Multistage ultrashort pulse laser step-by-step compression system

A technology of ultra-short pulse laser and compression system, which is applied in the field of optics, can solve the problems of reducing the overall efficiency of the laser system, and achieve the effect of completely matching the amount of pulse stretching and compression, and reducing the amount of compression loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

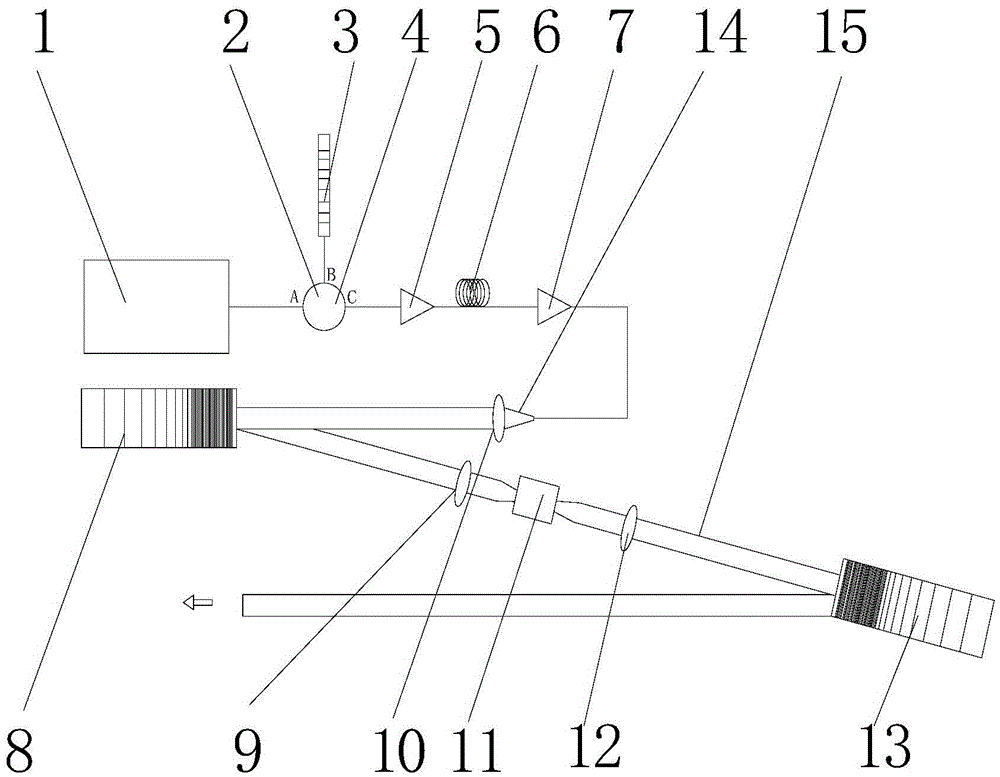

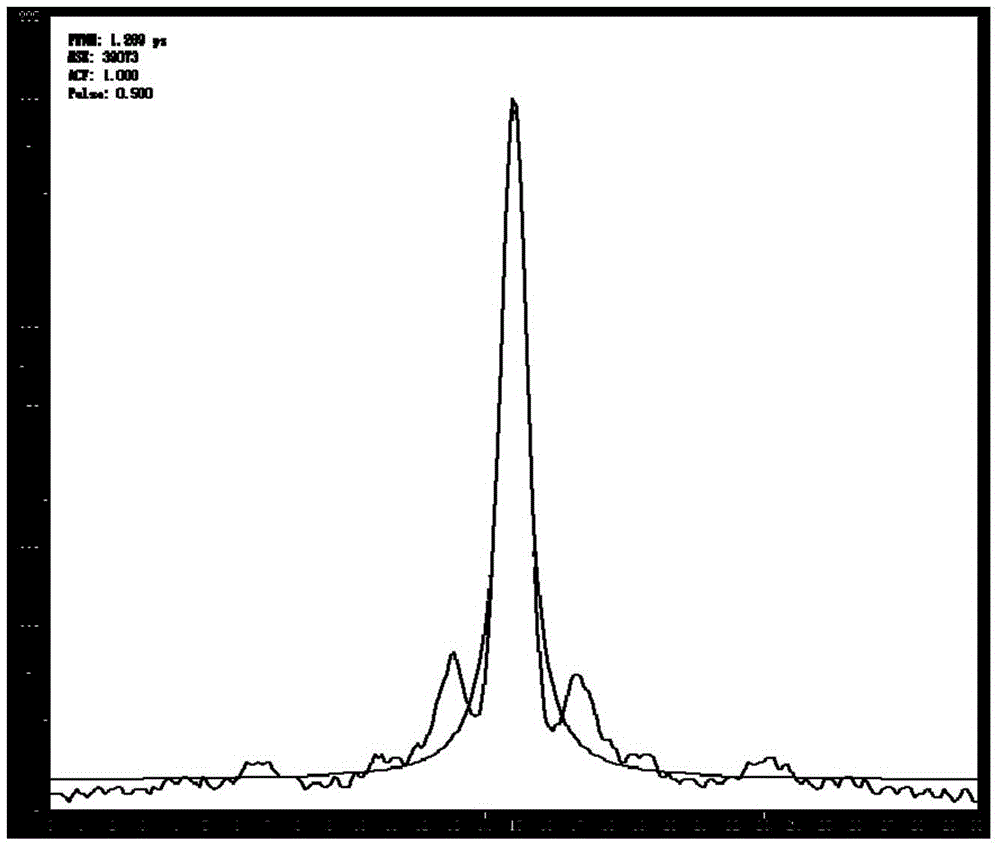

[0023] The present invention proposes the construction of an efficient and highly integrated ultrashort pulse laser step-by-step compression system based on volume chirped gratings, and verifies that multi-block chirped gratings can efficiently compress stretched pulses with arbitrary pulse widths.

[0024] The present invention is described in detail below:

[0025] A multi-stage ultrashort pulse laser step-by-step compression system, comprising an ultrashort laser pulse transmitter 1, a primary compression device 14 and a secondary compression device 15; wherein, the primary compression device 14 is arranged on the ultrashort laser pulse transmitter 1 on the outgoing optical path; wherein, the secondary compression device 15 is arranged on the diffraction optical path of the primary compression device 14; the included angle between the outgoing optical path of the ultrashort laser pulse transmitter 1 and the diffraction optical path of the primary compression device 14 is θ;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com