Straw gasification furnace

A gasifier and straw technology, applied in the field of gasifier, can solve the problems of excessively burning straw and frequent feeding, and achieve the effects of good effect, resource saving and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

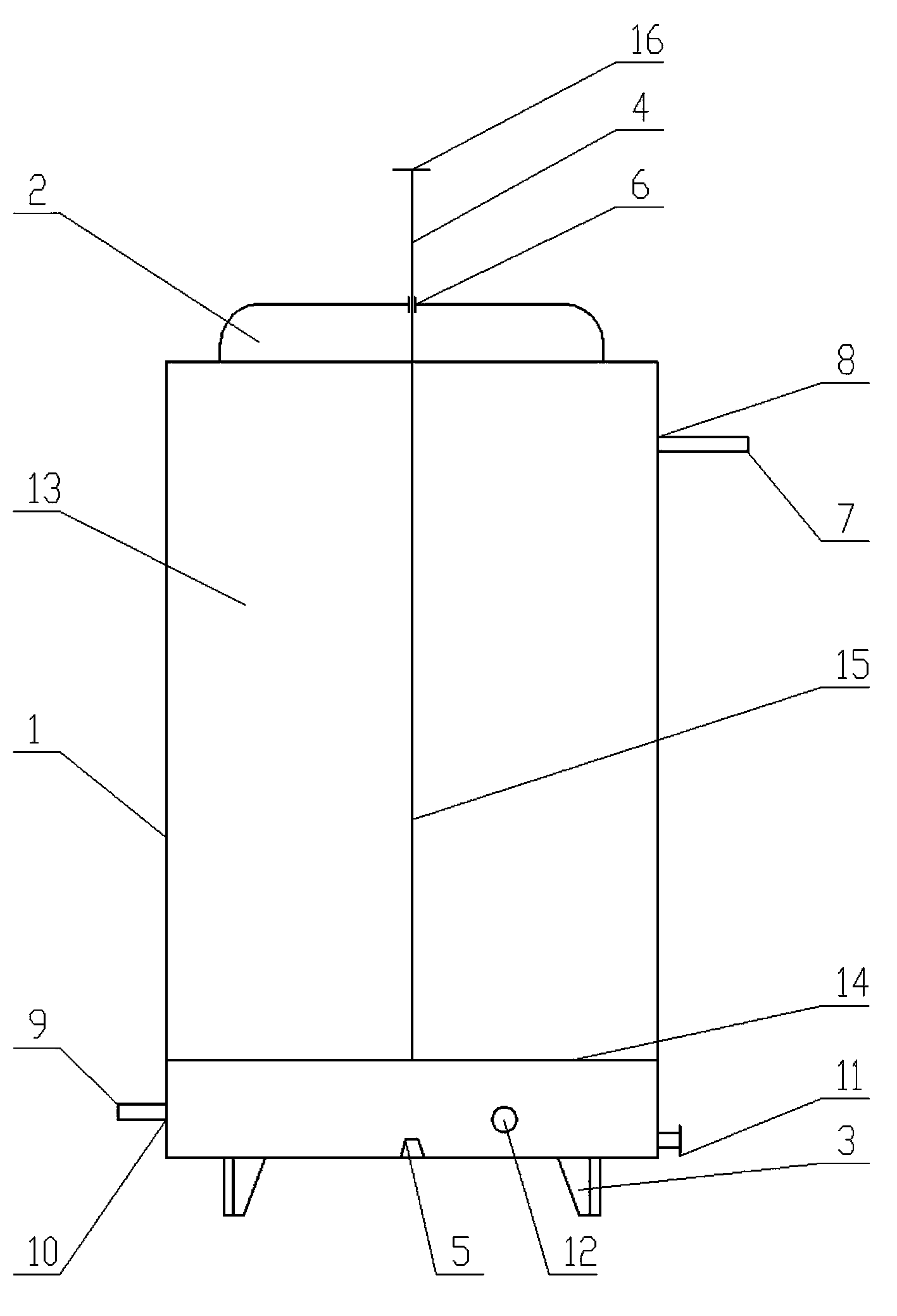

[0013] The structure of the straw gasifier is as follows: figure 1 As shown, the furnace body 1 is fixedly installed on the support 3 , and the furnace cover 2 is installed on the top of the furnace body 1 to form a gasification chamber 13 inside the furnace body 1 .

[0014] The bottom of the furnace body 1 is respectively provided with an ash outlet 11 and an ignition outlet 12, and the ash outlet 11 and the ignition outlet 12 can also be combined into one. An air inlet pipe 9 is connected to the bottom of the body of furnace 1, and a dust blocking filter screen 10 is arranged on the air inlet pipe 9. The upper part of the furnace body 1 is provided with a combustible gas passage 7, and a filter 8 is installed on the combustible gas passage 7.

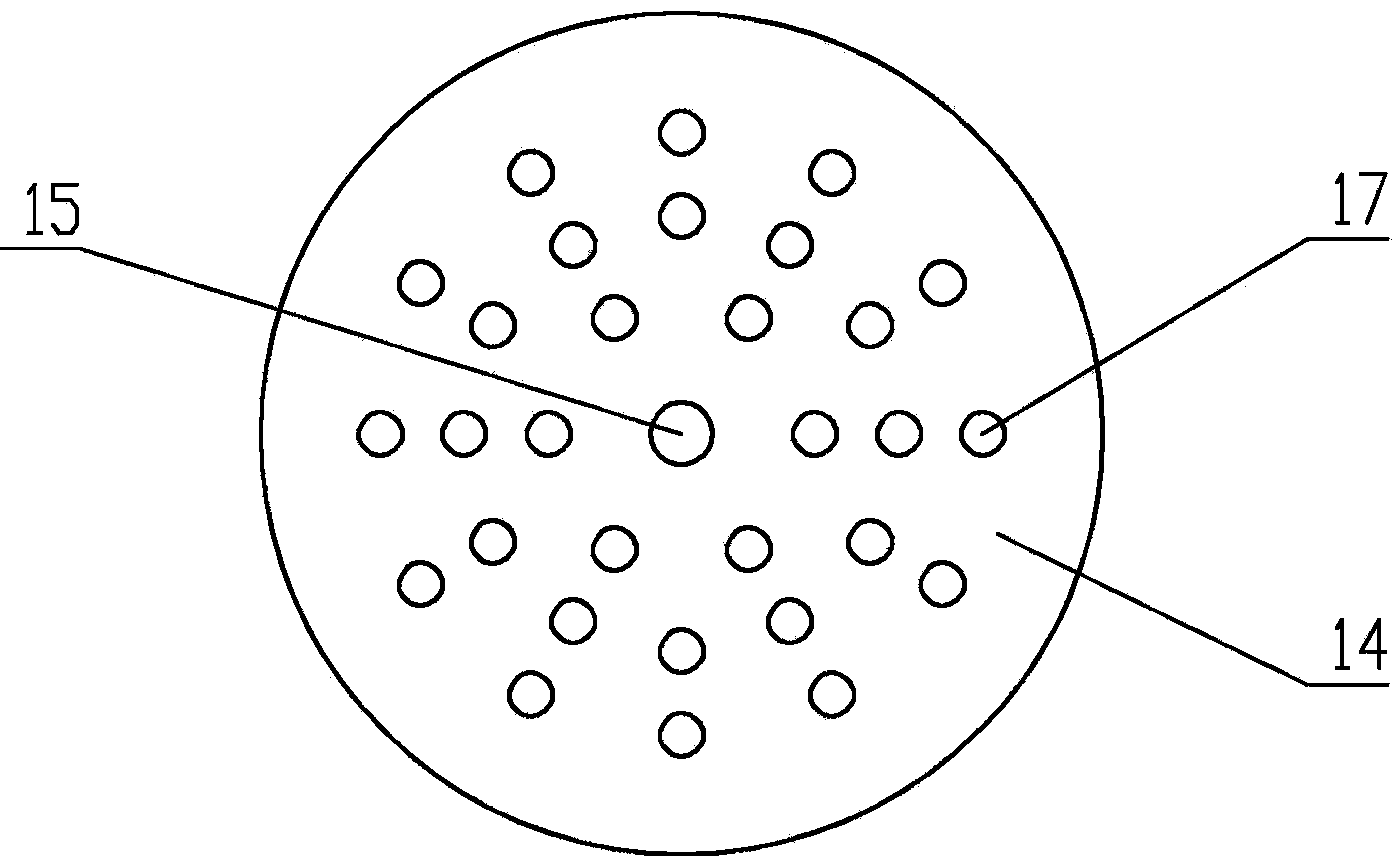

[0015] Compactor 4 is installed in the body of furnace 1, and its structure is as figure 2 As shown, it is composed of a compactor chassis 14 and a pull rod 15, the diameter of the compactor chassis 14 is slightly smaller than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com