Hot wind distributor

A hot air distributor and air intake technology, which is applied in lighting and heating equipment, dryers, drying, etc., can solve problems such as unevenness, loss of wind at the tail of the volute and straight air intake, etc., to reduce wind pressure loss , Reduce the effect of tail loss and low energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

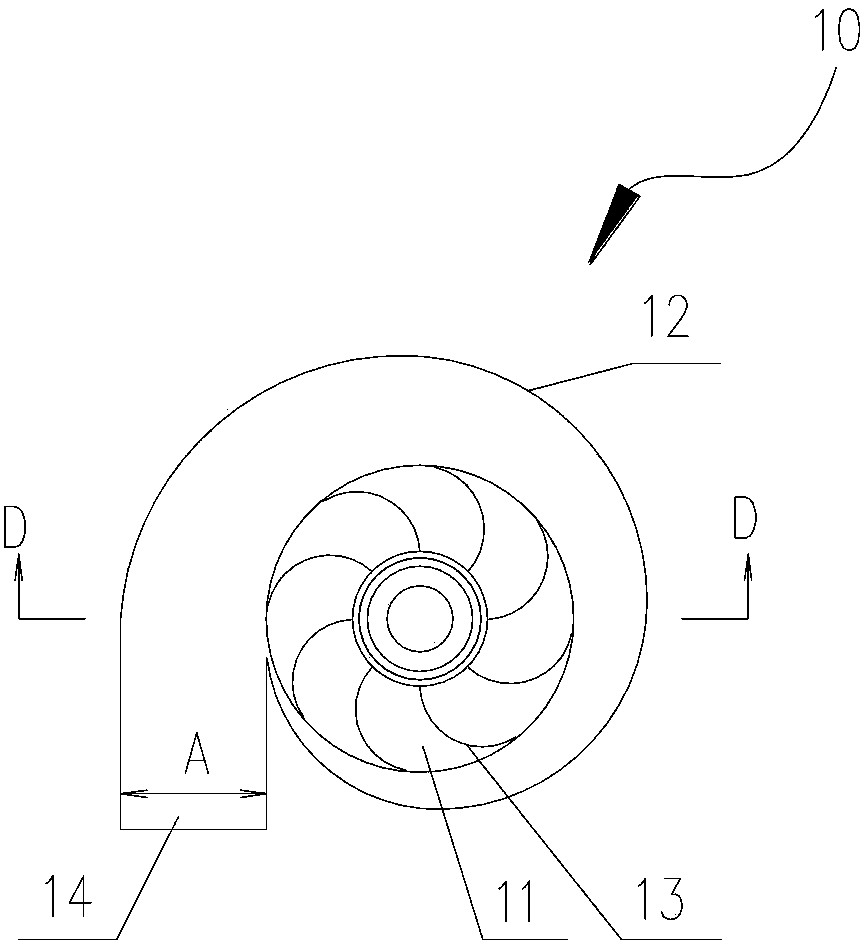

[0046] First, according to actual working conditions, the radius of the first bottom plate 21 and the second bottom plate 22 is determined to be 365 mm, and the thickness C of the air guiding device 11 is selected to be 130 mm. The radius of the deflector 13 is half of the radius of the first bottom plate 21 , that is, 182.5mm. The number of deflectors 13 is selected as eight.

[0047] Then, according to actual working conditions, the thickness B of the volute 12 is initially determined to be 200mm, B:C=1:1.54, which is within the range of 1:1-1:5. Select the air inlet velocity U as 8m / s, and the gas volume flow rate V as 0.566m 3 / s, thus the width A of the air inlet 14 is calculated to be 350mm. B:A=1:1.75, within the range of 1:1-1:2.

[0048] Finally, an approximate Archimedes spiral is made according to the four-line involute spiral drawing method to obtain the shape of the circumferential side wall of the volute 12 .

[0049] It is found in actual use that the hot ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com