Flexible drilling rod for radial horizontal well drilling

A flexible drill pipe and horizontal well technology, applied in drill pipe, drilling equipment, drill pipe, etc., can solve the problems of slow sliding and drilling speed of the hose, poor stability of the pipe string, and can not be completed at the same time, so as to achieve a simple and reliable structural design , The effect of large transmission torque and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

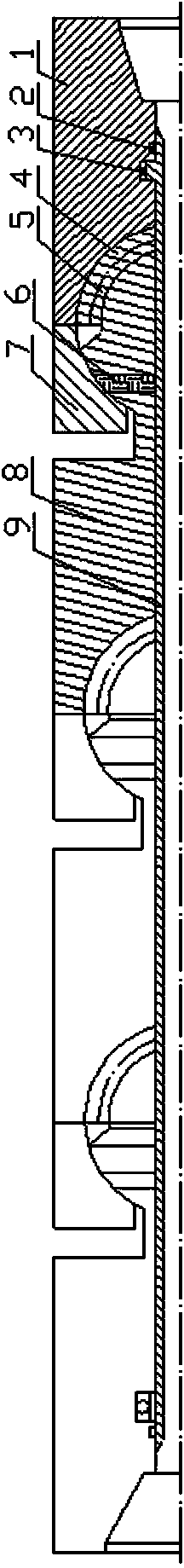

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] like figure 1 , a flexible drill pipe used for drilling radial and horizontal wells is formed by connecting multiple groups of improved ball-tooth cardan shafts. A high-pressure hose 9 is installed inside the flexible drill pipe, and the two ends of the high-pressure hose 9 are connected to the inner wall of the flexible drill pipe. The bearing 3 and the sealing ring 2 are installed between them, the inner button 4 meshes with the outer button 5, the ball cap 7 is used to lock the inner button 4, and the sealing ring 6 is installed between the ball cap 7 and the inner button 4, In each group of cardan shafts in the middle of the flexible drill rod except the joint, the outer button 5 is processed in the connecting shaft 8 and meshes with the next group of inner button 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com