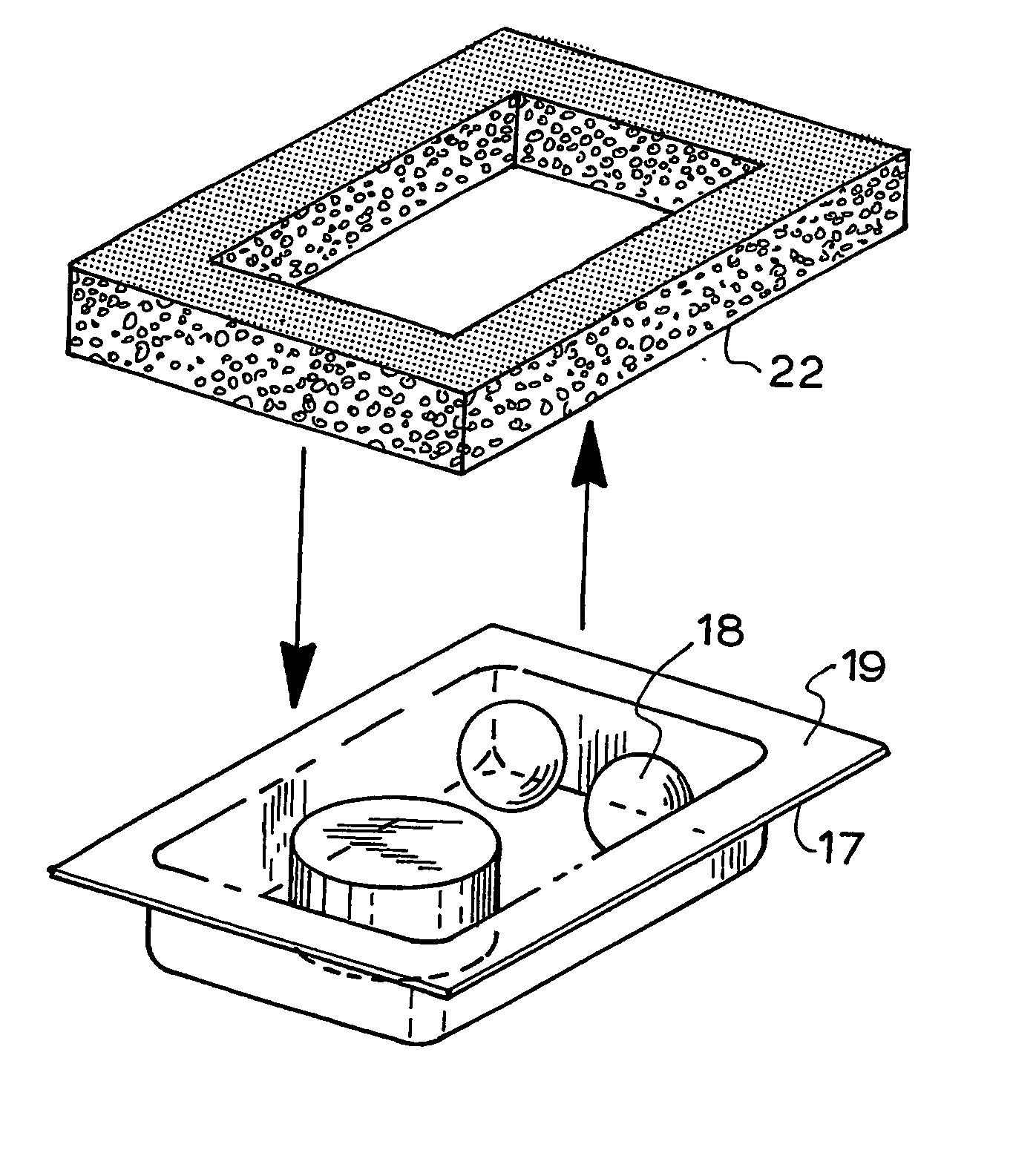

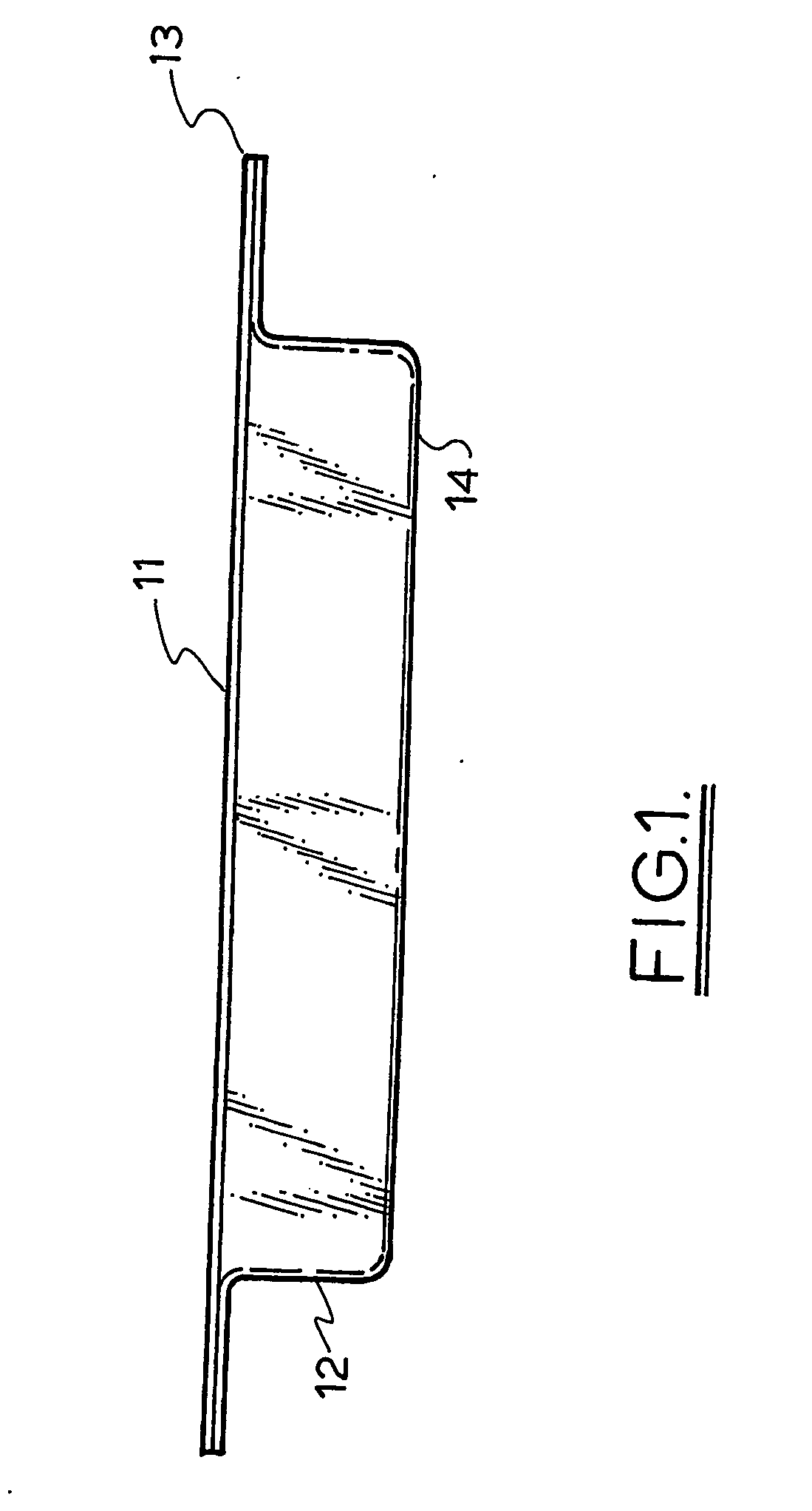

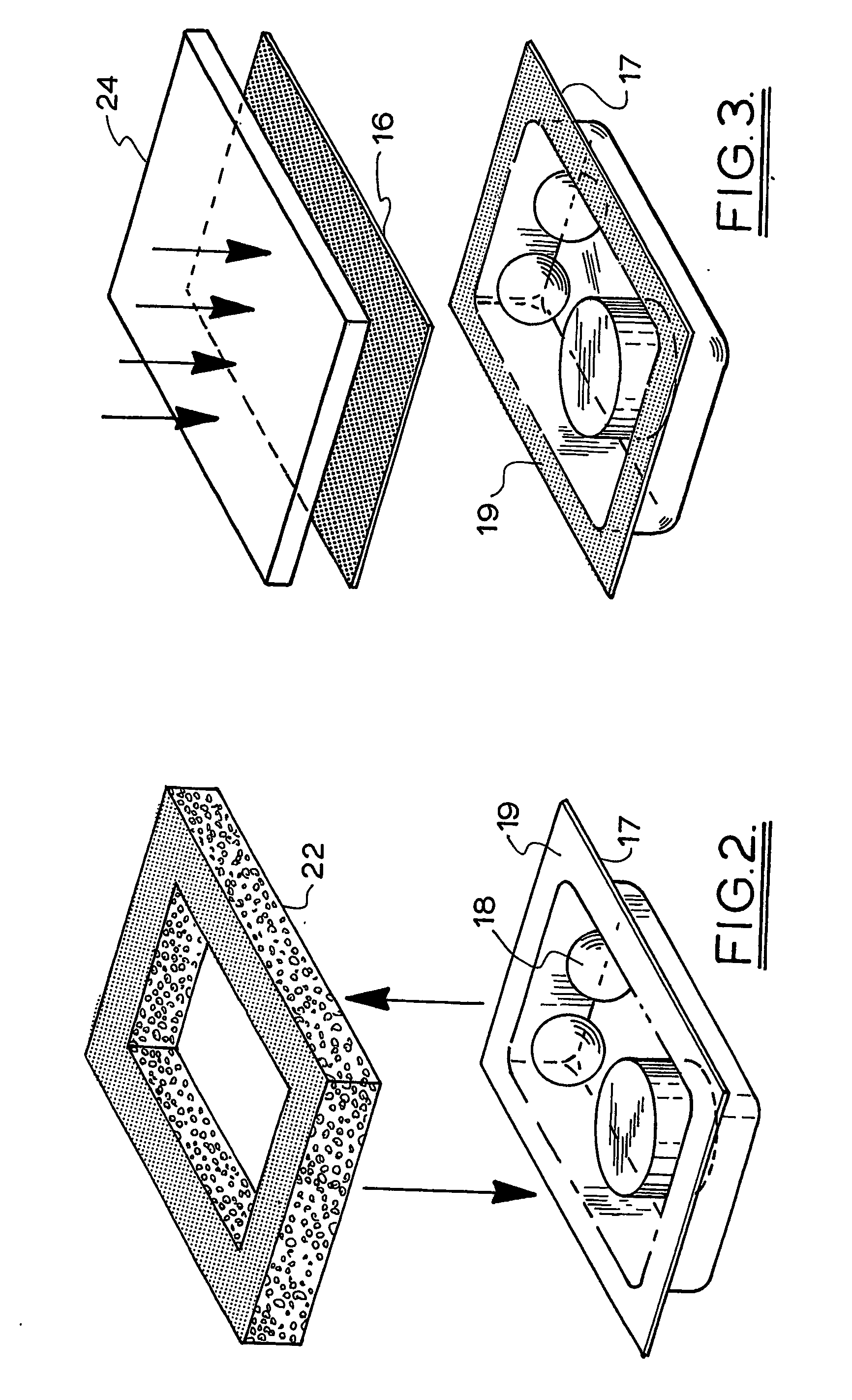

A blister package consists of a backing sheet (16) of cardboard, paper or plastic adhered to a blister (17) in which at least one or both of the backing sheet and the blister is made from a transparent water soluble thermoformable polymer composition. A tooth brush, cleaning utensil or garden utensil enclosed in the water soluble packaging material can be opened by placing it under running water. The packaging material is a starch or modified starch based polymer by direct contact with water, and that biodegrades in waste water. The preferred starch is a high amylose maize starch. The starch can also be derived from wheat, potato, rice, oats, arrowroot and pea sources. The backing sheet is adhered to water and applying the backing sheet with the use of a press plate (24).

Owner:PLANTIC TECH

Cation surface sizing agent and preparation method thereof

InactiveCN101649583AReduce manufacturing costPrevent penetrationWater-repelling agents additionPaper/cardboardAmylaseSizing

The invention provides a cation surface sizing agent and preparation method thereof. Raw materials are as follows by weight percent: 8-17% of styrene, 5-15% of butyl acrylate, 0.5-5% of acrylamide, 0.5-5% of N-hydroxymethyl acrylamide, 1-5% of methyl acryloyl ethyl trimethylammonium chloride, 2-8% of starch, 0.001-0.003% of amylase, 0.2-0.7% of organic acid, 0.2-0.8% of emulsifier, 1-5% of 27% hydrogen peroxide, 0.01-0.05% of iron dichloride, the balance water. The cation surface sizing agent is prepared by starch pasting, monomer pre-emulsion and emulsion polymerization. The invention is usedfor surface sizing of paper and achieves the aim of improving physical performances of paper such as water-resistance, ring crush compression resistance, surface strength and the like.

Owner:东莞市清正合成高新材料有限公司 +1

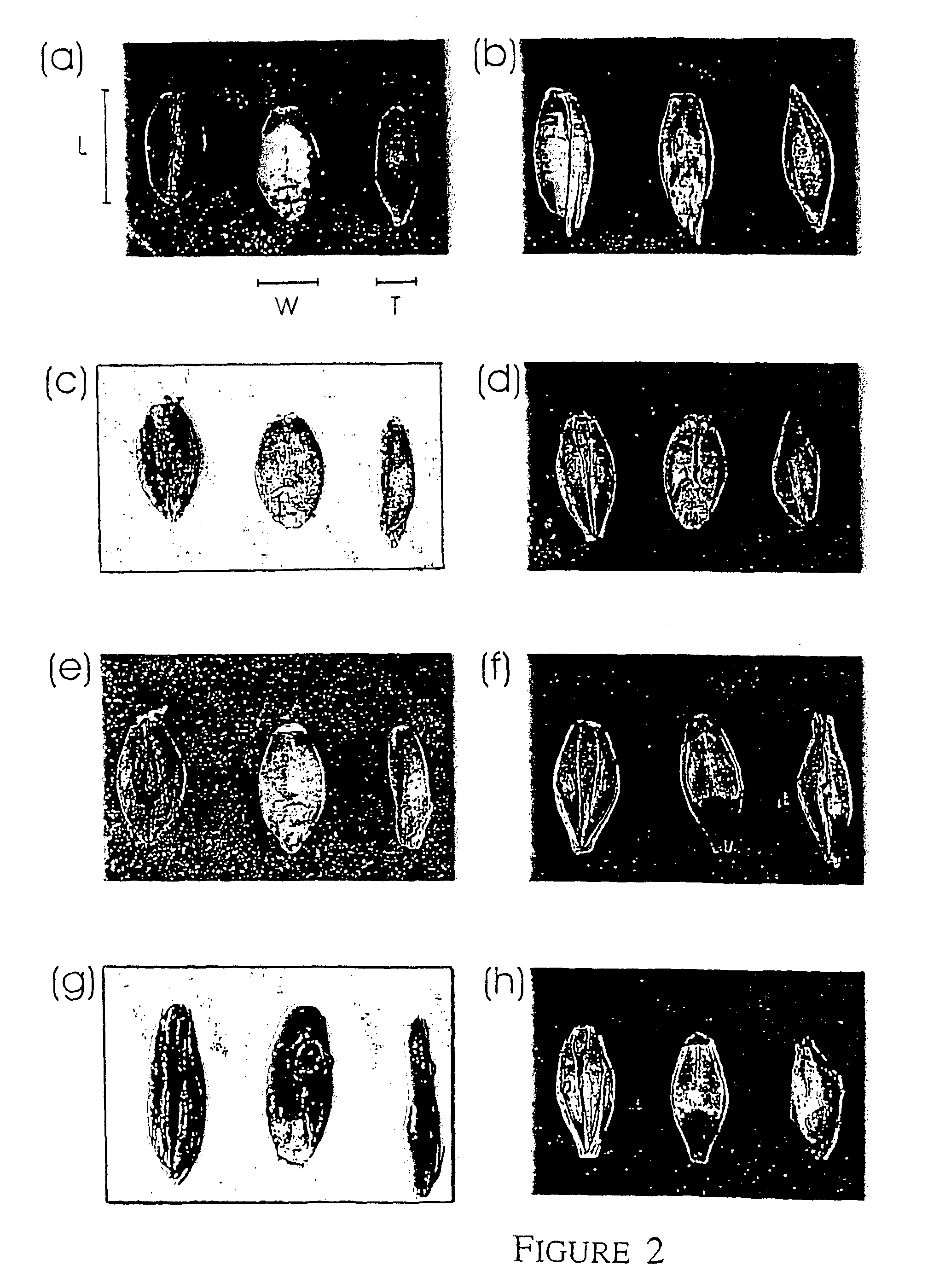

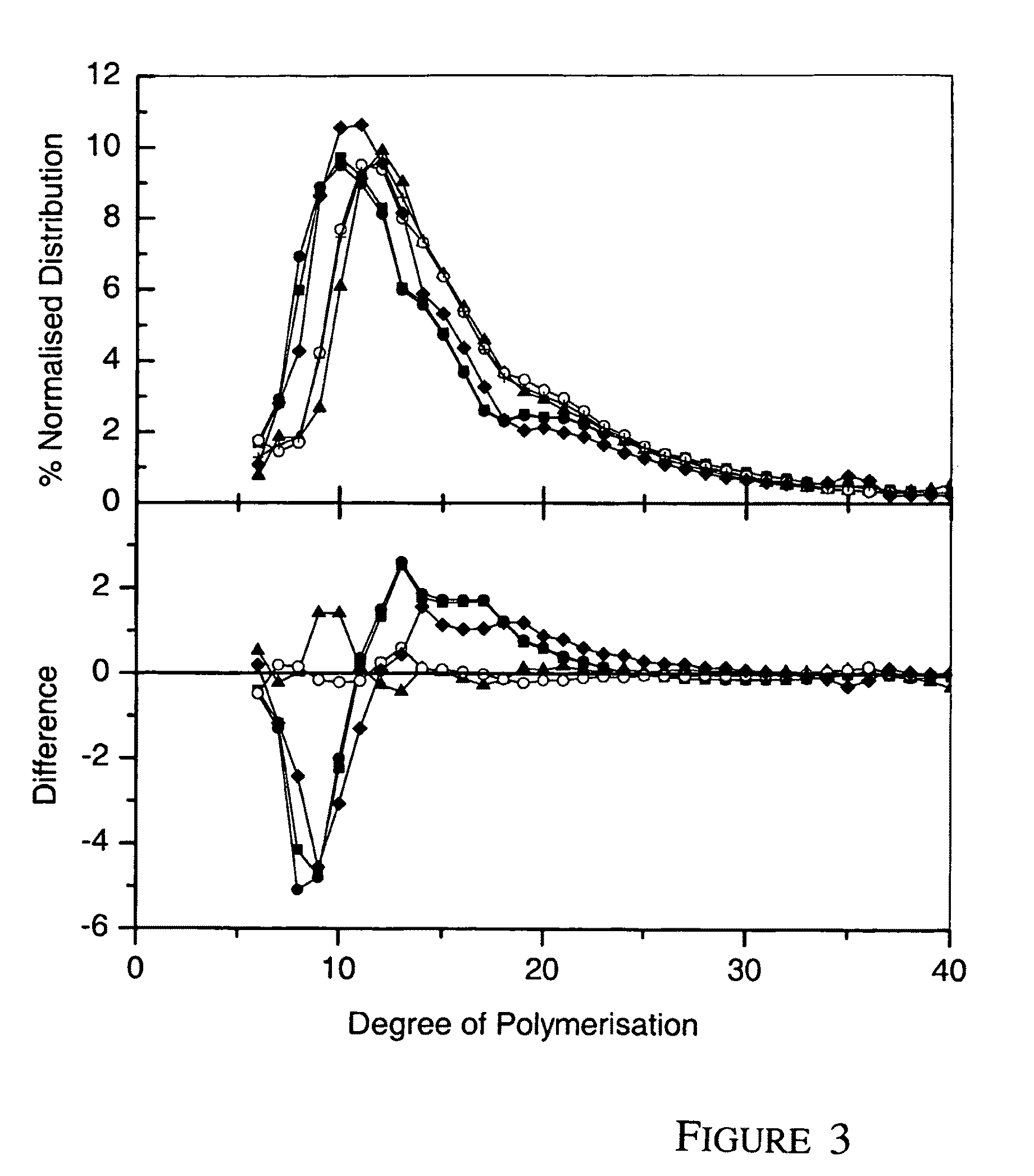

Barely with reduced SSII activity and starch and starch containing products with a reduced amylopectin content

InactiveUS8178759B2Improve the level ofReduce the temperatureBryophytesBaking mixturesAmylomaize StarchGlucan

Barley with reduced SSII activity has a starch structure with reduced amylopectin content and a consequent high relative amylose content. Additionally the grain can have a relatively high β glucan content. The structure of the starch may also be altered in a number of ways which can be characterized by having a low gelatinzation temperature but with reduced swelling. The viscosity of gelatinized starch of the starch is also reduced. There is a chain length distribution of the amylopectin content and a low crystallinity of the starch. The starch is also characterized by having high levels of lipid associated starch exhibiting very high levels of V form starch crystallinity. The dietary fiber content of the starch is high. This has desirable dietary and food processing characteristics.

Owner:THE HEALTHY GRAIN PTY LTD

Soft capsule nutritional supplement applicable to piglets and preparation method thereof

InactiveCN102125179ASufficient nutritionEasy to makeAnimal feeding stuffAccessory food factorsBiotechnologyAnimal science

Owner:TONGWEI

Yixinningshen tablet and its preparation method

InactiveCN101011468AImprove utilizationEasy to administerNervous disorderDrageesSide effectFine powder

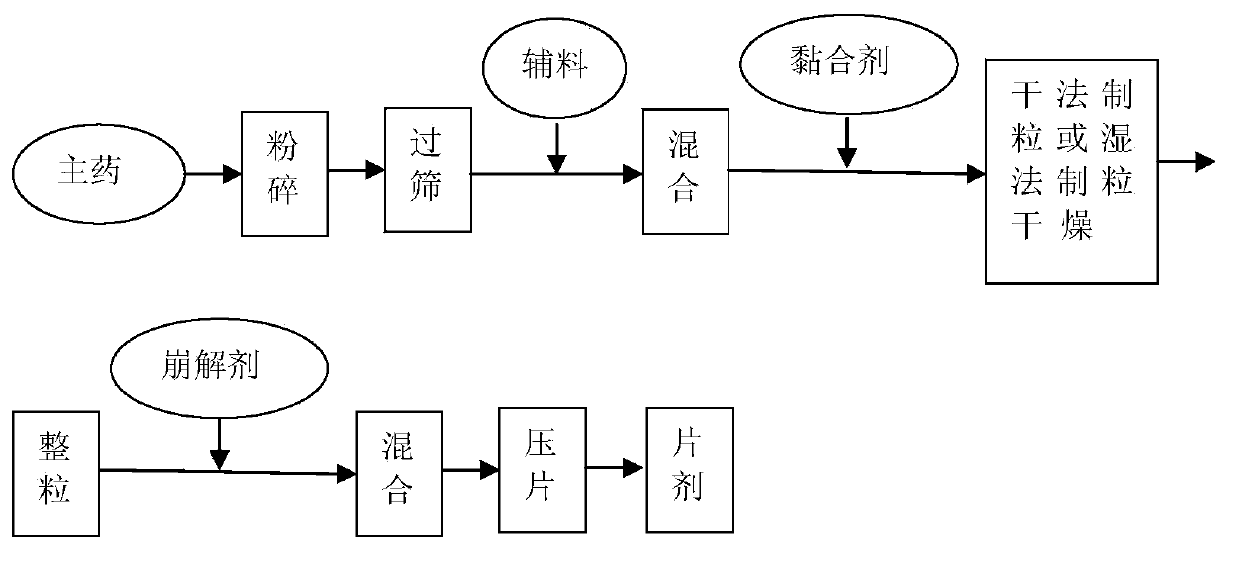

The invention relates to a method for preparing relieving mental stress tablet, which comprises 9-11g panaxoside, 995-1005g albizia flower, 495-505g schisandra fruit, and 495-505g lucid ganoderma; breaks the schisandra fruit into rough powder, adding 75% alcohol to be immerged for 30min, refluxing and extracting for two times while the first time costs 2.5h and the second time costs 2h, combining the extractive and recycling alcohol, concentrating into dense paste; adding water into albizia flower and lucid ganoderma to be boiled for two times, while the first costs 2h and the second costs 1.5h; filtering, combining the fluid liquors, concentrating into dense paste, combining the dense pastes, drying and breaking into fine powder, adding panaxoside, and 80-100g amidon, or adding 15-20g calcium sulfate, 10-15g pre-gelatinized amidon, and 55-65g amidon; using 35-55% alcohol or 8-15% syrup to prepare particles, drying, and adding 0.5-1% dolomol and 1% French chalk, mixing uniformly, pressing into 1000 tablets or 600 tablets, coating sugar package or film. The invention has high drug utilization without side effect.

Owner:LIAONING HUANREN PHARMA

Solid dispersion combination of EGCG (epigallocatechin gallate) with thermal stability and preparation method of solid dispersion combination and application in preparation of solid dispersion combination

The invention provides a solid alcohol solid dispersion combination of EGCG (epigallocatechin gallate) with thermal stability and sugar alcohols. The sugar alcohols include one or more ingredients comprising fructose, newtol, fructo-oligose, xylooligosaccharide, polydextrose, mannitol, cane sugar, glucose, resistant dextrin, sorbitol, maltose, isomalt, mannose oligomer, carbo wax, dextrin, cyclodextrin, hydroxyl-lpropyl-beta-cyclodextrin, microcrystalline cellulose, carboxymethylcellulose, pregelatinized starch, starch, starch sugar, lactose, sodium carboxymethyl starch, proteoglycan, sucralose, aspartame, acesulfame, stachyose, neotame and stevioside, and the sugar alcohols and the EGCG are in (12-80):1 in proportion by weigth. The invention further provides a preparation method of the solid dispersion combination and application in preparation of the solid dispersion combination. By the aid of the solid dispersion combination, the EGCG is effectively improved in stability.

Owner:南京润瞳畅达医药科技有限公司

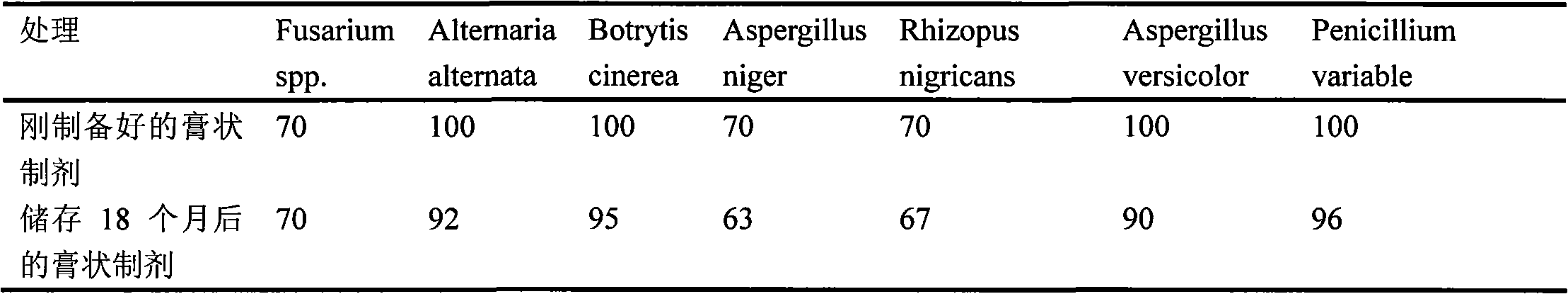

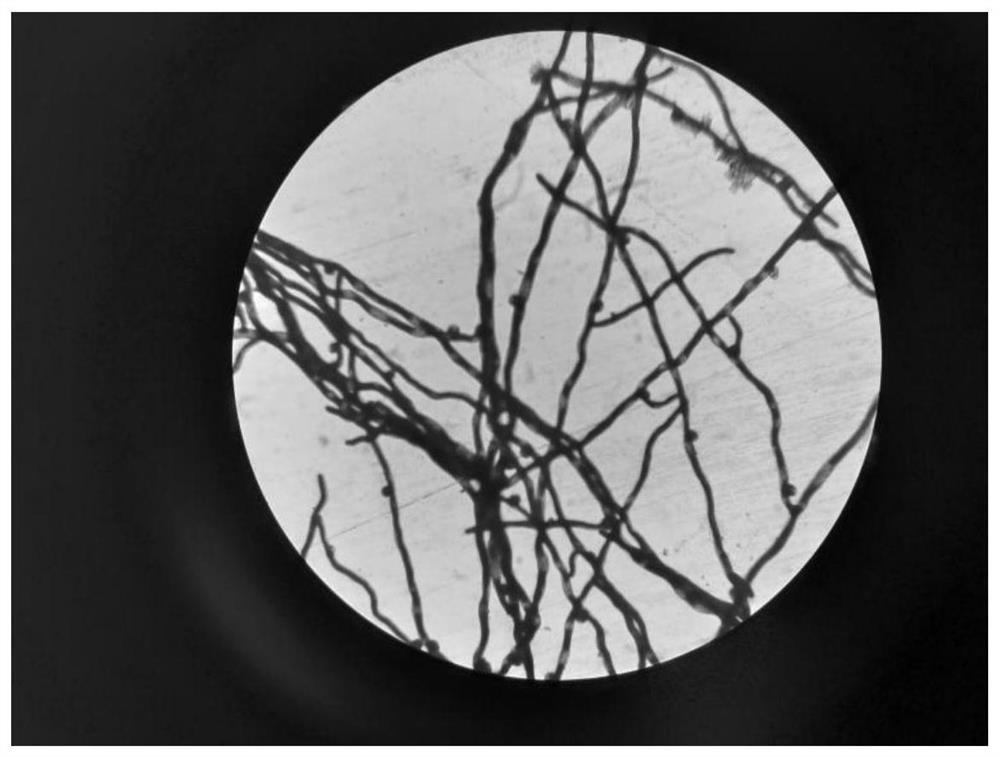

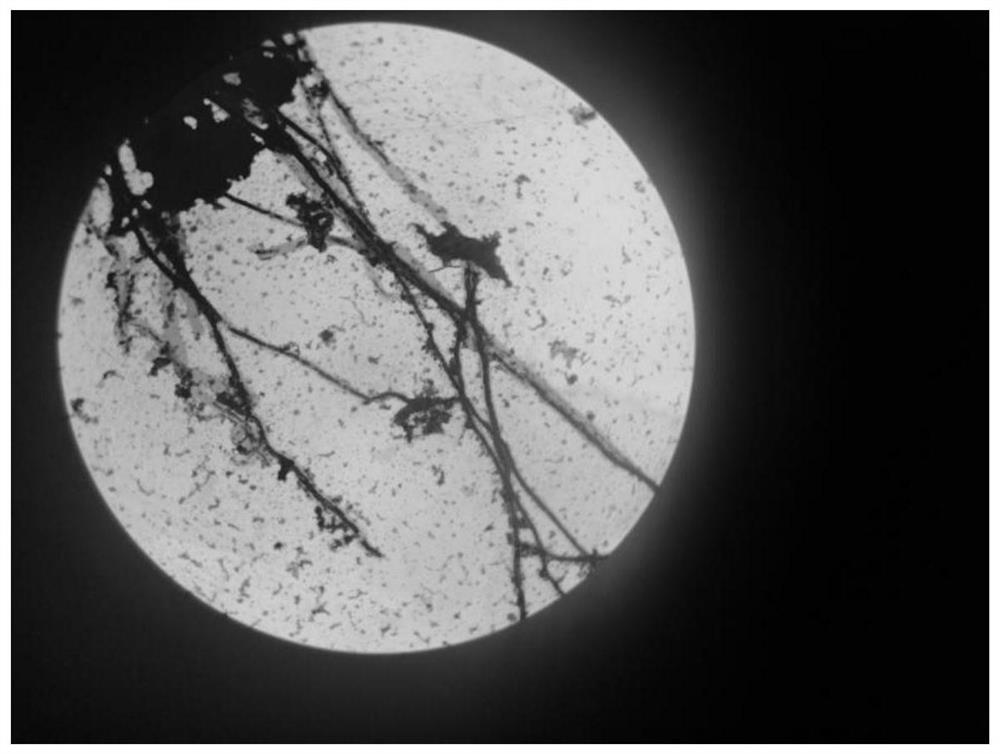

Paste dosage-form trichoderma biopesticide composite and preparation method thereof

ActiveCN101874484AImprove product qualityLong storage timeBiocideFungicidesHigh activityLiquid culture

The invention relates to a paste dosage-form trichoderma biopesticide composite and a preparation method thereof. The paste dosage-form trichoderma biopesticide composite comprises pesticide components and auxiliary materials, wherein the pesticide components include trichoderma hyphae and trichoderma chlamydospores, wherein the trichoderma chlamydospores are dispersed in the trichoderma hyphae. The paste dosage-form trichoderma biopesticide composite is characterized in that the auxiliary materials are starches which account for 5-10 percent of the total weight of the paste dosage-form trichoderma biopesticide composite. The preparation method comprises the following steps of: inoculating the trichoderma strains into a sterile liquid culture medium to carry out shake culture for 36-48 hours; taking out filtered trichoderma hyphae; regulating the pH of the trichoderma hyphae by using a hydrochloric acid; and adding a copper ion inhibitor and 5-10 percent of the starches for uniformly stirring so as to prepare the paste dosage-form trichoderma biopesticide composite. The paste dosage-form trichoderma biopesticide composite and a paste dosage-form biopesticide prepared by the methodhave the maximal disadvantages of stable product quality and long saving time, can be stored for 18 months at normal temperature and kept in high activity and can be stored for 3 years under the condition of refrigeration; and secondly, the invention has rarefied formula and advanced process and is beneficial to environmental protection without generating any waste water, waste gas and waste residues.

Owner:JIANGSU GENGYUN CHEM CO LTD

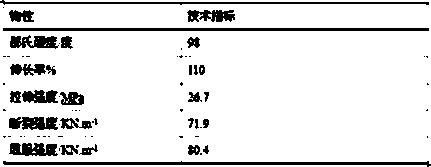

Hydroxypropyl Starch For Preparing Empty Capsules And Hydroxypropyl Starch-Based Soft Capsules

This invention comprising in hydroxypropyl starch for preparing empty capsules in alimentary and medical use, and hydroxypropyl starch-based soft capsules. This invention takes water as solvent, mix with propylene epoxide and catalyst for reaction, after washing, drying, hydroxypropyl starch is completed. The MS level of substitution of starch is around 2˜5, gelatinization point between 25˜60° C. After the hydroxypropyl starch is gelatinized by heating in water, a hydroxypropyl starch matrix soft capsule can be prepared. The invention consists in introducing hydroxypropyl by modifying the molecular chain of starch to improve the flexibility and hydrophilicity of starch. Therefore, a hydroxypropyl starch matrix soft capsule capable of preparing a flexible and disintegrating property is provided.

Owner:HUNAN ER KANG PHARMA

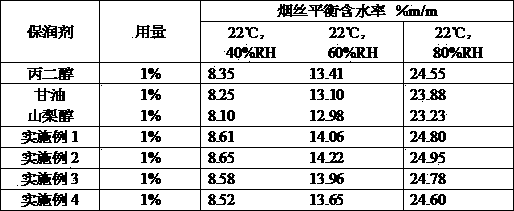

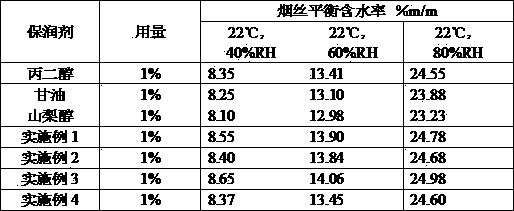

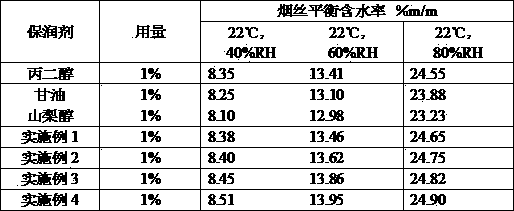

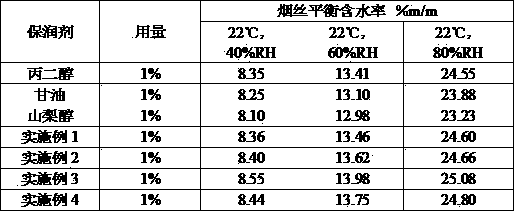

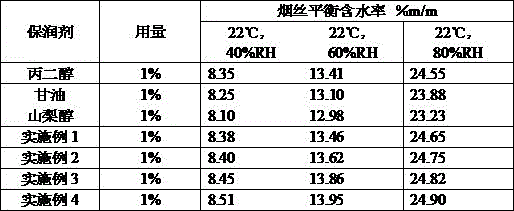

Preparation method and application of oxidized-carboxymethylated amyloid cigarette humectant

ActiveCN103772512AImprove processing resistanceReduce breakageTobacco treatmentBiotechnologySodium acetate

The invention relates to a preparation method and an application of an oxidized-carboxymethylated amyloid cigarette humectant. The humectant is prepared through oxidization and carboxymethylation modifications and by using the following raw materials: based on every 350 g of starch, 30-90 g of sodium hypochlorite, 800-2,400 g of an ethanol / water solution, 10-100 g of sodium hydroxide and 20-210 g of sodium chloroacetate. The preparation method is advantageous in that the starch is used as a raw material; the starch belongs to renewable resources, is widely available and has low cost; the starch is subjected to some oxidization modification and carboxymethylation modification, so that the modified starch has very strong water absorption and water retention capacities. The preparation method is environment-friendly and is low in cost. By spraying the humectants provided by the invention on tobacco leaves uniformly during a tobacco leaf-adding process, processing resistance of the tobacco can be increased; crushing of the tobacco leaves in the processing process can be reduced; tobacco leaf consumption of the cigarette is reduced; taste and flavor of the cigarette can be improved; stimulation of smoke can be alleviated; and effects for improving physical moisture preservation and sense moisture preservation can be achieved at the same time.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Preparation method and application of enzymolyzed-oxidized amyloid cigarette humectant

The invention relates to a preparation method and an application of an enzymolyzed-oxidized amyloid cigarette humectant. The humectant is prepared through enzymolysis and oxidation modifications and by using the following raw materials: based on every 350 g of starch, 5-120 mg of alpha-amylase, 400-1,200 g of an ethanol / water solution and 15-65 g of sodium hypochlorite. The preparation method is advantageous in that the starch is used as a raw material; the starch belongs to renewable resources, is widely available and has low cost; the starch is subjected to some enzymolysis modification and oxidation modification, so that the modified starch has very strong water absorption and water retention capacities. The preparation method is environment-friendly and is low in cost. By spraying the humectants provided by the invention on tobacco leaves uniformly during a tobacco leaf-adding process, processing resistance of the tobacco can be increased; crushing of the tobacco leaves in the processing process can be reduced; tobacco leaf consumption of the cigarette is reduced; taste and flavor of the cigarette can be improved; stimulation of smoke can be alleviated; and effects for improving physical moisture preservation and sense moisture preservation can be achieved at the same time.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

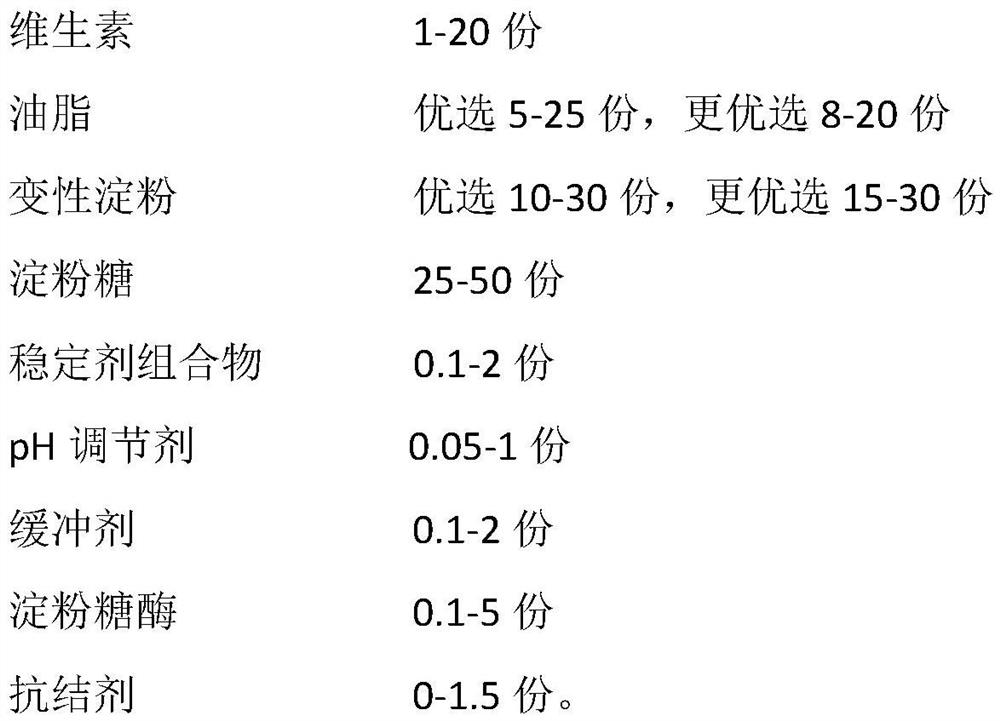

Photo-thermal stable vitamin microcapsule powder and preparation method thereof

ActiveCN112535293ASolve unstable puzzlesImprove stabilityVitamin food ingredientsFood homogenisationAmylaseGellan gum

The invention discloses photo-thermal stable vitamin microcapsule powder and a preparation method thereof. The photo-thermal stable vitamin microcapsule powder comprises the following raw and auxiliary materials: vitamins, grease, modified starch, starch sugar, a stabilizer composition, a pH regulator, a buffer agent, amylase and an anti-caking agent. The preparation method comprises the followingsteps of: dissolving the vitamins in the grease, and adding astaxanthin in the stabilizer composition; dissolving the modified starch in water, and adding the solution to obtain primary emulsion; dissolving the starch sugar in water, adding the amylase, controlling the DE value to be 70-85%, inactivating, adding enzymatic hydrolysate into the solution, and performing primary emulsification; dissolving gellan gum and konjac gum in the stabilizer composition in water, adding the solution, and performing secondary emulsification; and performing spray drying on the emulsion, thereby obtaining thevitamin microcapsule powder. The vitamin microcapsule powder obtained by the method provided by the invention has the characteristics of stable photo-thermal conditions, high embedding rate and the like.

Owner:INNOBIO CORP LTD

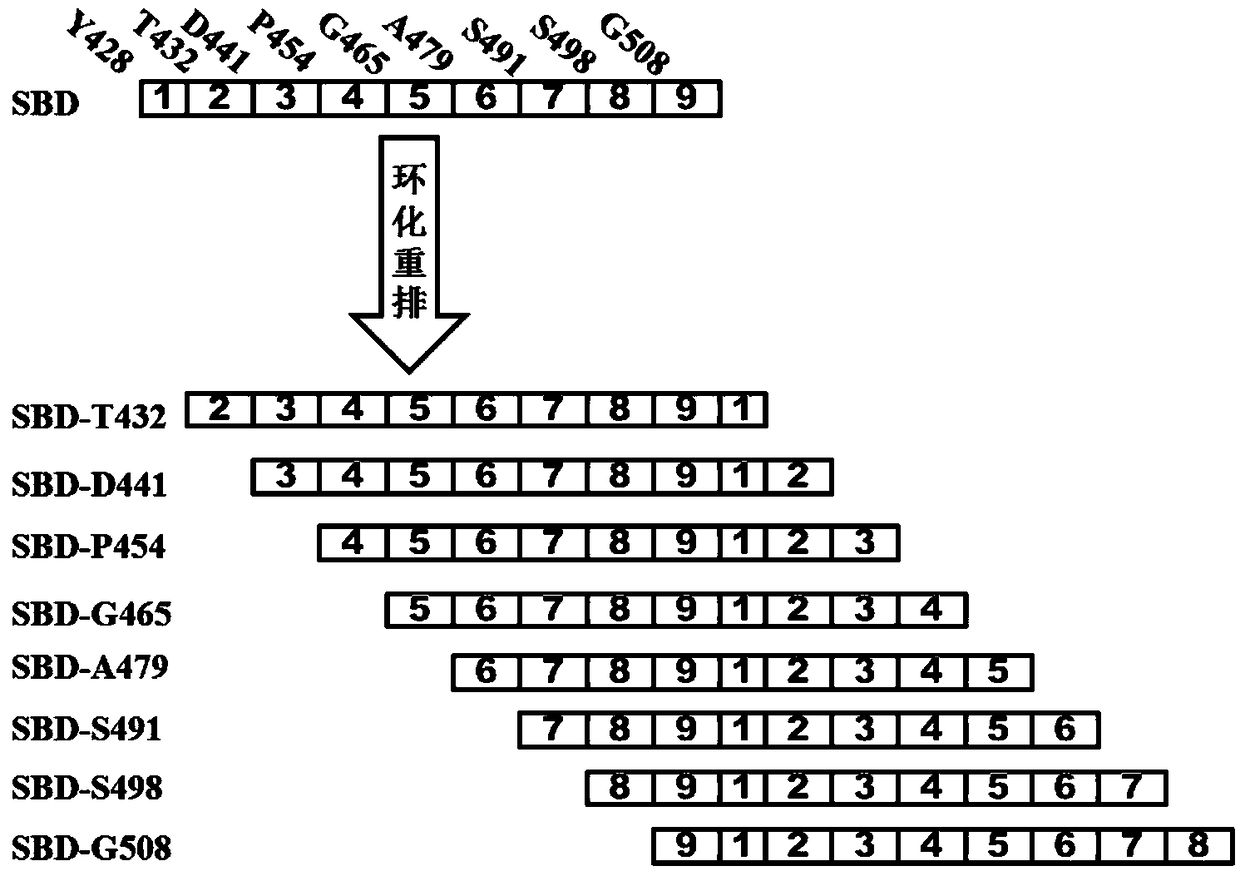

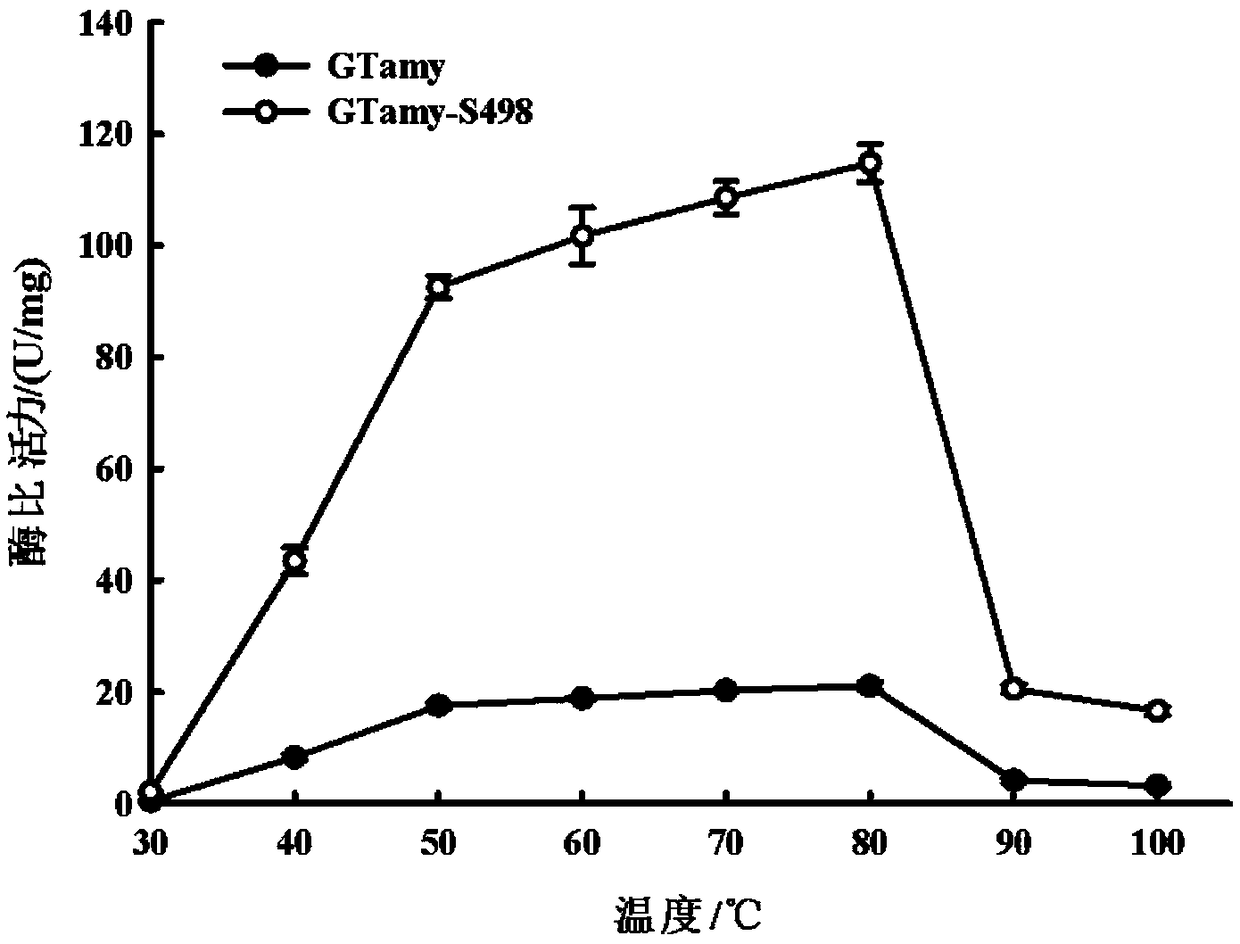

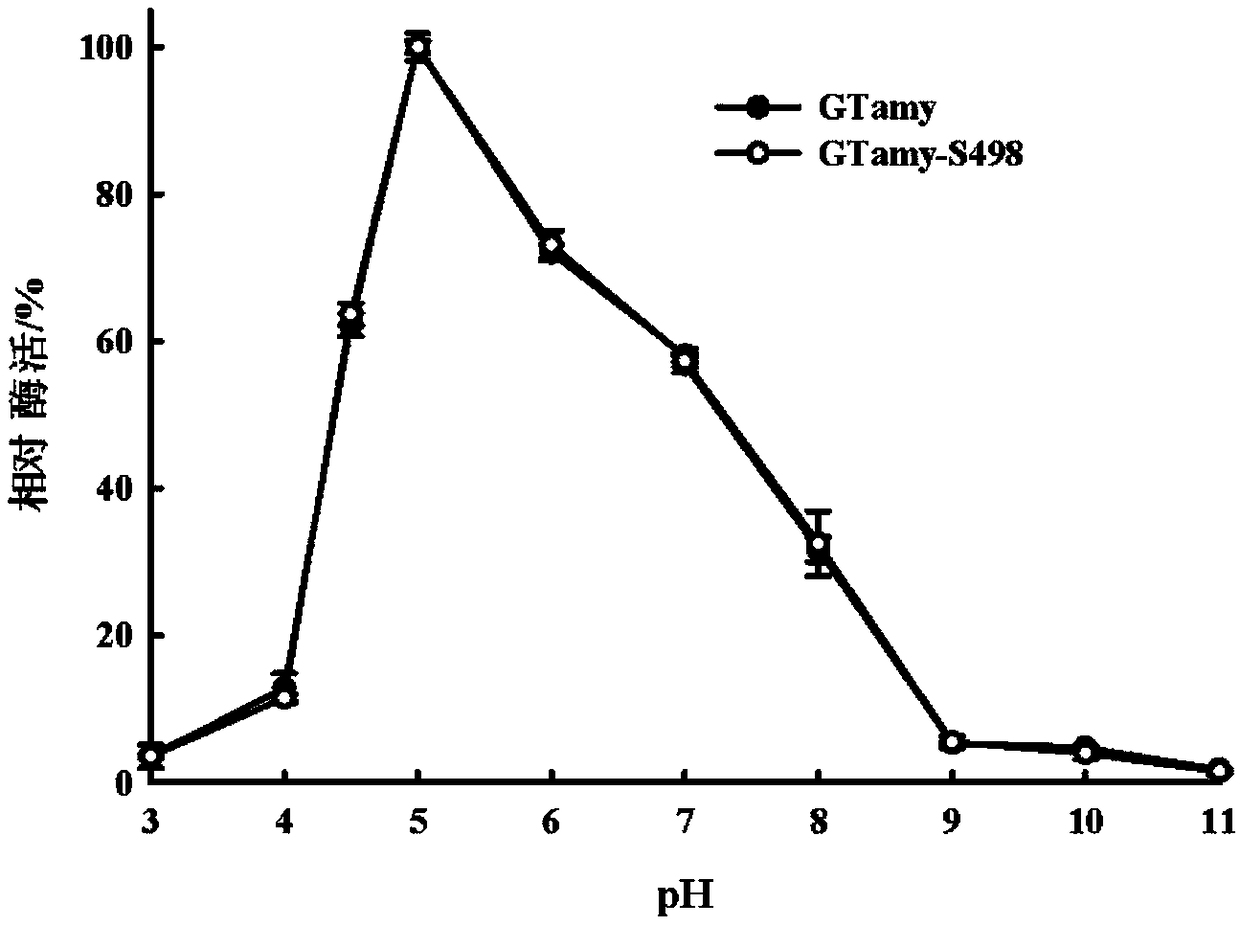

Thermophilic acidic raw starch alpha-amylase mutant capable of improving cornstarch degradation capability as well as preparation method and application thereof

ActiveCN108823186APromote degradationSimple processBacteriaMicroorganism based processesAlpha-amylaseMutant

The invention discloses a thermophilic acidic raw starch alpha-amylase mutant capable of improving the cornstarch degradation capability as well as a preparation method and application thereof and belongs to the field of genetic engineering and enzyme engineering. According to the thermophilic acidic raw starch alpha-amylase mutant, an SBD structure domain of raw starch alpha-amylase GTamy is subjected to cyclic rearrangement mutation; then SBD in the GTamy is replaced with an SBD cyclic rearrangement mutant, so as to construct a GTamy cyclic rearrangement mutant. The enzyme activity of the GTamy cyclic rearrangement mutant to the cornstarch is compared to screen a raw starch alpha-amylase mutant GTamy-S498 with the cornstarch degradation capability which is remarkably improved. The enzymeactivity of the raw starch alpha-amylase mutant GTamy-S498 provided by the invention on the cornstarch is improved to 114.77 U / mg from 21.08 U / mg of a control group (before mutation) and is improvedby 5.44 times. The cornstarch degradation capability of the raw starch alpha-amylase mutant GTamy-S498 is remarkably improved and the enzymatic property meets the requirements of a starch liquefactiontechnology and is more suitable for the starch liquefaction technology.

Owner:INST OF MICROBIOLOGY JIANGXI ACADEMY OF SCI

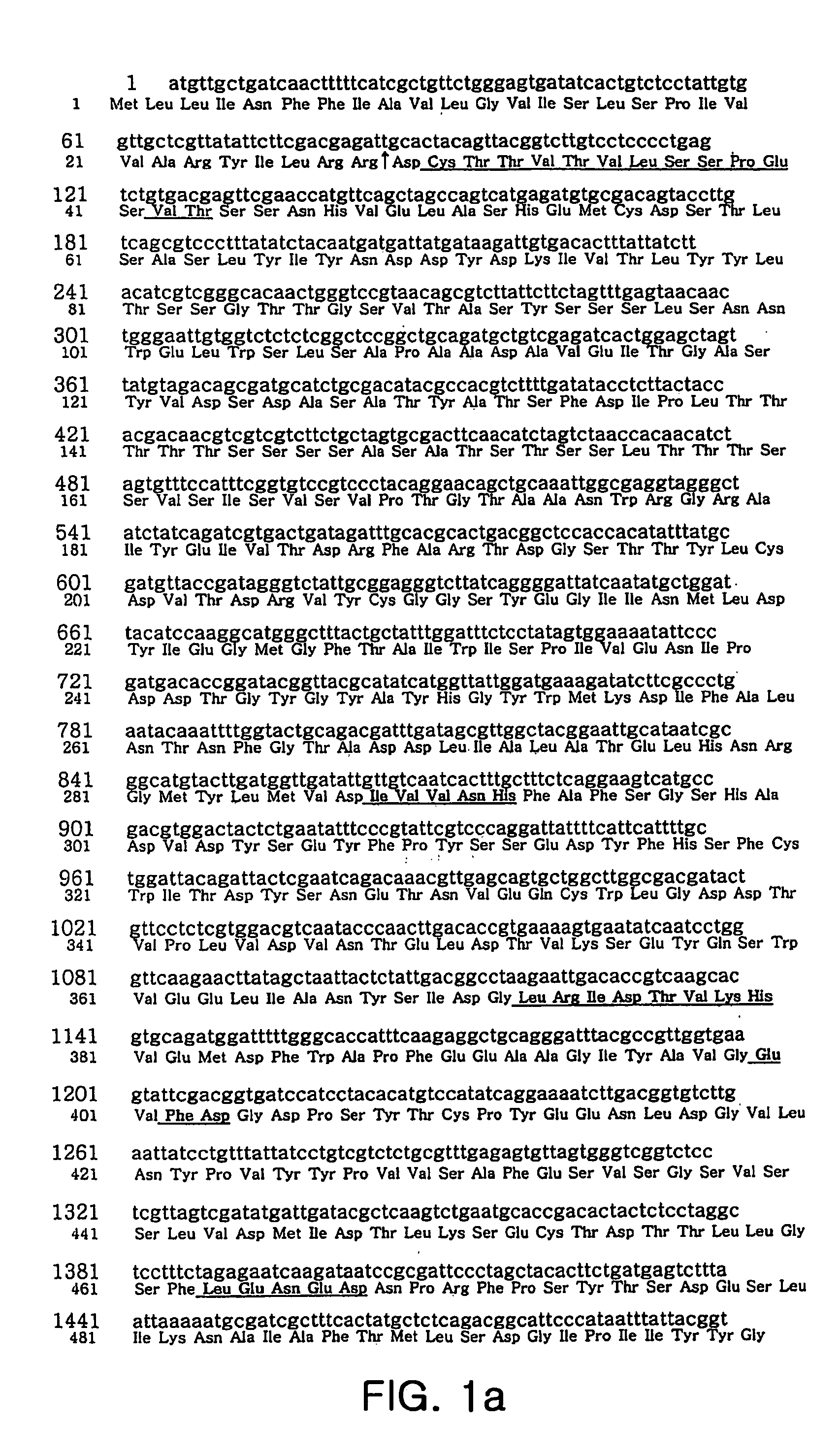

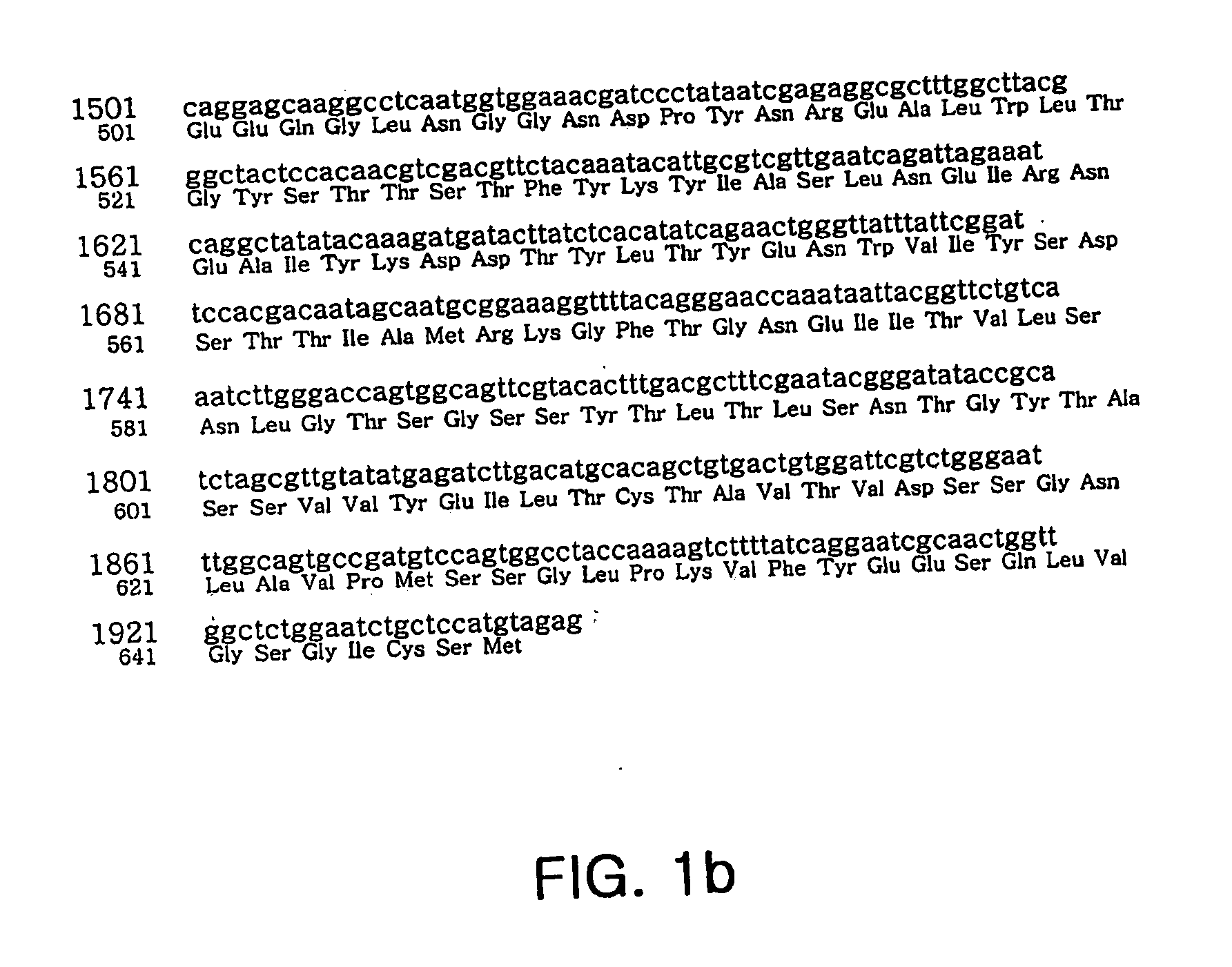

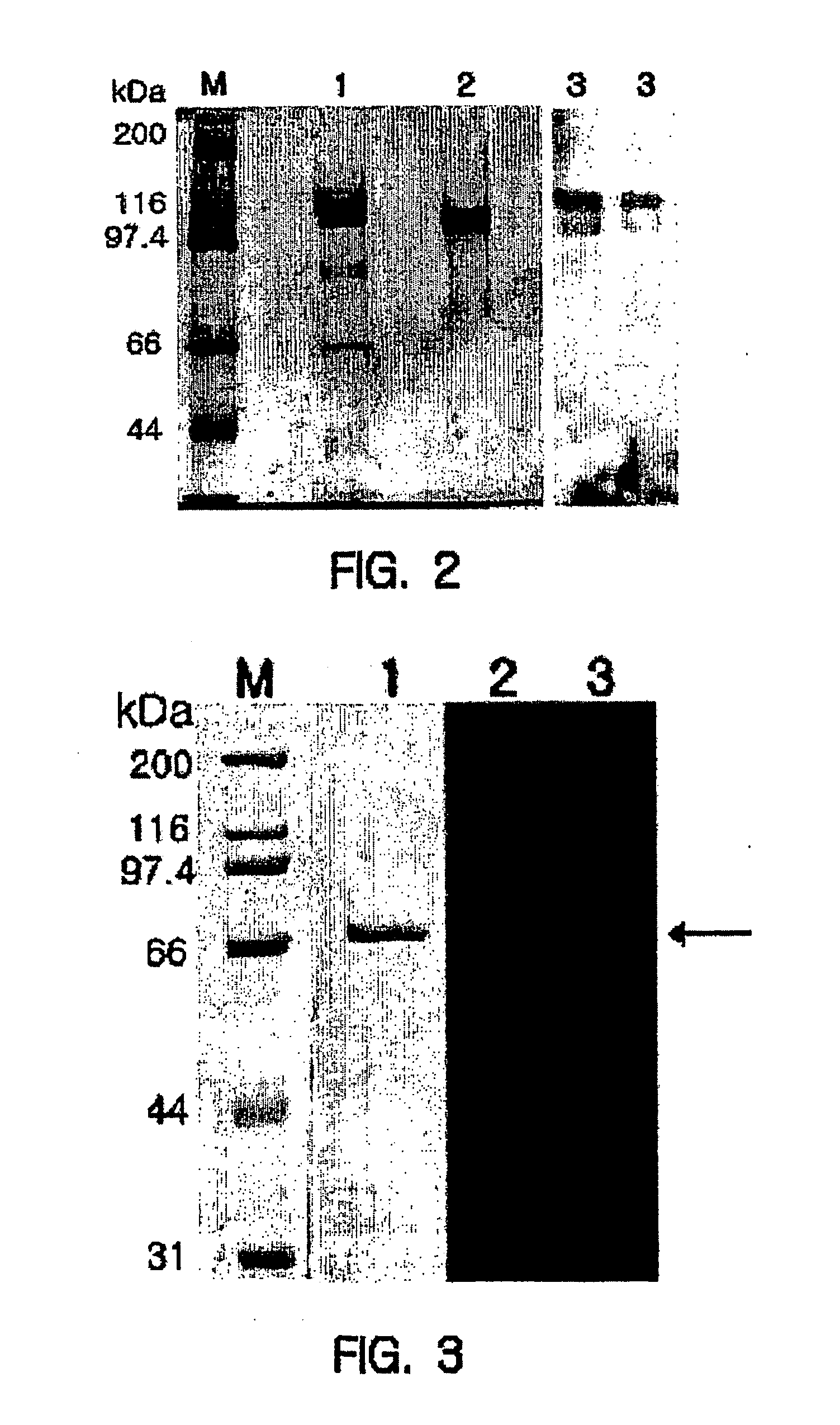

Protein with activity of hydrolyzing amylopectin, starch, glycogen and amylose, gene encoding the same, cell expressing the same, and production method thereof

Disclosed are an enzyme, having the amino acid sequence of SEQ. ID. No. 1 with the activity of hydrolyzing amylopectin, starch, glycogen and amylose, a gene encoding the enzyme, and a transformed cell expressing the gene. Also disclosed is a method of producing an enzyme capable of degrading amylopectin, starch, glycogen and amylose, which comprises culturing the cell, expressing the enzyme in the cell and purifying the enzyme. A composition comprising the enzyme is provided for removing dextran or polysaccharide contaminants during sugar production.

Owner:LIFENZA

Solid dispersion composition of levocarnitine as well as preparation method and medical application of solid dispersion composition

InactiveCN104739776AGood hygroscopicityQuality improvementOrganic active ingredientsGranular deliveryMannitolMaltose

The invention provides a solid dispersion composition of levocarnitine and a preparation method of the solid dispersion composition. Sugar alcohol substances include one or more of fructose, xylitol, polydextrose, fructo-oligose, mannitol, cane sugar, glucose, resistant dextrin, sorbitol, maltose, isomaltulose alcohol, manoligosaccharides, dextrin, cyclodextrin, hydroxypropyl-beta-cyclodextrin, microcrystalline cellulose, carboxymethylcellulose, hydroxypropyl methylcellulose, pre-gelled starch, starch, starch sugar, lactose, sodium carboxymethyl starch, protein sugar, sucralose, aspartame, acesulfame potassium, stachyose, Neotame and stevioside; the sugar alcohol substances are combined with the levocarnitine in a weight ratio of (13-50):1; the levocarnitine further comprises levocarnitine tartrate or levocarnitine hydrochloride. The solid dispersion composition has excellent moisture absorption resisting quality stability and is significant for the improvement of the product quality.

Owner:FUZHOU QIANZHENG PHARMA

Process for starch liquefaction

The present invention relates to a process for the liquefaction of starch present in a starch slurry comprising degraded starch and having a DE of from 0.05 to 9. Preferably, the invention relates to a process for the liquefaction of starch present in a starch slurry comprising degraded starch, said starch slurry having a high dry substance. Further preferably, the invention relates to a continuous process for liquefaction of starch present in a starch slurry comprising degraded starch and having a high dry substance.

Owner:CARGILL INC

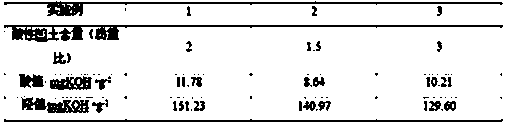

Polyurethane elastomer preparation method using starch liquefaction products

The invention discloses a polyurethane elastomer preparation method using starch liquefaction products. The polyurethane elastomer preparation method comprises the following steps: (1) putting a liquefying agent comprising polyethylene glycol 400 and glycerin into a container with the mass ratio of the polyethylene glycol 400 to the glycerin of 2:1, stirring and elevating the temperature to 150 DEG C; (2) adding an acid attapulgite catalyst into the container, adding starch into the container with the mass ratio of the starch to the liquefying agent of 6:1, stopping the reaction when the hydroxyl value range of the starch liquefaction products is 90 mgKOH / g to 170 mgKOH / g; (3) weighing a rubber vulcanizator, putting the rubber vulcanizator into the container, and adding acetone until complete dissolution; and (4) adding polyether and the starch liquefaction products into a acetone solution of the rubber vulcanizator, adding auxiliary agents and attapulgite, stirring evenly, then adding toluene diisocyanate (TDI), finally adding 1-2 drops of catalyst dibutyltindilaurate, stirring to foaming, and then obtaining polyurethane elastomer. The polyurethane elastomer preparation method is simple, and is suitable for industrial production, and the polyurethane elastomer has the advantages of high strength, good stability and strong water resistance.

Owner:JIANGSU WELLCARE HOUSEHOLD ARTICLES

Preparation method and application of acidolyzed-oxidized amyloid cigarette humectant

ActiveCN103772515AImprove processing resistanceReduce breakageTobacco treatmentBiotechnologySodium chlorate

The invention relates to a preparation method and an application of an acidolyzed-oxidized amyloid cigarette humectant. The humectant is prepared through acidolysis and oxidation modifications and by using the following raw materials: based on every 350 g of starch, 10-150 g of 37% concentrated hydrochloric acid, 400-1,200 g of a water solution and 20-70 g of sodium hypochlorite. The preparation method is advantageous in that the starch is used as a raw material; the starch belongs to renewable resources, is widely available and has low cost; the starch is subjected to some acidolysis modification and oxidation modification, so that the modified starch has very strong water absorption and water retention capacities. The preparation method is environment-friendly and is low in cost. By spraying the humectants provided by the invention on tobacco leaves uniformly during a tobacco leaf-adding process, processing resistance of the tobacco can be increased; crushing of the tobacco leaves in the processing process can be reduced; tobacco leaf consumption of the cigarette is reduced; taste and flavor of the cigarette can be improved; stimulation of smoke can be alleviated; and effects for improving physical moisture preservation and sense moisture preservation can be achieved at the same time.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

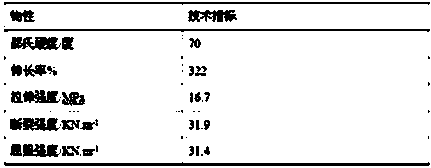

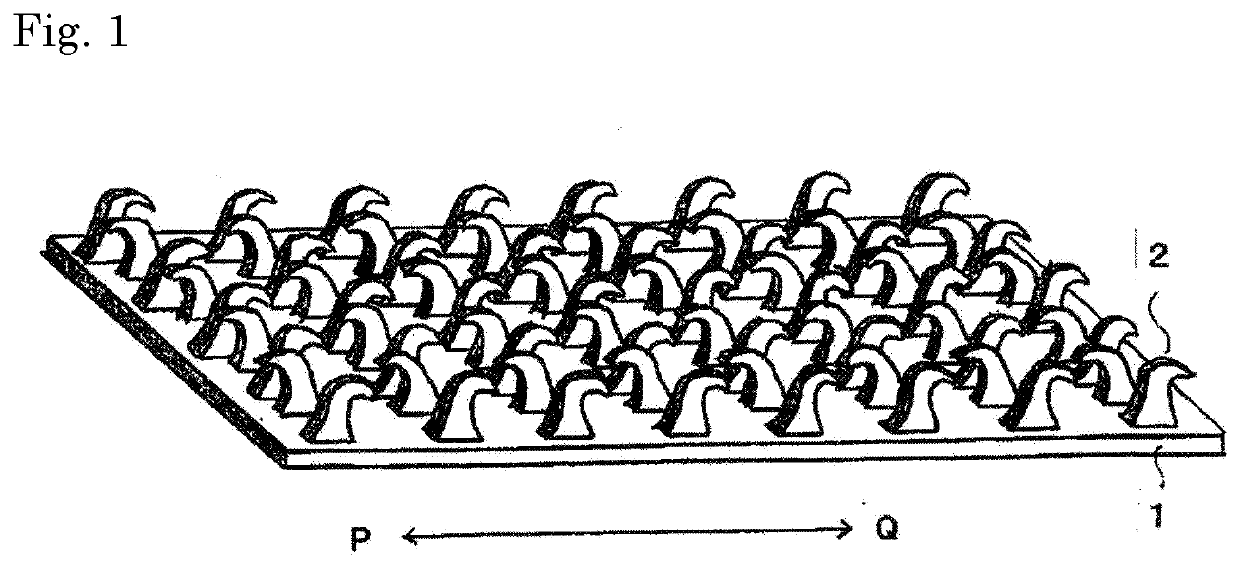

Biodegradable hook-type molded surface fastener with outstanding moldability

PendingUS20220175093A1Improve decomposition rateAvoid destructionDomestic articlesCoatingsPolymer scienceButanedioic acid

A molded hook surface fastener having a base plate and a large number of hook engaging elements projecting from a surface of the base plate, wherein both the base plate and the hook engaging elements is made of a resin mixture comprising polybutylene succinate (A) as a continuous phase and starch (B) as a dispersed phase, and satisfying the following requirements (1) to (3) simultaneously:(1) the dispersed phase comprises polyvinyl alcohol (C);(2) the starch (B) comprises a modified starch, and an amylose content of the starch (B) is 45% by weight or more; and(3) the hook engaging element tapers from a surface of the base plate toward a distal end portion and gradually bends from its middle such that the distal end portion faces a direction slightly approaching the surface of the base plate,is produced without breaking the hook engaging element during the pultrusion molding and is decomposed in the natural environment and does not bring about environmental destruction when discarded.

Owner:KURARAY FASTENING CO LTD +1

Oxcarbazepine tablets and preparation method thereof

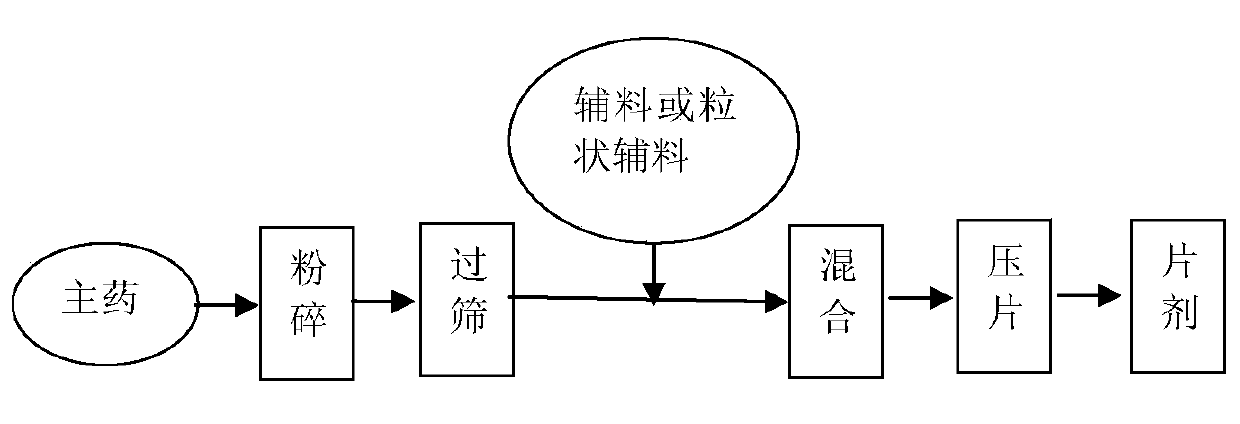

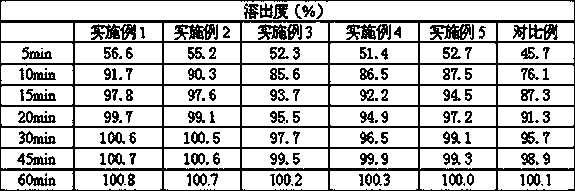

The invention discloses oxcarbazepine tablets and a preparation method thereof. The oxcarbazepine tablets comprise tablet cores and coating, wherein the tablet cores are obtained by directly pressing, and comprise the following components in percentage by weight in the oxcarbazepine tablets: 45 to 60 percent of oxcarbazepine, 5 to 10 percent of partially pregelatinized starch, 25 to 35 percent of starch and lactose compound, 3 to 7 percent of S-630 copovidone, 2 to 6 percent of cross-linked sodium carboxymethyl cellulose and 0.5 to 2.5 percent of sodium stearyl fumarate. By combining the characteristics that the oxcarbazepine is unstable in light and water, and is easy to deteriorate, the processes of adding water and drying are omitted in the preparation process of the oxcarbazepine, so that the production time is shortened, the production energy consumption is reduced, and manpower rand material resources are saved. The oxcarbazepine tablets disclosed by the invention have reasonable compositions, few impurities in a finished product, and obvious advantages of high dissolution rate and high tablet uniformity.

Owner:武汉人福药业有限责任公司

Novel method for preparing hollow carbon spheres

The invention relates to a novel method for preparing hollow carbon spheres. The method comprises specific steps as follows: (1) starch and a catalyst in the mass ratio being (10-1,000):1 are dissolved in a certain amount of water, and then the mixture is added to a stainless steel reaction kettle; (2) the stainless steel reaction kettle containing raw materials is placed into a heating furnace having a programmed heating function, the temperature is increased from the room temperature to 180-250 DEG C at the heating speed of 2-10 DEG C / min and kept for 1-8 h, then heating is stopped, and the reaction kettle is naturally cooled to the room temperature in the furnace; (3) a reaction liquid is subjected to suction filtration, products are washed with deionized water and dried at the temperature of 45-60 DEG C for 3-4 h finally, and finished products are obtained. The novel method for preparing the hollow carbon spheres has the advantages as follows: the starch, an amylolytic enzyme and the water are used as raw materials, and the hollow carbon spheres are prepared with a hydrothermal method; the method has the short reaction time and the simple technological process, the products, namely, the hollow carbon spheres, have good water solubility, and the hollow volume percentage is large.

Owner:海安常州大学高新技术研发中心

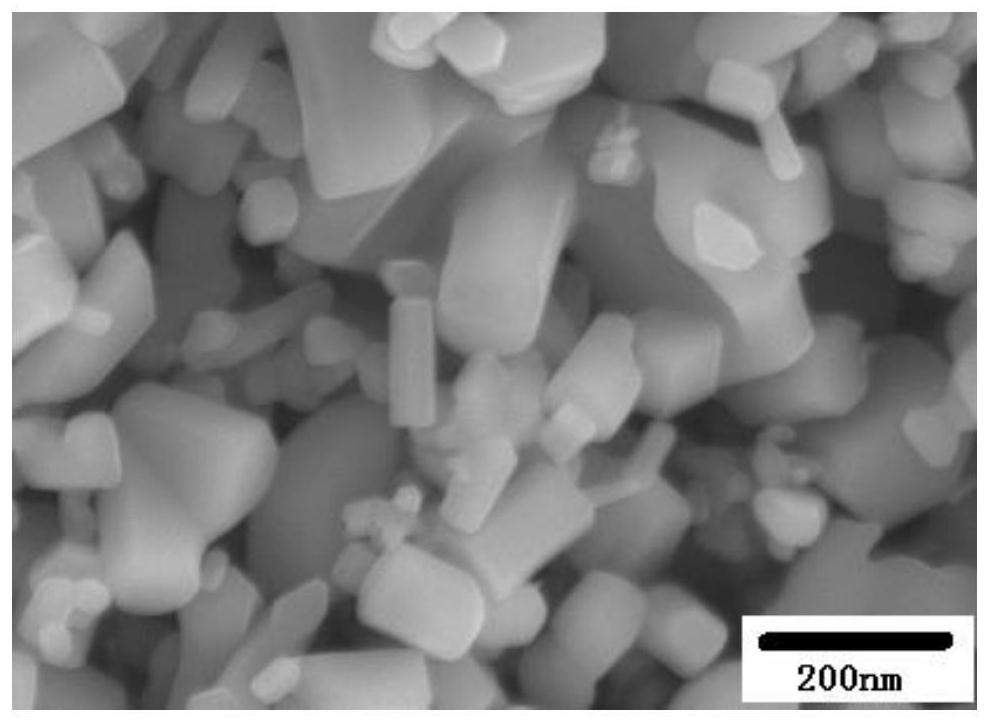

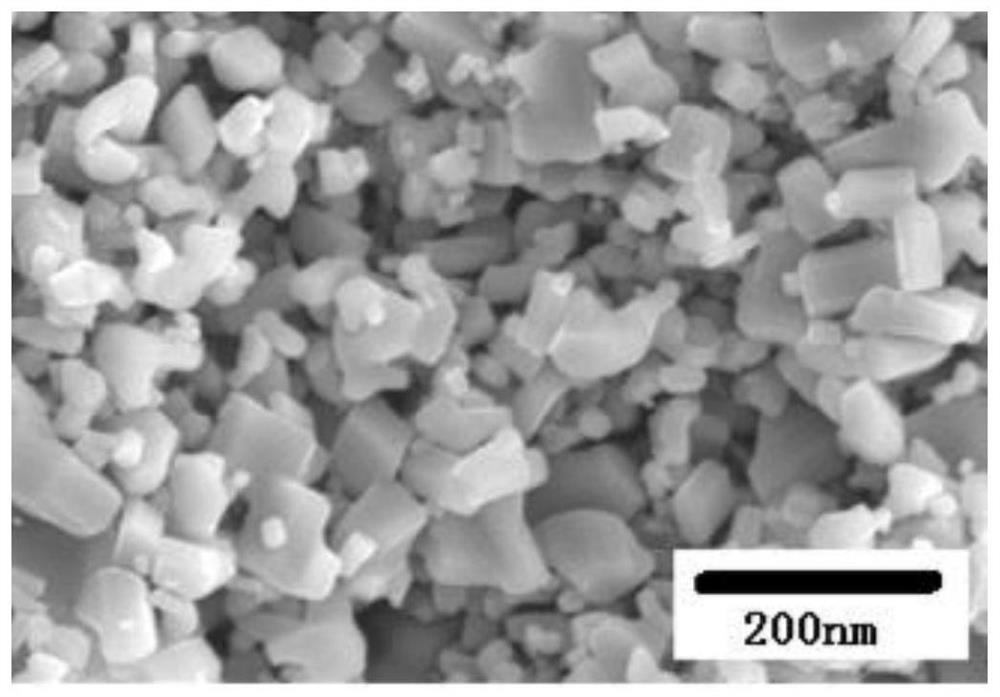

Preparation method of superfine zinc oxide powder

PendingCN113149061APromote hydrolysisPromote oxidationZinc oxides/hydroxidesNanotechnologyAmylasePhysical chemistry

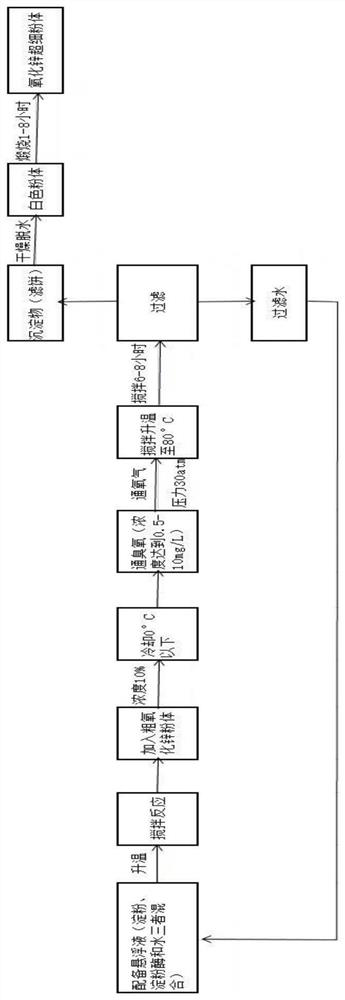

The invention discloses a preparation method of superfine zinc oxide powder, which comprises the following steps: step 1, preparing a suspension which comprises the following components: 5-10% of starch, 0.2-0.8% of amylase and the balance of water; step 2, putting the suspension prepared in the step 1 into a pressure kettle, heating to 60-80 DEG C, and then stirring for 20-50 minutes; step 3, adding 5-15% of coarse-particle zinc oxide powder into a pressure kettle in the step 2, enabling the concentration of the coarse-particle zinc oxide powder to reach 10%, and then cooling the coarse-particle zinc oxide powder to be below 0 DEG C; and step 4,introducing ozone into the suspension in the pressure kettle through an ozone generator.The preparation method is simple and convenient to operate, and compared with a traditional precipitation method for preparing superfine zinc oxide, a large amount of waste water and other solid waste are not generated, the used starch is natural, ozone can be obtained through an ozone generator, other chemical raw materials are not needed, and the particle size of the obtained product is controllable.

Owner:JIANGSU BEILIDE NOVEL MATERIALS

Functional nutrition bar based on resistant starch and combined polyphenol and preparation method thereof

PendingCN111011438AAdd flavorGreat tasteDough treatmentBaking processesBiotechnologyNutritive values

The invention relates to a functional nutrition bar based on resistant starch and combined polyphenol and a preparation method thereof. The nutrition bar is prepared by using the following raw materials: starch, resistant starch, starch-bound polyphenol, butter, soybean meal, eggs, nuts, preserved fruits, maltose, fructo-oligosaccharide, isomaltooligosacharide, inulin, salt, baking powder and thelike. In the baking process, materials are shaped at low temperature and then the shaped materials are baked and ripened at a medium-high temperature; and then a gradient temperature-changing baking process of low-temperature uniform coloring is adopted, so that the flavor of the product is effectively optimized and the taste and color of the finished product are improved. The nutrition bar disclosed by the invention is prepared by primary deep processing of a medicinal-edible substance primary product taking starch as a main component; the preparation process is simple; raw materials are richand easily available; the product forms are flexible; the nutrition value is great; and the functional nutrition bar as the relatively good functionality and relatively broad market prospects.

Owner:JIANGXI UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

Hericium erinaceus full-nutrition fed-batch semi-continuous fermentation method

The invention discloses a hericium erinaceus full-nutrition fed-batch semi-continuous fermentation method. The method comprises seed tank culture and fermentation tank culture, and is characterized in that an adopted seed culture medium comprises 1.3-2.0% of soybean meal, 0.4-0.6% of peptone, 2.8-3.2% of glucose, 0.12-0.18% of KH2PO4, 0.07-0.08% of MgSO4 and 0.16-0.18% of a defoaming agent; wherein the fermentation medium is prepared from 2.8-3.5% of bean pulp, 0.8-1.2% of glucose, 2.8-3.2% of molasses, 1.8-2.2% of corn starch, 18-22mg / L of amylase and 0.1% of a defoaming agent, the bean pulp in the seed medium is residue-free bean pulp, and the bean pulp in the fermentation medium is residue-free bean pulp. According to the method, the growth speed of hericium erinaceus thalli is increased, the yield of hyphae is increased, the fermentation time is shortened, and the content of polysaccharide and polypeptide is high.

Owner:JIANGSU SHENHUA PHARMA

Enzyme preparation for improving bread gluten strength

PendingCN111321131AImprove organizational structureHigh in sugarDough treatmentHydrolasesBiotechnologyAmylase

The invention provides an enzyme preparation for improving bread gluten strength. The preparation comprises the following raw materials in percentage by mass: 1%-2.5% of amylase, 0.5%-2% of hemicellulase, 0.5%-2% of phospholipase, 1%-2% of ascorbic acid and the balance of starch. The amylase, the hemicellulase and the phospholipase constitute the complex enzyme preparation. Baking quality of breadcan be improved and aging of fermented baked flour products can be effectively delayed by the synergistic effect of the compound enzymes in an optimized proportion in the enzyme preparation.

Owner:中山市南方新元食品生物工程有限公司 +2

Method for preparing starchy cigarette humectant by enzymatic hydrolysis and carboxymethylation and use of starchy cigarette humectant

ActiveCN103772514AImprove processing resistanceReduce breakageTobacco treatmentSodium chloroacetateIrritation

The invention discloses a method for preparing a starchy cigarette humectant by enzymatic hydrolysis and carboxymethylation and a use of the starchy cigarette humectant. The starchy cigarette humectant is prepared from 350g of starch, 5-120mg of alpha-amylase, 400-1200g of an ethanol / aqueous solution, 30-120g of sodium hydroxide and 50-230g of sodium chloroacetate by enzymatic hydrolysis and carboxymethylation. The method utilizes starch as the raw material and starch is a renewable resource and has a wide resource and a low price. Through enzymatic hydrolysis modification and carboxymethylation modification of starch, the modified starch has very strong water absorption and water retention capability, is environmentally friendly and has a low cost. The starchy cigarette humectant is uniformly sprinkled on the tobacco leaf in a tobacco leaf processing process so that tobacco leaf processing resistance is improved, crushed tobacco leaves in the processing process are reduced, cigarette tobacco leaf consumption is reduced, a taste and mouth feel are improved, smoke irritation is reduced and physical moisture retention and sensorial moisture retention effects on tobacco are improved simultaneously.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Double-system veneering gluing method for carton production

PendingCN111363495AExcellent adhesionReduce complaintsLiquid surface applicatorsNon-macromolecular adhesive additivesMaterials sciencePolymer

The invention relates to the technical field of carton gluing. The invention discloses a double-system veneering gluing method for carton production. The method comprises the following steps of (1) introducing 880-1100 kg of water into a glue storage barrel, then introducing 11-14 kg of glue powder into the glue storage barrel, adding 160-200 kg of starch, and finally adding 20-25 kg of caustic soda flakes to obtain a mixed solution A, and 2) starting a stirring device, and stirring the mixed solution A prepared in the step 1) for 3-5 minutes to obtain a fully mixed solution B. According to the double-system veneering gluing method for carton production, starch is added in the glue production process, starch is a polymeric carbohydrate, the polysaccharide is composed of a single type of sugar unit, the basic composition unit of the starch is alpha-D-glucopyranose, a covalent polymer formed by connecting glucose after water molecules are removed through glycosidic bonds is a starch molecule, the starch becomes turbid gradually after being placed in a thin paste state for a certain period of time, and finally insoluble white precipitate is generated.

Owner:宁夏和瑞包装有限公司

A kind of fermentation medium for producing doramectin and the production method of doramectin

ActiveCN109576196BReduce inhibitionControl concentrationBacteriaMicroorganism based processesAmylaseYeast

The invention relates to a fermentation medium for producing doramectin and a production method of doramectin. The composition of the fermentation medium includes: starch 100-140g / L, amylase 0.1-0.2g / L, soybean cake powder 12-18g / L, cottonseed cake powder 12-18g / L, yeast powder 0.5-1.5g / L , 2,2-methylbutyric acid 0.01-0.2g / L, cyclohexanecarboxylic acid or sodium cyclohexanecarboxylic acid 0.2-0.4g / L. The present invention significantly improves the fermentation level of doramectin by improving the fermentation medium and the production method of doramectin. After 370 hours of fermentation, the titer reaches 3545 μg / ml, and the whole production process is simple and easy to operate, which is beneficial to industrial production .

Owner:NEW FOUNDER HLDG DEV LLC +2

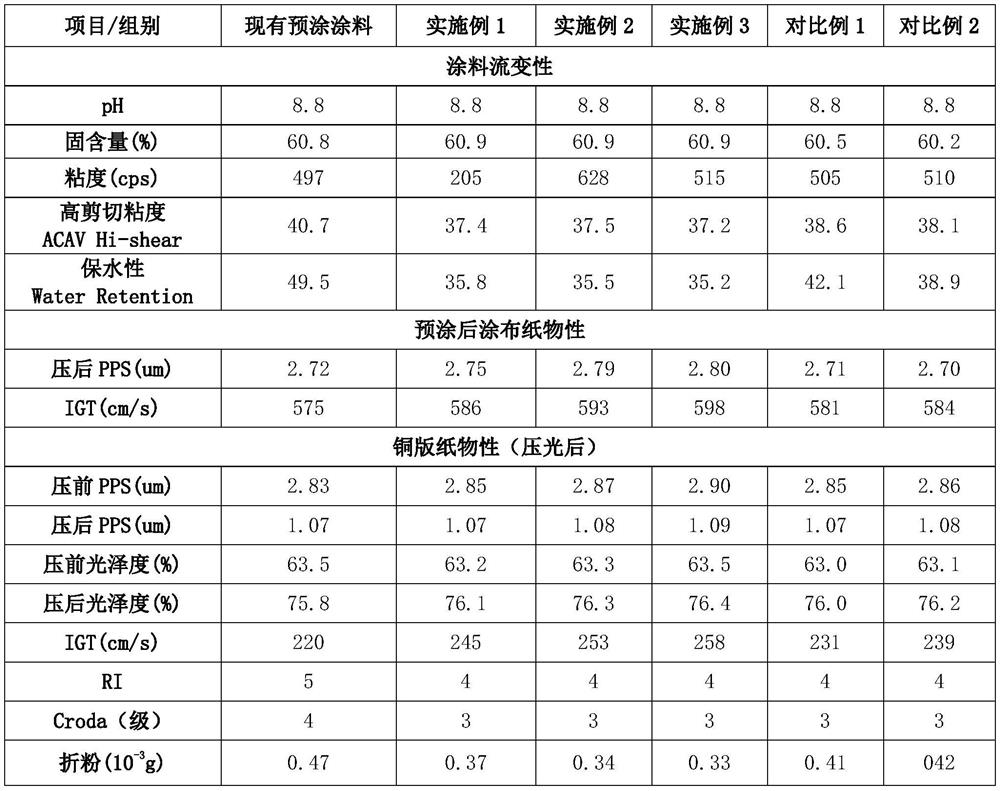

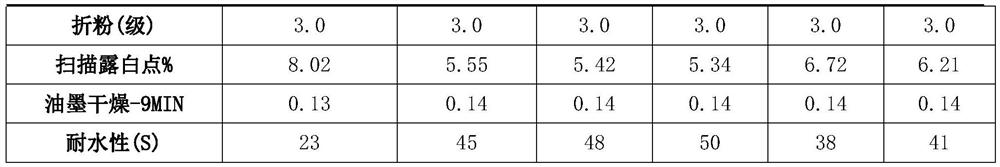

A kind of biological latex for coating, pre-coating paint and preparation method thereof

ActiveCN108677610BEasy to degradeImprove rheologyPaper/cardboardPulp material addition processesBiotechnologyAmylase

The invention provides coating biological latex, precoating paint and a preparation method of precoating paint. The biological latex is prepared from the following raw materials of starch, amylase anda biological intermediate, wherein the biological intermediate is prepared from the following raw materials of itaconic acid, polypropylene glycol and hydrogen peroxide. Compared with the existing paint, the precoating paint prepared by the biological latex disclosed by the invention has a good rheological property and a better water retention capacity; furthermore, the precoating paint has lowerand stabler high shear viscosity, so that a large high-speed paper machine has good operation performance. In addition, after the precoating paint disclosed by the invention is coated, the physical property of finished paper is obviously improved; IGT of the finished paper is remarkably improved, water resistance of the finished paper is obviously improved, and coated paper has better printing performance. The coated paper is suitable for a high-speed printing machine, layering and bubbling in a printing process are avoided, and the light spot phenomenon after printing is avoided.

Owner:HAINAN JINHAI PULP & PAPER

Preparation method and application of acid-decomposed-oxidized starch-based humectant for cigarettes

ActiveCN103772515BImprove processing resistanceReduce breakageTobacco treatmentBiotechnologySodium chlorate

The invention relates to a preparation method and an application of an acidolyzed-oxidized amyloid cigarette humectant. The humectant is prepared through acidolysis and oxidation modifications and by using the following raw materials: based on every 350 g of starch, 10-150 g of 37% concentrated hydrochloric acid, 400-1,200 g of a water solution and 20-70 g of sodium hypochlorite. The preparation method is advantageous in that the starch is used as a raw material; the starch belongs to renewable resources, is widely available and has low cost; the starch is subjected to some acidolysis modification and oxidation modification, so that the modified starch has very strong water absorption and water retention capacities. The preparation method is environment-friendly and is low in cost. By spraying the humectants provided by the invention on tobacco leaves uniformly during a tobacco leaf-adding process, processing resistance of the tobacco can be increased; crushing of the tobacco leaves in the processing process can be reduced; tobacco leaf consumption of the cigarette is reduced; taste and flavor of the cigarette can be improved; stimulation of smoke can be alleviated; and effects for improving physical moisture preservation and sense moisture preservation can be achieved at the same time.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

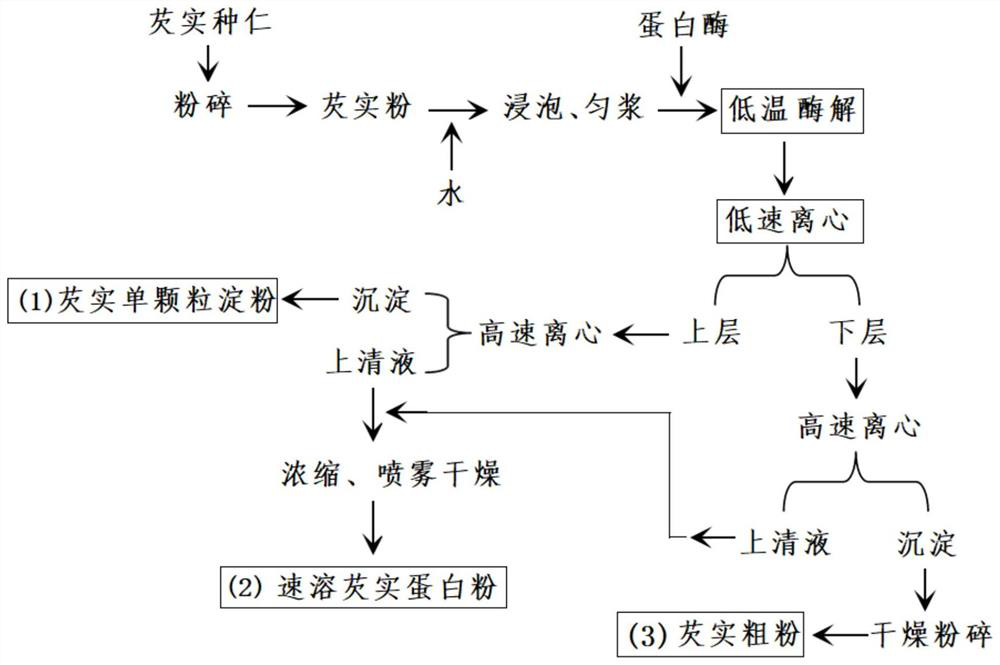

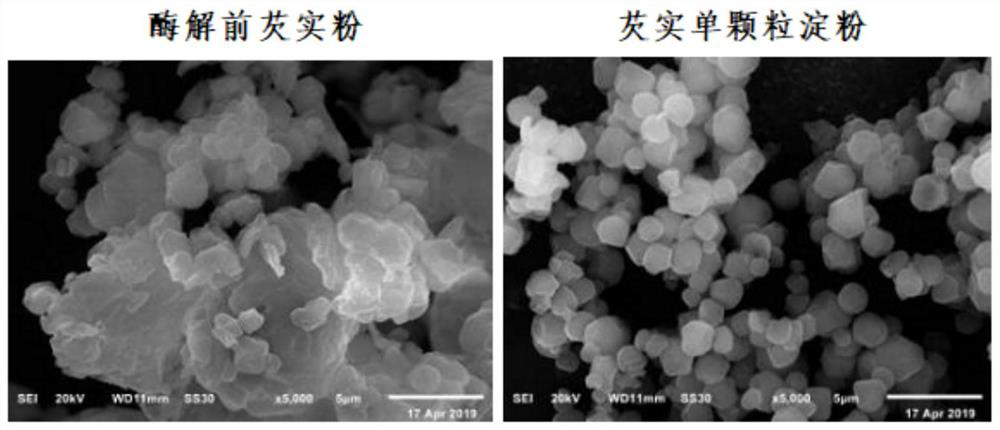

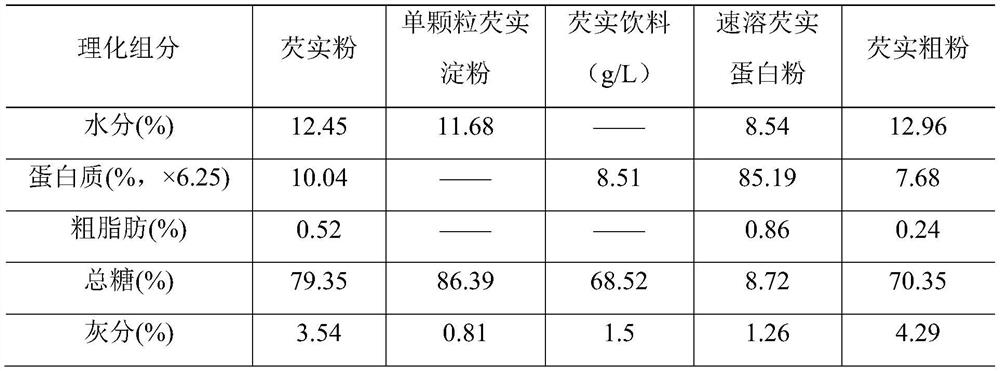

A kind of enzymatic synchronous processing method of single granule gorgon starch and related products

ActiveCN110372801BSimple processEasy to realize industrializationFermentationCentrifugationGranular starch

The invention discloses an enzymatic synchronous processing method for single-grain Gorgon fruit raw starch and related products. Using Gorgon fruit seed kernels as raw materials, aiming at the characteristics of Gorgon fruit starch particles such as fine grain size, aggregation of aggregates, intertwining of protein and starch granules, etc., the method uses protease at low temperature Hydrolyze the protein to separate the original aggregated Gorgon starch granules, and then combine the variable speed repeated centrifugation to separate the single-granule Gorgon starch from protein and Gorgon coarse powder, and finally obtain high-purity single-grain Gorgon starch and instant Gorgon There are two products of protein powder and gorgon powder. By adopting this technology, single-grain gorgon starch with a purity of more than 90% can be obtained, and the starch yield is more than 60%. At the same time, instant gorgon protein powder and a small amount of gorgon coarse powder can be obtained.

Owner:CHUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com