A kind of enzymatic synchronous processing method of single granule gorgon starch and related products

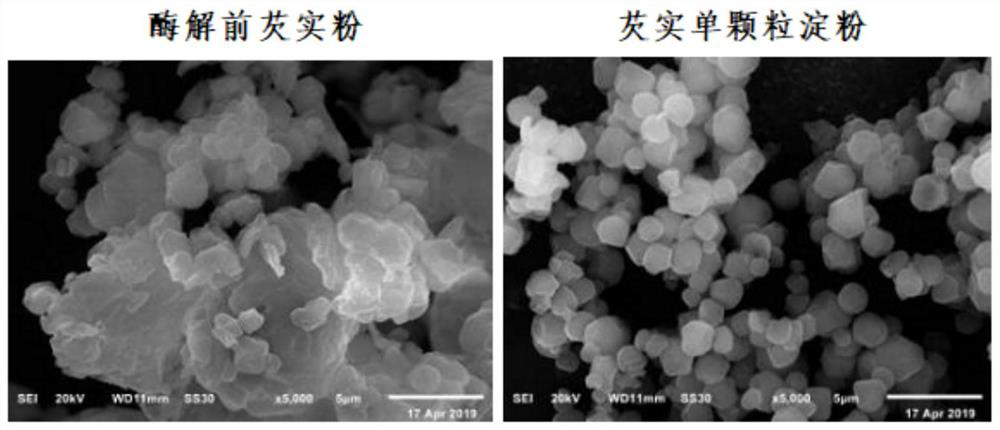

A related product and synchronous processing technology, applied in the food field, can solve the problem of no research reports on the extraction of single-grain Gorgon starch, and achieve the effect of narrow molecular size range, simple process, and fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

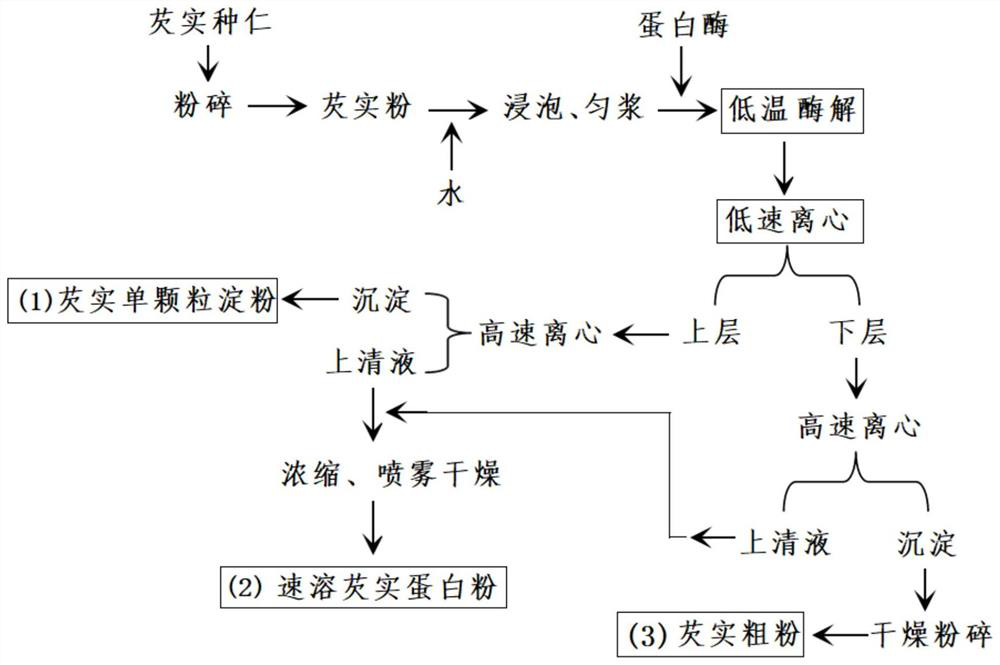

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, the low-temperature enzymatic processing of single-grain Gorgon starch and the synchronous processing method of instant Gorgon protein powder and Gorgon coarse powder are as follows:

[0037] 1. Gorgon seed kernels are crushed and homogenized. Weigh 100kg of Gorgon seed kernels, clean up impurities, crush them, and pass through a 100-200 mesh sieve to obtain Gorgon powder; add 10 times the volume of deionized water to the obtained Gorgon powder, soak for 2-4 hours, and homogenize at a high speed to obtain Gorgon powder slurry.

[0038] 2. Low temperature enzymatic hydrolysis. Add 1-1.5 kg of neutral protease to the Gorgon seed slurry, and enzymatically hydrolyze it below 50°C for 4 hours.

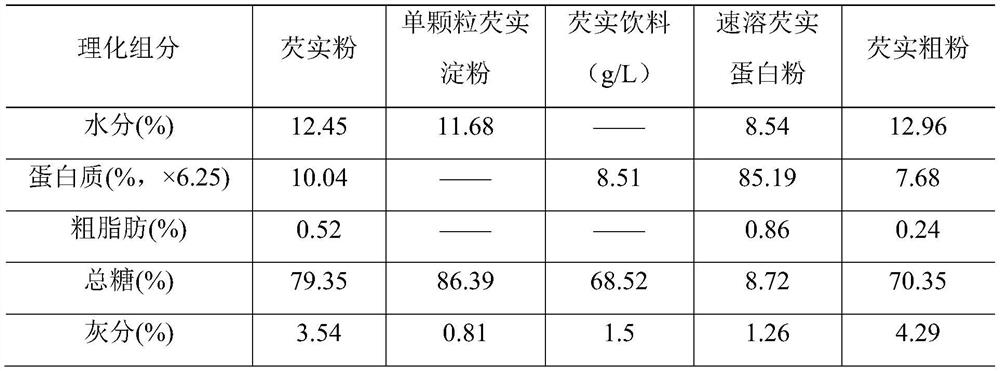

[0039] 3. Solid-liquid separation. After the enzymatic solution is separated at low speed, the upper layer solution is poured out, and then centrifuged at a high speed to obtain the supernatant (1). After concentration and drying, it becomes instant gorgon prot...

Embodiment 2

[0041] In this embodiment, the low-temperature enzymatic processing of single-grain gorgon starch and the synchronous processing method of gorgon protein beverage and gorgon starch are as follows:

[0042] 1. Gorgon seed kernels are crushed and homogenized. Weigh 100kg of Gorgon seed kernels, clean up impurities, crush them, and pass through a 100-200 mesh sieve to obtain Gorgon powder; add 12 times the volume of deionized water to the obtained Gorgon powder, soak for 2-4 hours, and homogenize at a high speed to obtain Gorgon powder slurry.

[0043] 2. Low temperature enzymatic hydrolysis. Add 1-1.5 kg of neutral protease to the Gorgon seed slurry, and enzymatically hydrolyze it below 50°C for 4 hours.

[0044] 3. Solid-liquid separation. Separation of the enzymolysis solution at low speed, pouring out the upper layer solution, and then performing high-speed centrifugation to obtain the supernatant (1), the precipitate is single-grain Gorgon starch, with a yield of 65-70%; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com