Photo-thermal stable vitamin microcapsule powder and preparation method thereof

A vitamin and microcapsule powder technology, applied in the field of vitamin microcapsule powder and its preparation, can solve the problems of less than 30% retention rate of vitamin K1, limited protection of vitamin loss, less involved in vitamin loss, etc., and achieves improved stability and application. Scope, excellent water solubility, good flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

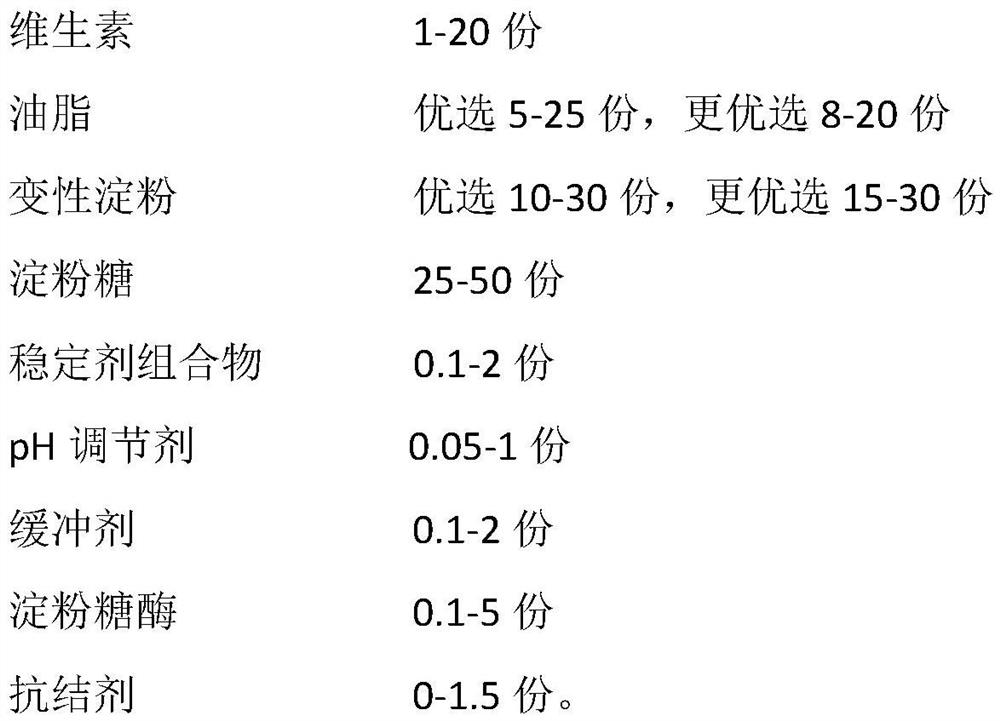

Method used

Image

Examples

Embodiment 1

[0039] Under the condition of avoiding light and passing nitrogen, weigh 150g MCT into a 500ml beaker, keep the temperature at 42°C, add 1.0g astaxanthin and 120g vitamin D3, and stir until completely dissolved. This is the Phase A solution.

[0040] Weigh 300g of deionized water into a 1000ml beaker, keep the temperature at 42°C, add 250g of modified starch, stir and disperse evenly, add phase A solution, stir and emulsify to obtain primary emulsion.

[0041] Weigh 500g of deionized water into a 1000ml beaker, control the temperature at 60°C, add 460g of maltodextrin to it, stir and disperse evenly, adjust the pH of the emulsion to 4.7 with 2.0g of phosphoric acid, add 5g of glucose glucoamylase to it, and enzymatically hydrolyze it. The DE value of the obtained solution was 78%, and then boiled in a water bath for 20 minutes to inactivate the enzyme, the enzymolysis solution was cooled to 42°C, 2.2g of potassium dihydrogen phosphate was added, and stirred to dissolve. Add it ...

Embodiment 2

[0045] Under the condition of avoiding light and nitrogen, weigh 750g sunflower oil into a 2000ml beaker, keep the temperature at 40°C, add 8.0g astaxanthin and 500g vitamin K1, stir until completely dissolved, this is the A phase solution.

[0046] Weigh 2000g of deionized water into a 5000ml beaker, keep the temperature at 40°C, add 1400g of modified starch, stir and disperse evenly, add phase A solution, stir and emulsify to obtain primary emulsion.

[0047] Weigh 2500g of deionized water into a 2000ml beaker, keep the water temperature at 58°C, add 2260g of maltooligosaccharide to it, stir and disperse evenly, adjust the pH of the emulsion to 4.5 with 5.0g of hydrochloric acid, add 40g of isoamylase to it for enzymatic hydrolysis, The DE value of the obtained solution was 70%, and then boiled in a water bath for 20 minutes to inactivate the enzyme, the enzymolysis solution was cooled to 40°C, 5.5g of disodium hydrogen phosphate was added, and stirred to dissolve. Add it in...

Embodiment 3

[0051] Under the protection of light and nitrogen, weigh 260g soybean oil into a 500ml beaker, keep the temperature at 41°C, add 2.4g astaxanthin and 300g vitamin A palmitate, stir until completely dissolved, this is phase A.

[0052] Weigh 600g of deionized water into a 2000ml beaker, keep the water temperature at 40°C, add 440g of modified starch, stir and disperse evenly, add phase A solution, stir and emulsify to obtain primary emulsion.

[0053] Weigh 1000g of deionized water into a 1500ml beaker, keep the water temperature at 56°C, add 940g of resistant dextrin to it, stir and disperse evenly, adjust the pH of the emulsion to 5.1 with 2.0g of citric acid, add 16g of pullulanase, and enzymolyze , the DE value of the solution was 79%, and then the enzyme was inactivated in a boiling water bath for 20 minutes, the temperature of the enzymolysis solution was lowered to 41° C., 8.2 g of potassium citrate was added, and stirred to dissolve. Add it into the primary emulsion, em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com