Polyurethane elastomer preparation method using starch liquefaction products

A technology of polyurethane elastomer and polyurethane elasticity, which is applied in the field of polyurethane elastomer preparation, can solve problems such as soaring prices and increased cost of polyether polyols, and achieve the effects of high hardness, strong water resistance, and reduced dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

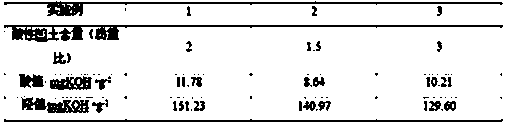

[0021] Example 1: Liquefaction of starch

[0022] In a 250 mL three-necked flask, add 30 g of liquefaction agent and 0.7 g of acidic attapulgite catalyst, start the agitator, raise the temperature to 150 ° C, add 5 g of starch, and stop the reaction after 120 min of reaction, and measure the hydroxyl value of the liquefied product and acid value; wherein, the liquefaction agent is composed of 20 g polyethylene glycol 400 (PEG#400) and 10 g glycerol.

Embodiment 2

[0023] Embodiment 2: with embodiment 1, wherein, the acidic attapulgite catalyst accounts for 1.5% of liquefier and starch gross weight.

Embodiment 3

[0024] Embodiment 3: same as embodiment 1, wherein, acidic attapulgite catalyst accounts for 3% of liquefier and starch gross weight.

[0025] The performance index of embodiment 1-3 gained starch liquefaction product is as follows:

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com