Light-emitting diode (LED) curve-face light guide lamp

A technology of LED light bar and light guide lamp, which is applied in the direction of optics, light guide, light source, etc., can solve the problems of not being able to illuminate the surroundings uniformly, discomfort of the user's eyes, and high production cost, and achieve easy popularization and use, soft light, and low production cost. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

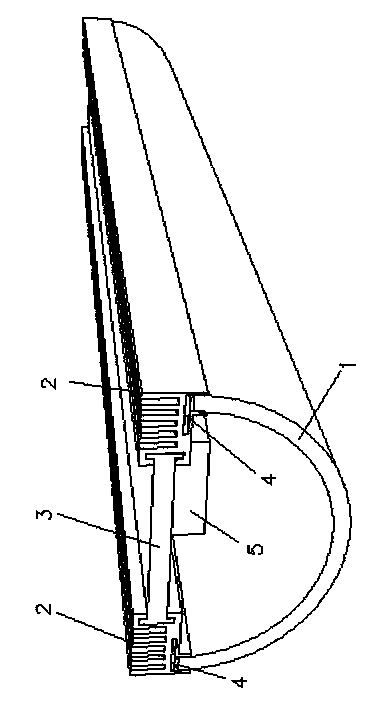

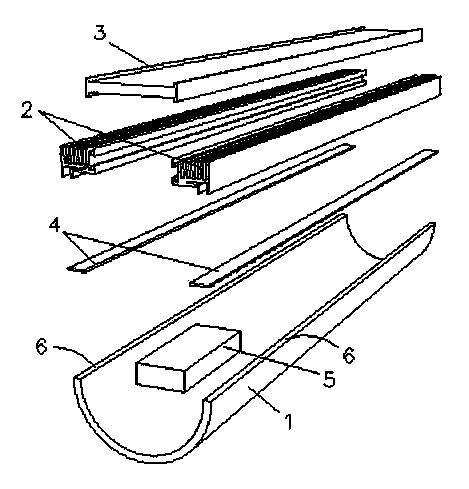

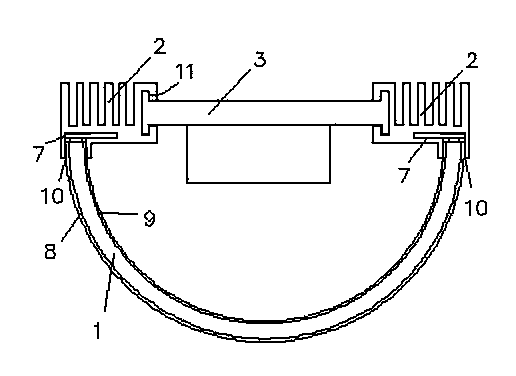

[0021] Such as Figure 1 to Figure 3 As shown, the present invention includes: a curved light guide plate 1, an LED light bar 4, and a heat dissipation bar 2. LED light bar 4, the light-emitting surface of the LED faces the cross-section, and is in contact with the longitudinal section. The LED is connected to the aluminum substrate. Contacting and connecting with the heat sink; said longitudinal section 6 means that the extended surface of the section passes through the axis line of the curved light guide plate, and coincides with the axis line, and the inner wall surface of the curved light guide plate is provided with reflective points and reflective layers 9, A light-scattering layer 8 is provided on the outer wall surface of the curved light guide plate, and the reflective layer and the light-scattering layer are in contact with the curved light guide plate. The curved light guide plate is a transparent tube with smooth inner and outer walls. The reflective layer 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com