Lithium titanate battery pack charging method

A charging method and a technology of a battery pack, which are applied to secondary battery charging/discharging, secondary battery, secondary battery repair/maintenance, etc., can solve problems such as small drop in the maximum voltage of a single battery, and achieve fullness assurance and extended battery life. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to facilitate those skilled in the art to understand the technical content of the present invention, the present invention will be further described in detail below in conjunction with the embodiments.

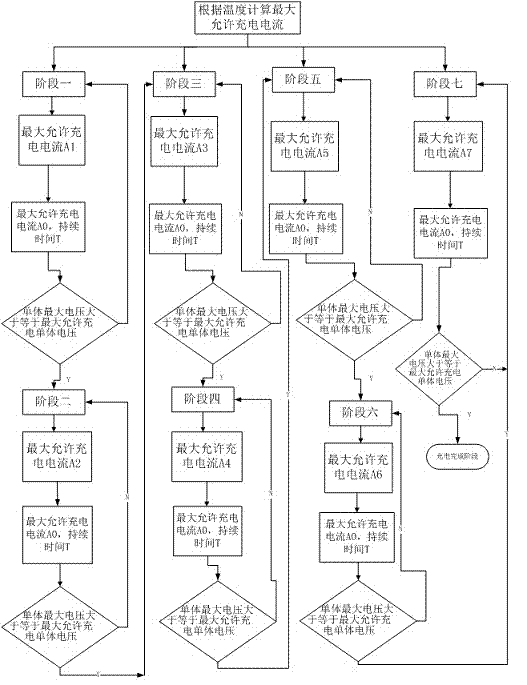

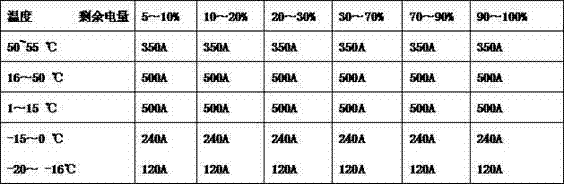

[0015] Such as figure 1 As shown, in this embodiment, the lithium titanate battery pack charging method divides each charging process into seven stages. In general, the first-time required charging current is set to A1, and the current drop amplitude is 30- 60A, the electric current when static buffering is set to I, and the static buffering time is T. Before charging each time, it is necessary to detect the remaining power of the battery pack and the current temperature information and look up the table to find the corresponding optimal charging current as the first demand current value to send the charging demand information, and then set the stage from the first demand current according to the following stages Start execution, and execute the following step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com