Rotor structure of permanent magnet motor

A technology of rotor structure and permanent magnet motor, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems of high processing cost, time-consuming, complicated processing, etc., and achieve convenient processing and manufacturing technology, The effect of simple and convenient processing and simple and convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

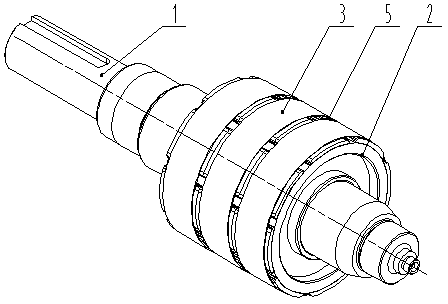

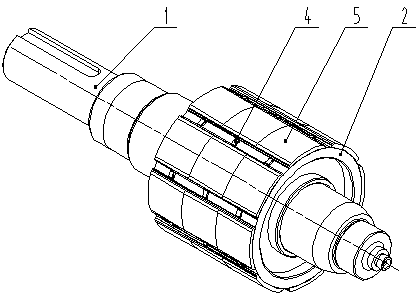

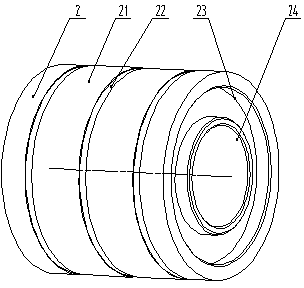

[0016] Such as figure 1 , figure 2 As shown, the permanent magnet motor rotor structure includes a shaft 1, a rotor core 2, a buckle sleeve 3, a retaining ring 4, and a magnetic steel 5. The structure diagram of this embodiment is a schematic diagram of a structure with three magnetic steels 5 in the axial direction. , the shaft 1 is press-fitted in the image 3 The core inner hole 24 of the rotor core 2, such as image 3 As shown, several grooves 22 are provided on the entire circumference of the outer circular surface 21 of the rotor core 2, and dynamic balance correction grooves 23 are provided on both ends, as shown in Figure 4 , Figure 5 As shown, the retaining ring 4 is provided with a boss 44, a positioning surface 43, an inner surface 42, and an outer surface 41. The width of the groove 22 of the rotor core 2 is slightly larger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com