Preparation method and application of oxidized-carboxymethylated amyloid cigarette humectant

A humectant for cigarettes and carboxymethylation technology, which is applied in the field of preparation of oxidized-carboxymethylated starchy humectants for cigarettes, can solve the problems of complicated preparation process, few sources of raw materials, high cost, etc. Extensive, reduce tobacco leaf consumption, improve the effect of processing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

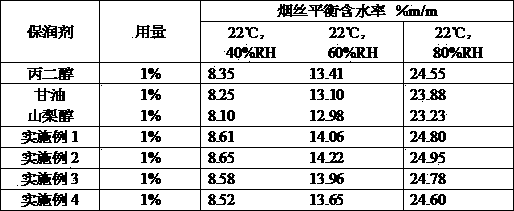

Examples

Embodiment 1

[0024] Example 1. Add 350g of waxy cornstarch to ethanol / water (V / V=70:30) solution to make 37% starch milk, add 35g of sodium hypochlorite within 1-2 hours, and react at 50°C for 6 hours. In addition, during the reaction process, 2% sodium hydroxide aqueous solution should be continuously added dropwise to stabilize the pH value at neutral. After the reaction is over, reduce the excess sodium hypochlorite with sodium sulfite, and finally dehydrate, wash, dry, pulverize and sieve. points to obtain oxidized starch. Add g of oxidized starch to ethanol / water (V / V=80:20) solution to make 37% starch milk, then add 36g of sodium hydroxide and 70g of sodium chloroacetate in sequence, and react at 45°C for 7 hours, Neutralize to neutral with concentrated hydrochloric acid, then dehydrate, wash, dry, pulverize and sieve in sequence to obtain oxidized-carboxymethylated starch. Dissolve oxidized-carboxymethylated starch in water to prepare a 40% solution, and add 0.2% preservative and ...

Embodiment 2

[0025] Example 2. Add 350g of waxy corn starch to ethanol / water (V / V=70:30) solution to make 37% starch milk, add 48g of potassium permanganate within 1-2 hours, and react at 50°C 8 hours. In addition, during the reaction process, 2% sodium hydroxide aqueous solution should be continuously added dropwise to stabilize the pH value at neutral. After the reaction, the excess potassium permanganate was reduced with sodium sulfite, and finally dehydration and washing were carried out respectively. , drying, pulverizing and sieving to obtain oxidized starch. Add oxidized starch to ethanol / water (V / V=80:20) solution to make 37% starch milk, then add 108g sodium hydroxide and 130g chloroacetic acid in turn, react at 45°C for 7 hours, and use concentrated The hydrochloric acid is neutralized to neutrality, and then dehydration, washing, drying, crushing and sieving are carried out in sequence to obtain oxidized-carboxymethylated starch. Dissolve oxidized-carboxymethylated starch in w...

Embodiment 3

[0026] Example 3. Add 350g waxy corn and rice starch to ethanol / water (V / V=70:30) solution to make 38% starch milk, add 73g sodium hypochlorite within 1-2 hours, and react at 53°C for 10 hours In addition, during the reaction process, 2% aqueous sodium hydroxide solution should be continuously added dropwise to stabilize the pH value at neutral. After the reaction is over, reduce the excess sodium hypochlorite with sodium sulfite, and finally dehydrate, wash, dry, pulverize and Sieve to obtain oxidized starch. Add oxidized starch to ethanol / water (V / V=80:20) solution to make 38% starch milk, then add 90g sodium hydroxide and 178g sodium chloroacetate in sequence, react at 45°C for 9 hours, use Concentrated hydrochloric acid is neutralized to neutral, followed by dehydration, washing, drying, crushing and sieving to obtain oxidized-carboxymethylated starch. Dissolve oxidized-carboxymethylated starch in water to prepare a 40% solution, and add 0.2% preservative and 0.2% defoam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com