Scroll heat radiation structure of scroll fluid machine and manufacturing method thereof

A technology of fluid machinery and heat dissipation structure, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, liquid fuel engines, etc., and can solve the problems of reducing heat dissipation effect and poor heat dissipation of metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. limit.

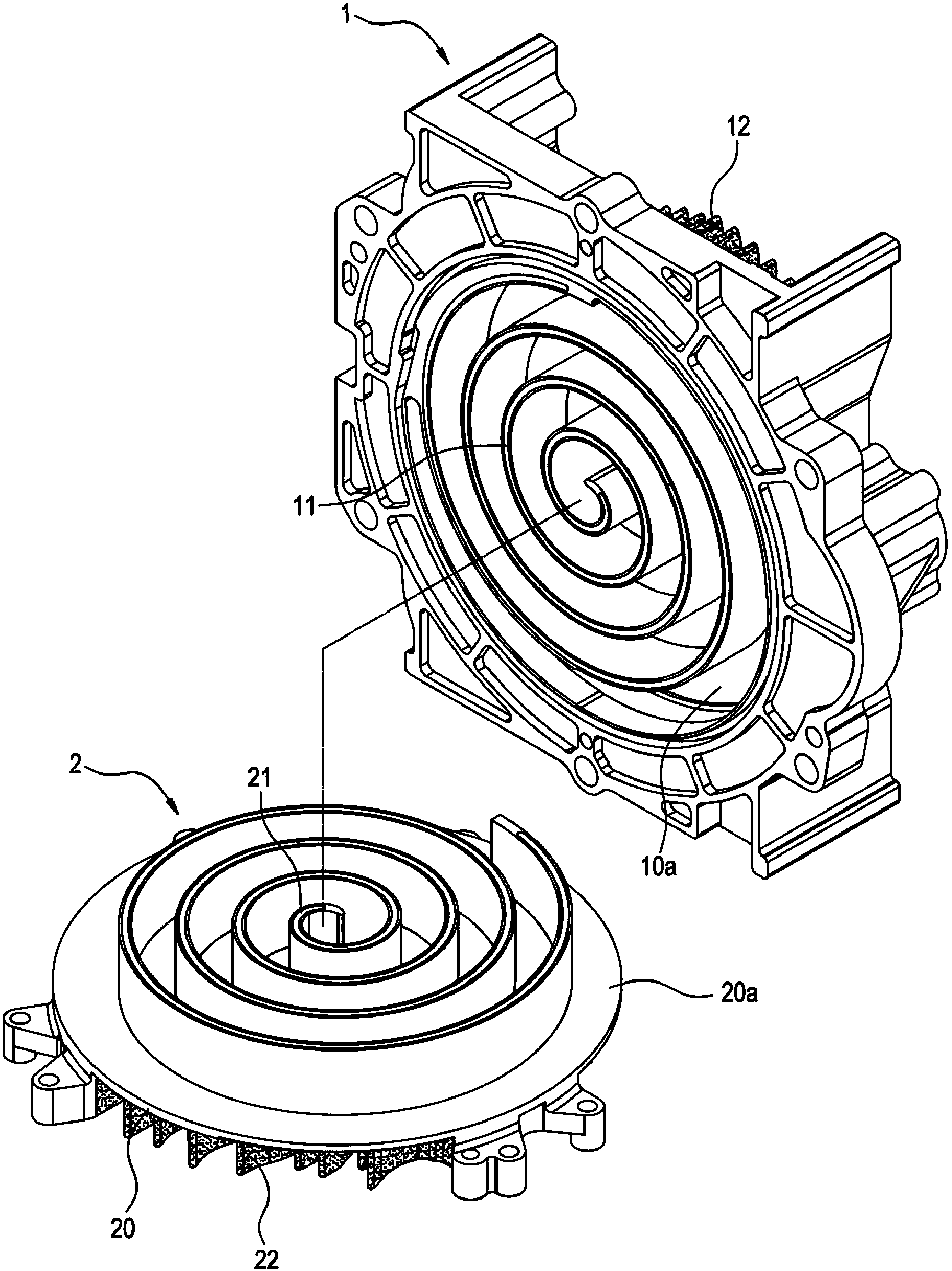

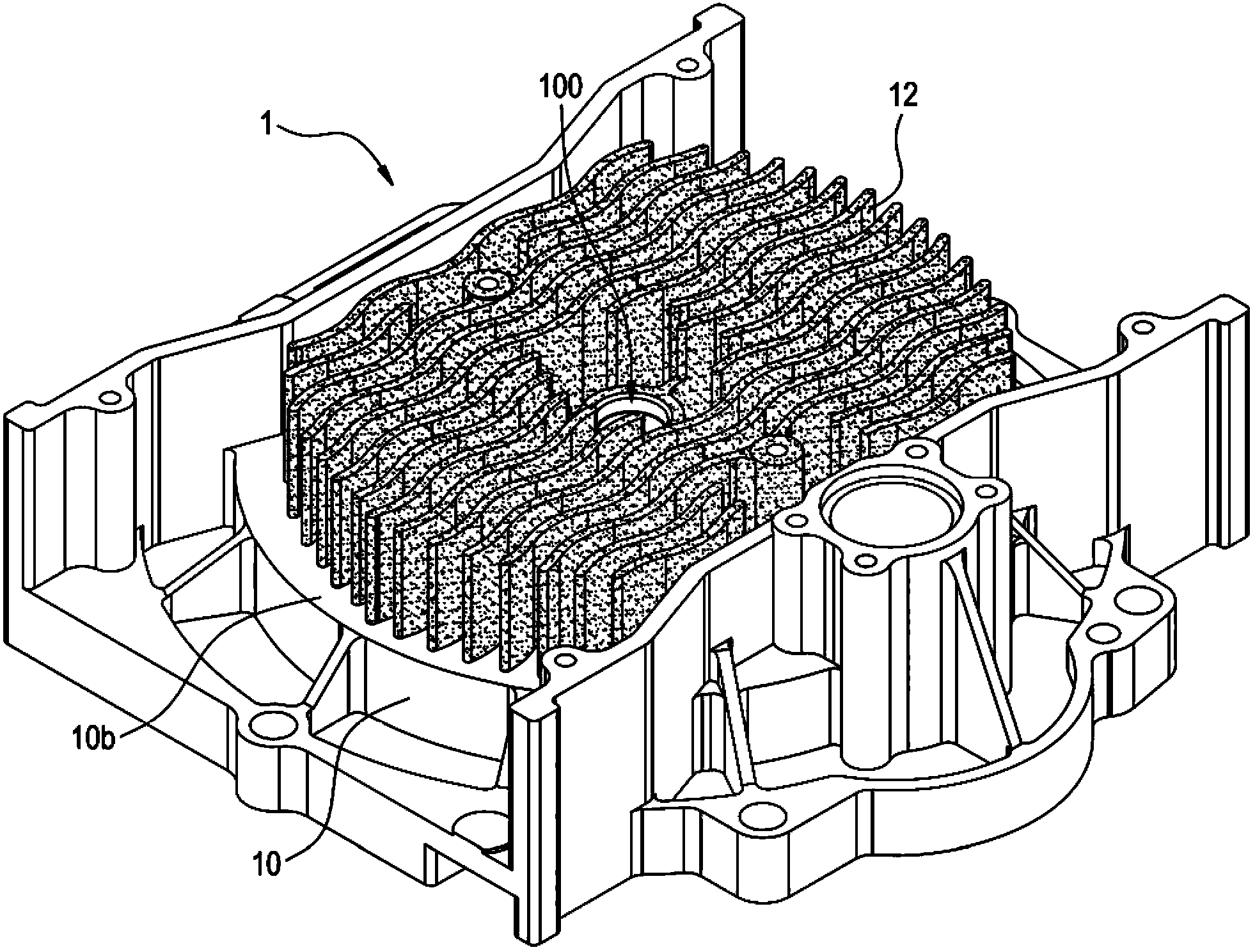

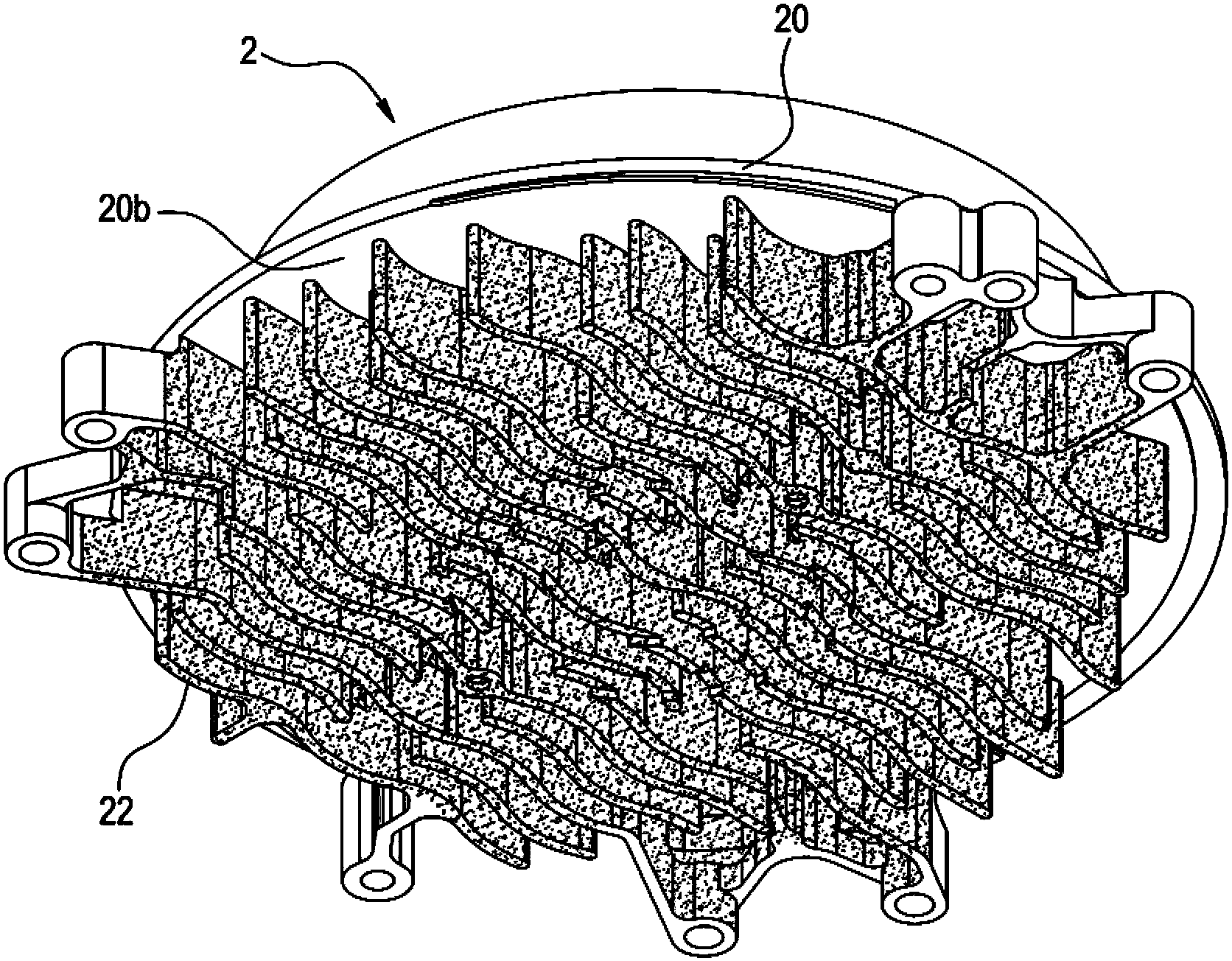

[0032] Please refer to figure 1 , figure 2 and image 3 , which are respectively the three-dimensional exploded view, the three-dimensional appearance view of the orbiting scroll and the three-dimensional appearance view of the fixed scroll of the present invention. The present invention provides a scroll heat dissipation structure of a scroll fluid machine and a manufacturing method thereof, comprising an orbiting scroll 1 and a fixed scroll 2 meshing with the orbiting scroll 1; wherein:

[0033] The orbiting scroll 1 can be supported in the scroll fluid machine by a transmission shaft (not shown in the figure), and can be driven by the eccentric operation of the transmission shaft. Please also refer to Figure 4 As shown, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com