Preparation method of superfine zinc oxide powder

A technology of zinc oxide powder and starch, which is applied in the field of preparation of ultrafine zinc oxide powder, can solve problems such as inconvenient operation, compression feeding, retention, etc., and achieves the effects of simple preparation method, less impurities in the product, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

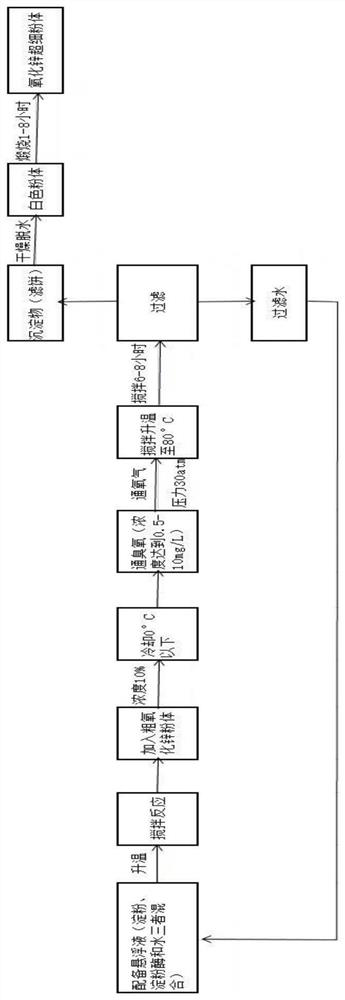

[0028] The invention discloses a preparation method of superfine zinc oxide powder, which comprises the following steps: the first step is to prepare a suspension, and the composition of the suspension is 5-10% of starch, 0.2-0.8% of amylase, and the rest is water; in the second step, put the suspension prepared in the first step into an autoclave and heat it up to 60-80°C, and then stir for 20-50 minutes; in the third step, add crude oil to the autoclave in the second step Granular zinc oxide powder 5-15%, make the concentration reach 10%, and then cool down to below 0°C, the fourth step, pass ozone into the suspension in the autoclave through the ozone generator, and wait until the ozone concentration reaches 0.5-10mg / L, then feed oxygen into it to make the pressure reach 30atm, close the valve, then stir slowly until the temperature of the autoclave reaches 80°C, and stir again for 6-8 hours; the fifth step, after the fourth step stirring reaction is completed , filter the...

Embodiment 2

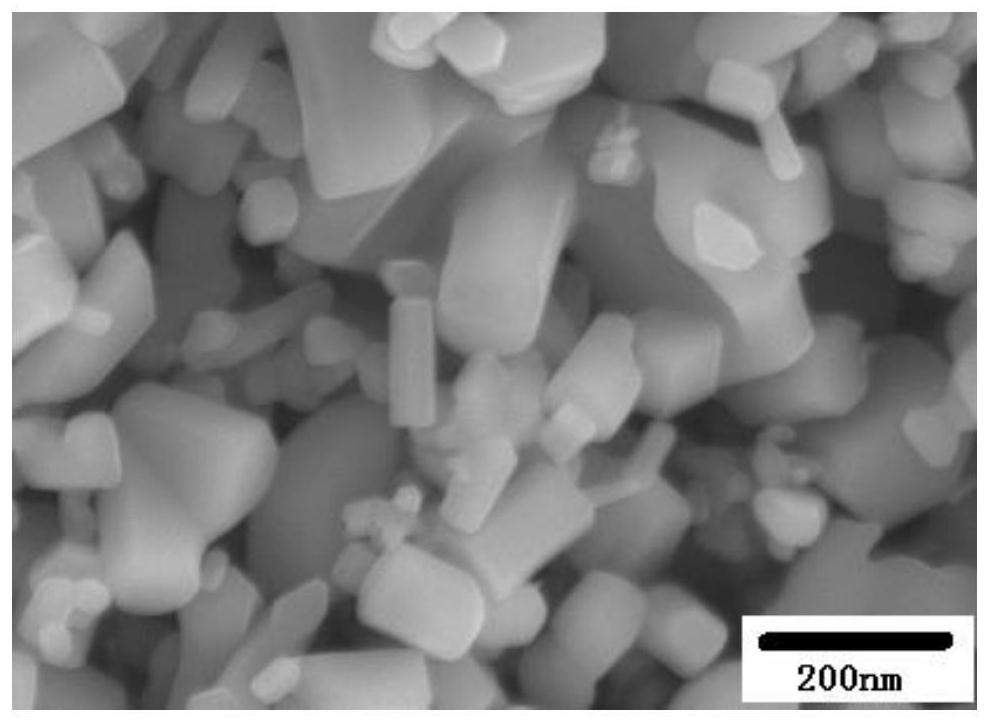

[0030] The invention discloses a preparation method of ultrafine zinc oxide powder, which comprises the following steps: the first step is to prepare a suspension, and the composition of the suspension is 5% of starch, 0.2% of amylase and the rest is water; the second The first step is to put the suspension prepared in the first step into an autoclave and heat it up to 60°C, and then stir for 20 minutes; the third step is to add 5% of coarse particle zinc oxide powder to the autoclave in the second step to make The concentration reaches 10%, and then it is cooled to below 0°C. In the fourth step, ozone is introduced into the suspension in the autoclave through an ozone generator. After the ozone concentration reaches 2.5mg / L, oxygen is introduced into it to make The pressure reaches 30atm, close the valve, then stir slowly until the temperature of the autoclave reaches 80°C, and stir again for 6 hours; in the fifth step, after the stirring reaction in the fourth step is complet...

Embodiment 3

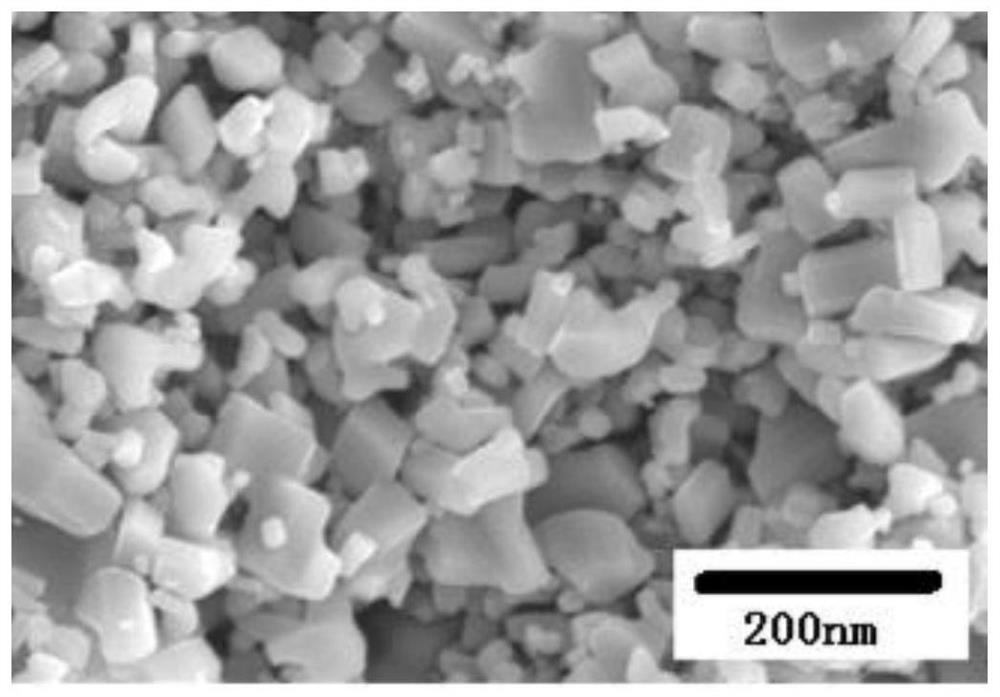

[0032] The invention discloses a preparation method of ultrafine zinc oxide powder, which comprises the following steps: the first step is to prepare a suspension, and the composition of the suspension is 10% of starch, 0.8% of amylase and the rest is water; the second The first step is to put the suspension prepared in the first step into an autoclave and heat it up to 80°C, and then stir for 50 minutes; the third step is to add 15% of coarse particle zinc oxide powder to the autoclave in the second step to make The concentration reaches 10%, and then it is cooled to below 0°C. In the fourth step, ozone is introduced into the suspension in the autoclave through an ozone generator. After the ozone concentration reaches 10mg / L, oxygen is introduced into it to make it When the pressure reaches 30atm, close the valve, then stir slowly until the temperature of the autoclave reaches 80°C, and stir again for 8 hours; in the fifth step, after the stirring reaction in the fourth step is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com