Easy open water soluble blister package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

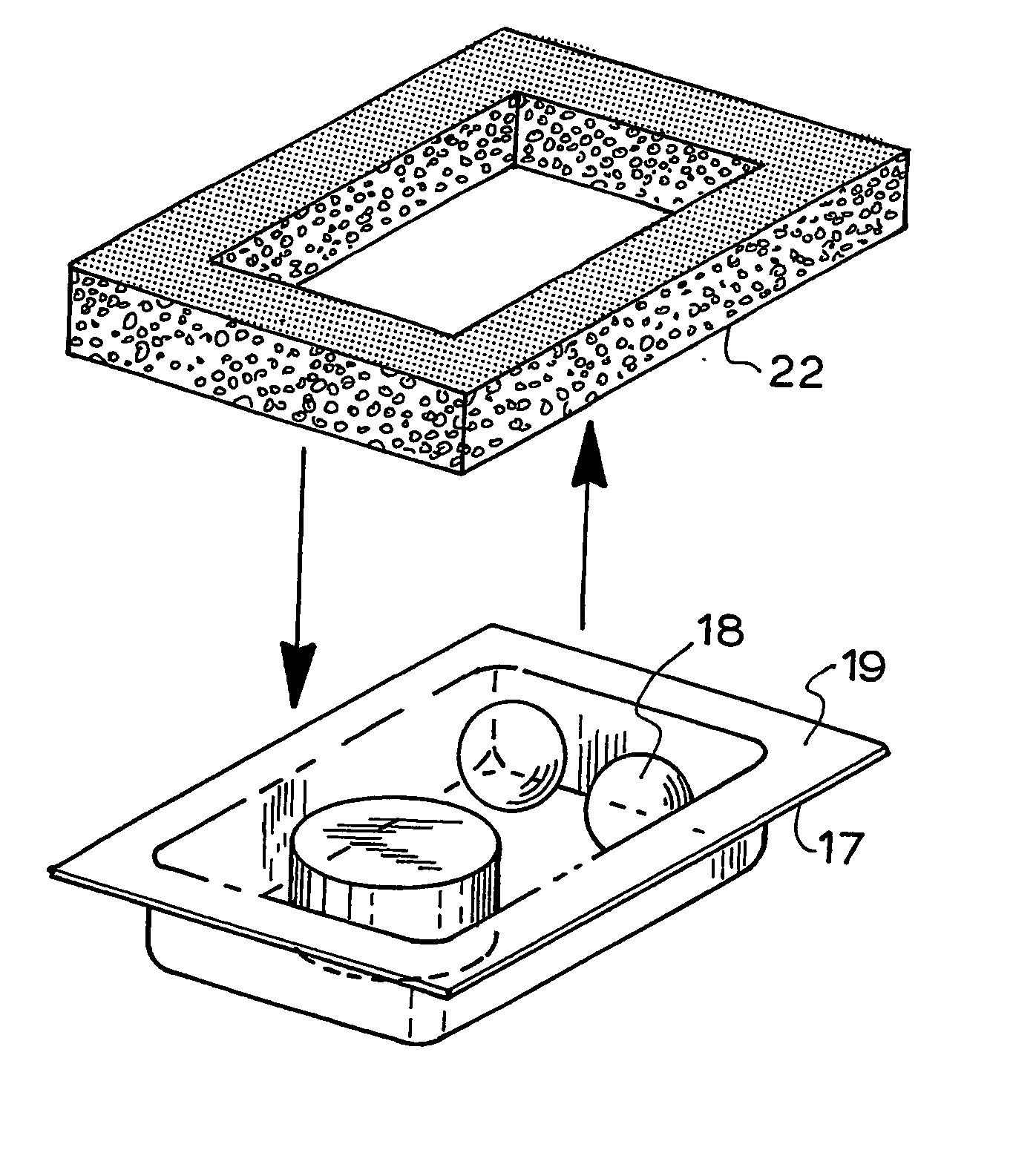

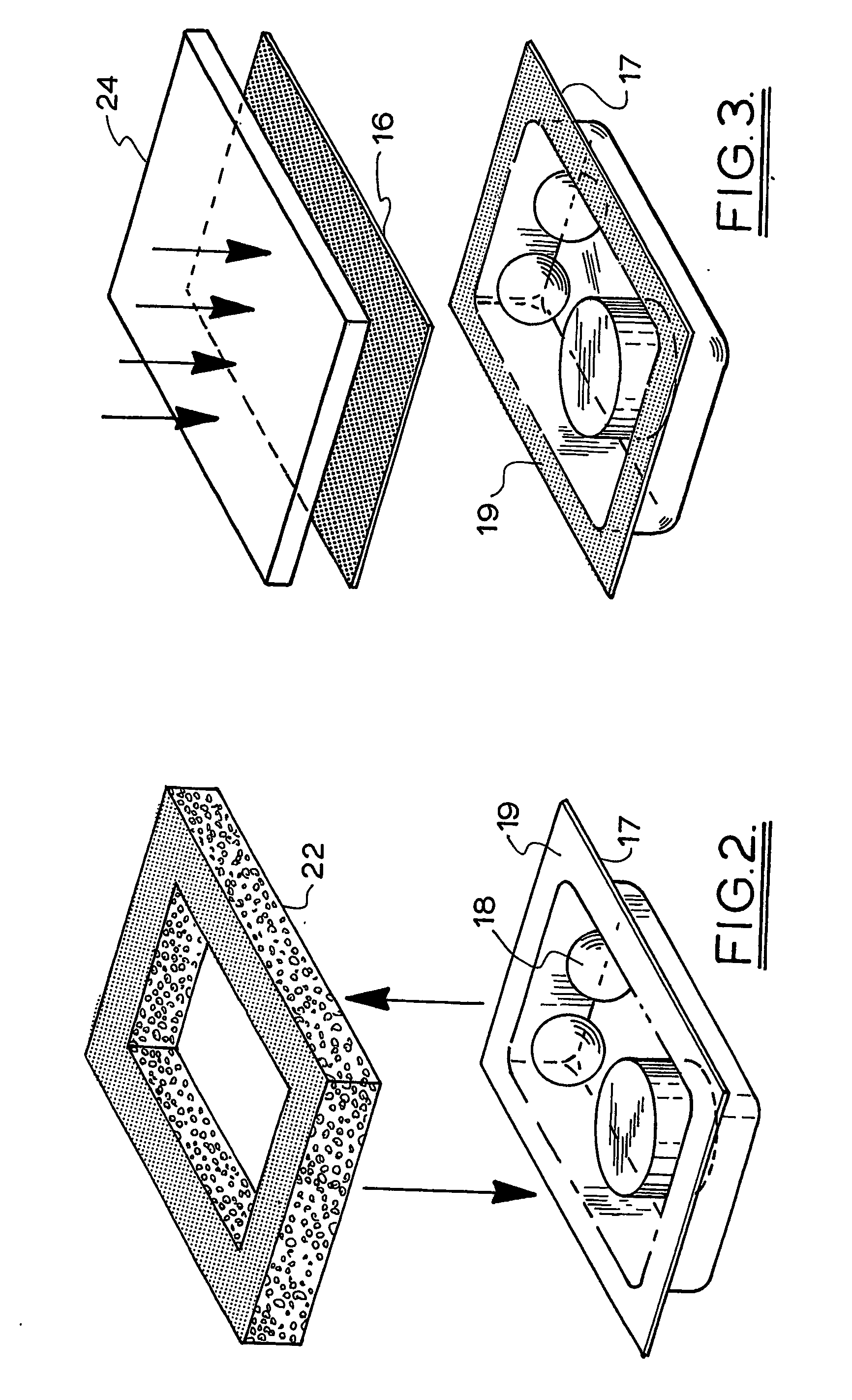

[0058] A blister pack of a toothbrush was formed using the polymer described above as a blister attached to a card packing.

[0059] A commercial toothbrush pack was used as a comparative measured example.

The force required to peel open the commercial product was2.415 NThe force required to peel open the blister pack of this3.180 NinventionThe force required to break the commercial product was0.226 KNThe force required to break the blister pack of this invention0.115 KNwasThe force required to break the blister pack of this invention0.001 KNafter wetting was

[0060] Effectively no force was required to open the blister pack of this invention once it was wet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com