Method for realizing drilling and hole sealing based on drill cuttings during uplink gas extraction

A gas extraction and hole sealing technology, which is used in gas discharge, mining equipment, earthwork drilling, etc., can solve the problems of low hole sealing efficiency and high hole sealing cost, and achieve low hole sealing cost, good sealing effect and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

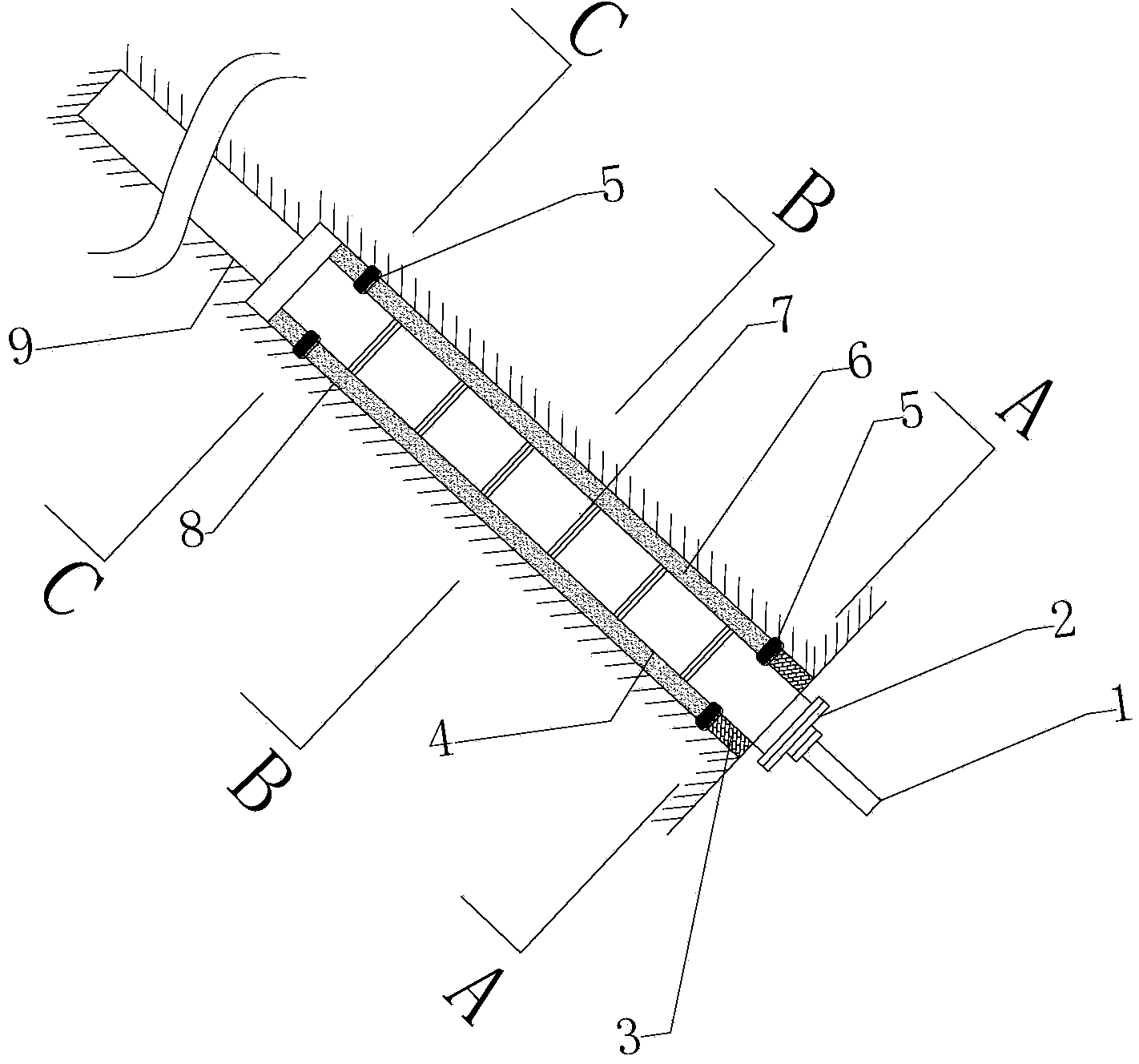

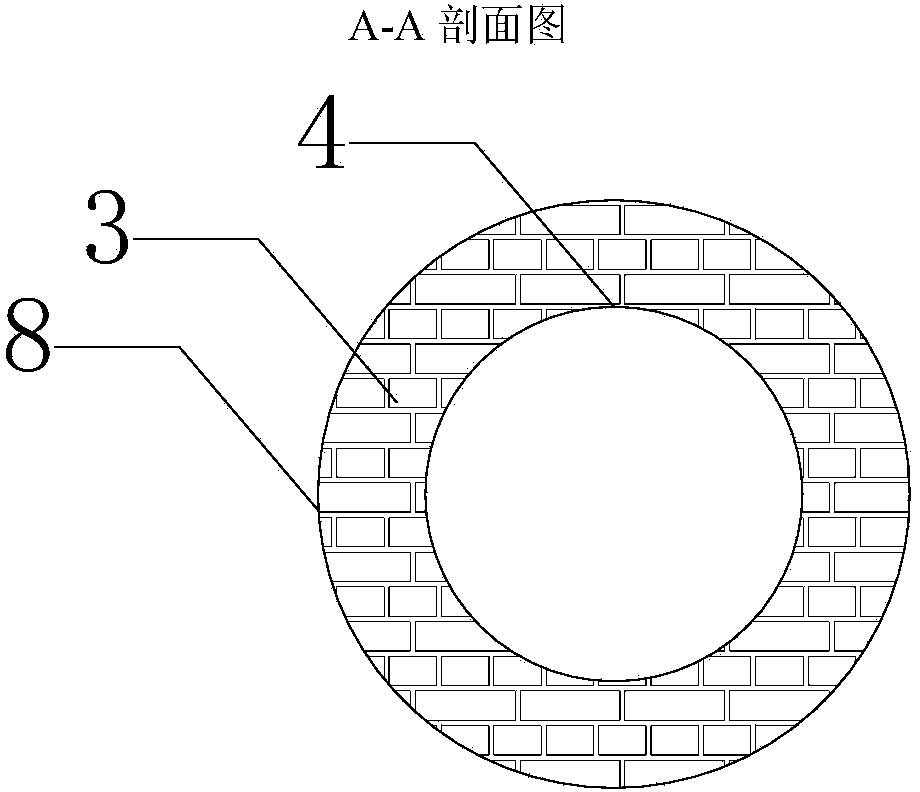

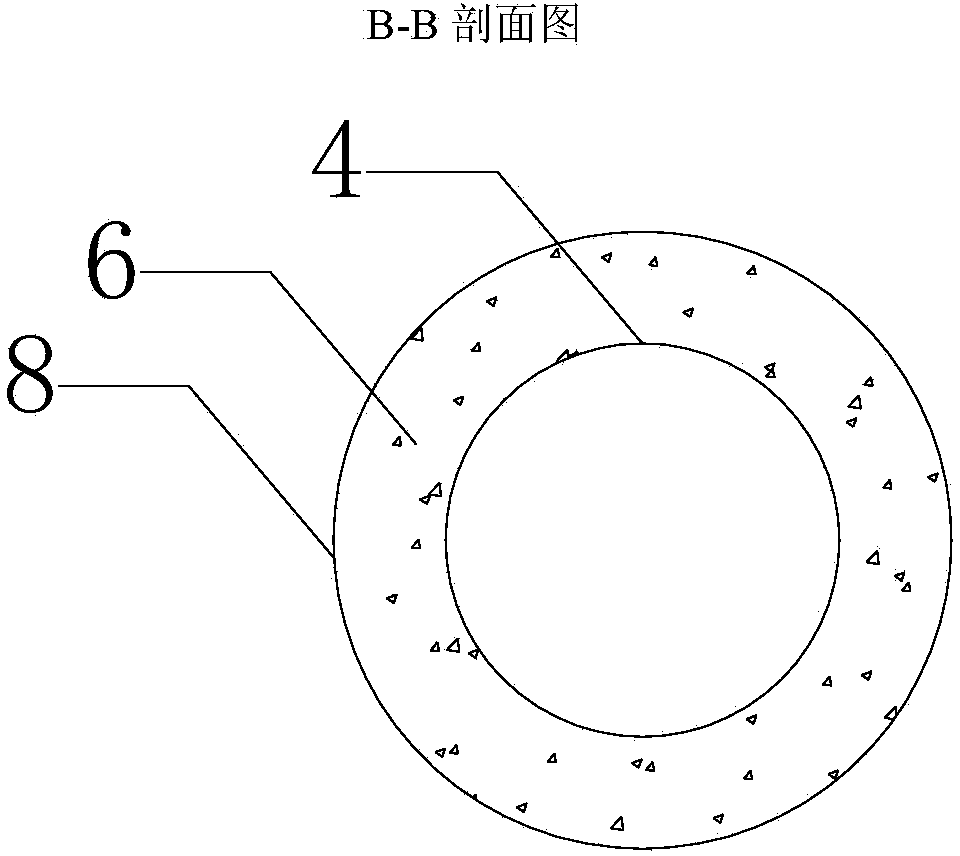

[0022] exist figure 1 Among them, the drilling cuttings sealing method for uplink gas drainage of the present invention includes a gas drainage pipe 1, a PVC casing 4, a fixing frame 5, and plugging between the outer end of the PVC casing 4 and the opening of the large borehole 8 Between polyurethane3. Described fixing frame 5 is made up of iron hoop 10, three iron frame feet 11 welded on iron hoop 10 in 120° distribution, and iron tripod 11 is perpendicular to iron hoop 10 surface. Firstly, a hole with a depth of 15m and a diameter of The large borehole 8; the large borehole 8 completes the retreat drill, and will be composed of multiple pieces with a total length of 14m and a diameter of The PVC bushing 4 is inserted into the large borehole 8, and a fixed frame 5 is respectively installed at the front and rear of the PVC casing 4 in the large bore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com