Exhaust-gas regeneration under rich conditions to improve fuel economy

An air and downstream technology, applied in the direction of exhaust gas recirculation, fuel injection control, adding non-fuel substances to fuel, etc., can solve problems such as ignorance of cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

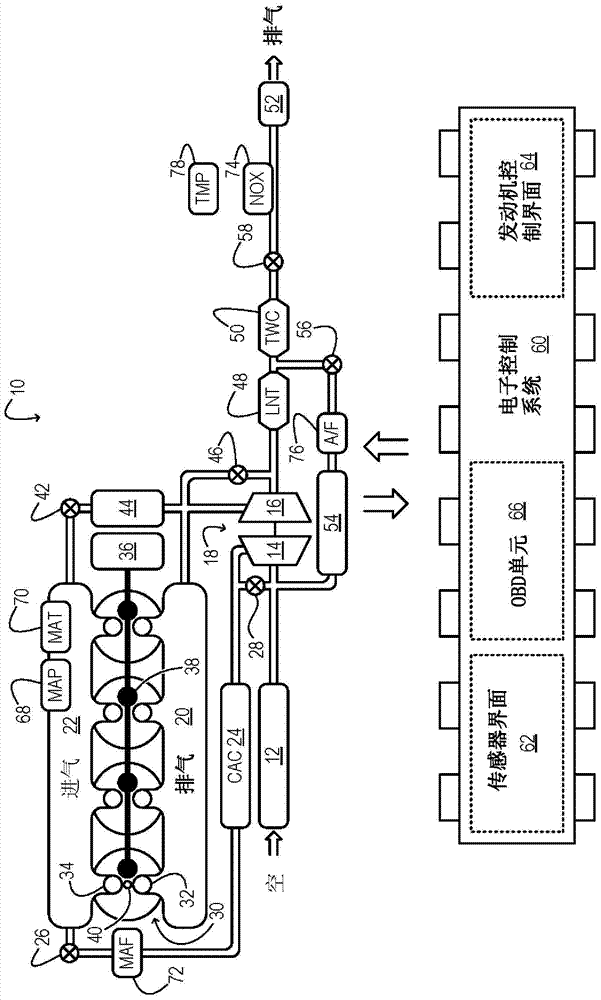

[0020] figure 1 Aspects of an example engine system 10 for a motor vehicle are shown schematically. In engine system 10 , fresh air first enters air cleaner 12 and flows to compressor 14 . The compressor may be any suitable intake compressor, such as a motor driven or drive shaft driven supercharger compressor. In engine system 10 , however, the compressor is mechanically coupled in turbocharger 18 to turbine 16 , which is driven by expanding engine exhaust from exhaust manifold 20 . In one embodiment, the compressor and turbine are coupled in a twin scroll turbocharger. In other embodiments, the turbocharger may be a variable geometry turbocharger (VGT), in which the geometry of the turbine actively changes as engine speed changes.

[0021] Compressor 14 is fluidly coupled to intake manifold 22 via charge air cooling (CAC) 24 and throttle valve 26 . Charge air from the compressor flows through the CAC and throttle valve to the intake manifold. In the illustrated embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com