Off-axis alignment system and alignment method

An alignment system and off-axis technology, applied in the off-axis alignment system and the field of alignment, can solve the problems of large defocusing effect, high requirements for coherence of illumination beams, and difficult implementation, etc., and achieves simple optical path structure, Eliminates spatial coherence requirements, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

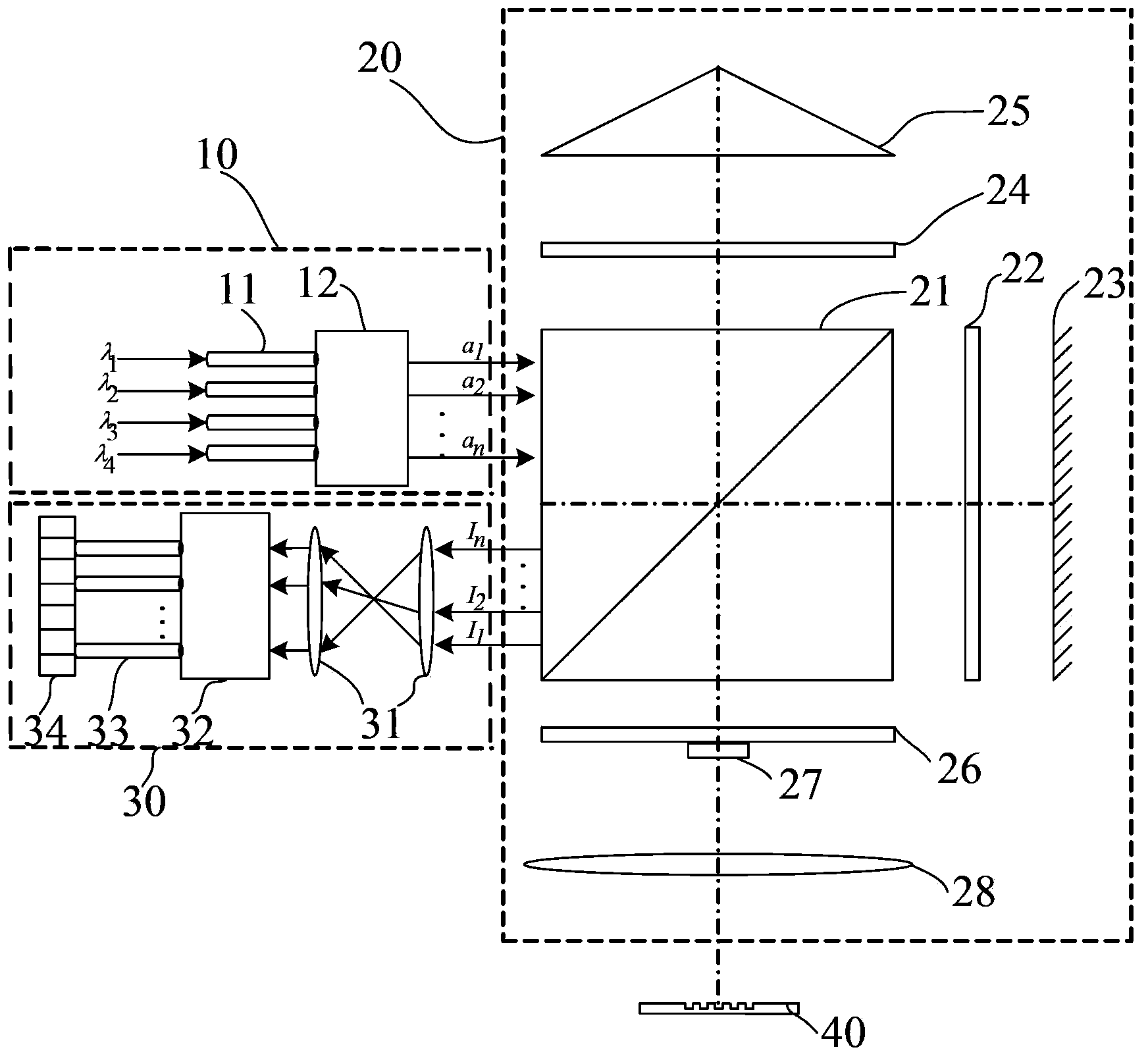

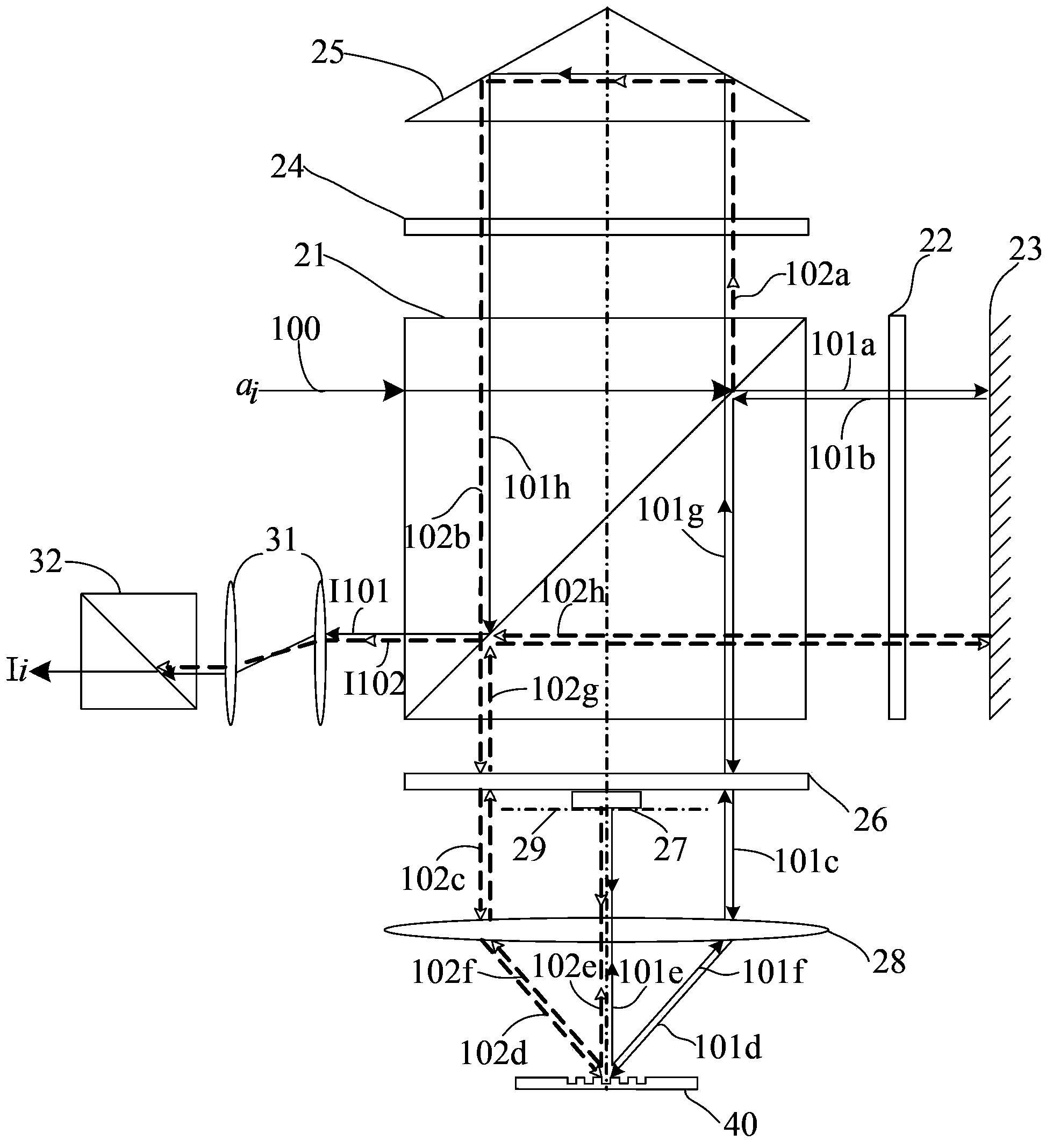

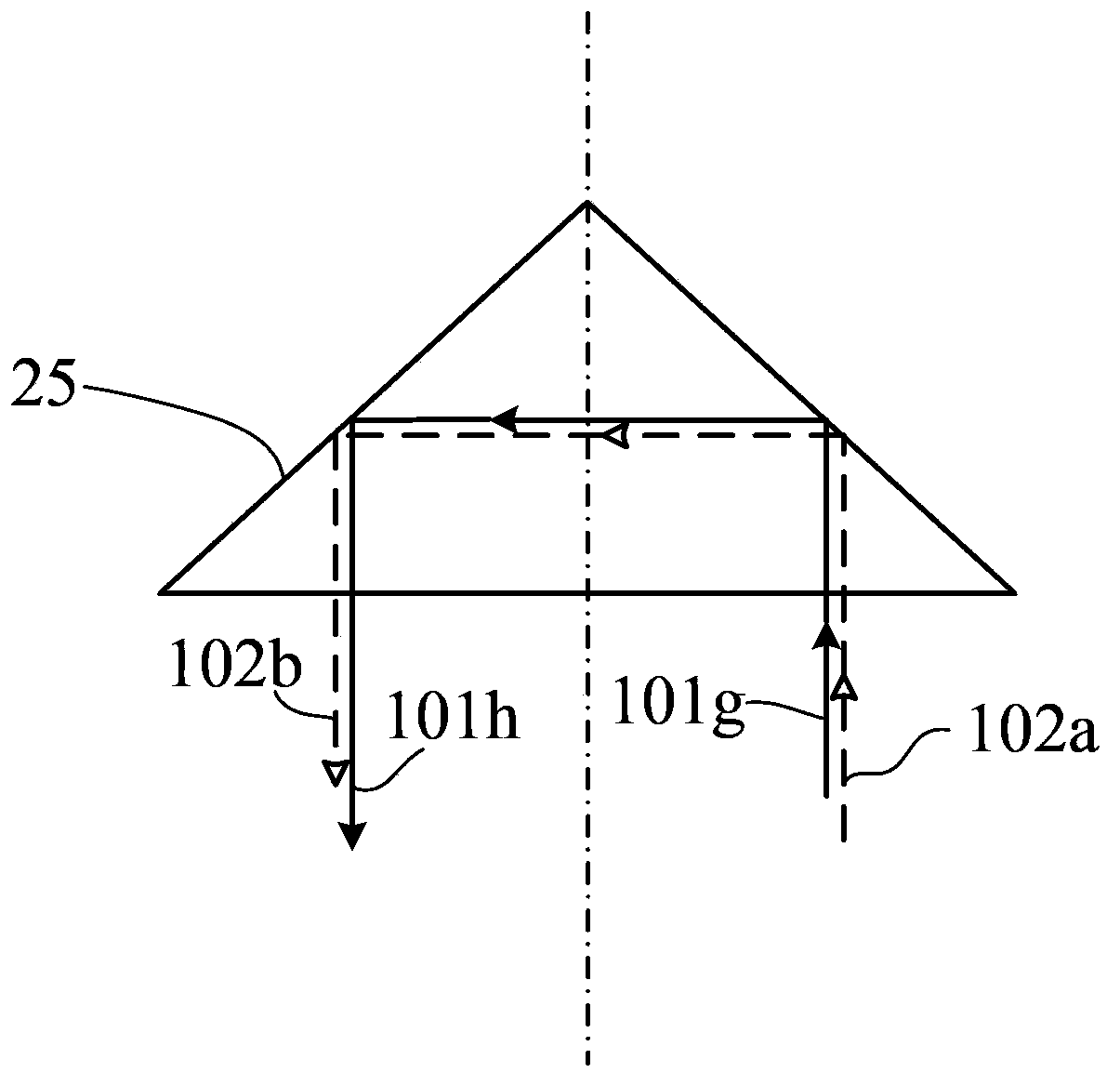

[0041] The off-axis alignment system provided by the present invention, such as figure 1 As shown, according to the beam propagation path, it includes an illumination module 10, an interference module 20, and a detection module 30. The illumination module 10 and the detection module 30 are located on the same side of the interference module 20. The illumination module 10 includes a light source (in the figure) (Not shown), the multi-wavelength incident fiber 11 and the beam splitting element 12. Preferably, the light source is a laser, because the laser has high brightness and good directivity. In the first embodiment, the light source is a single-frequency laser, which emits illumination The light beam is linearly polarized light with a single frequency. Preferably, the illumination module 10 further includes a shutter (not shown in the figure), an optical isolator (not shown in the figure) and a phase modulator (not shown in the figure) The shutter is used to block the illumin...

Embodiment 2

[0080] The difference between this embodiment and Embodiment 1 is that the light source adopts a dual-frequency laser, and the beam splitter 52 is a laser frequency splitter. Preferably, the laser frequency splitter is an electro-optic modulator or an acousto-optic modulator.

[0081] The off-axis alignment system provided by the present invention, such as Figure 13 As shown, it includes an illumination module 50, an interference module 60, and a detection module 70. The illumination module 50 and the detection module 70 are located on the same side of the interference module 60. The illumination module 50 includes a light source (not shown in the figure), The multi-wavelength incident fiber 51 and the beam splitter 52. In the second embodiment, the light source is a dual-frequency laser, and the beam splitter 52 is a laser frequency splitter. Specifically, the laser frequency splitter is an electro-optic modulator or an acousto-optic modulator. The interference module 60 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com