Rice cooker temperature sensor

A temperature sensor and rice cooker technology, which is applied to thermometers, thermometers and instruments using electrical/magnetic components directly sensitive to heat, etc., can solve the problem of difficult casing collection, inflexible movement of the rice cooker temperature sensor up and down, and poor casing. The problem of gathering in the center, etc., to achieve the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

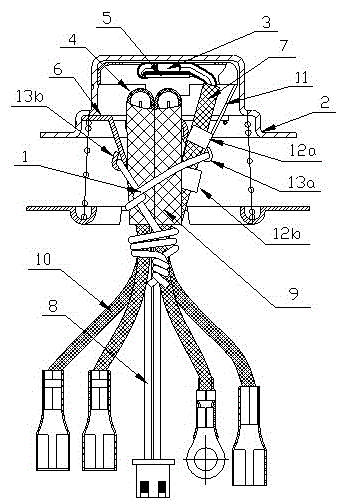

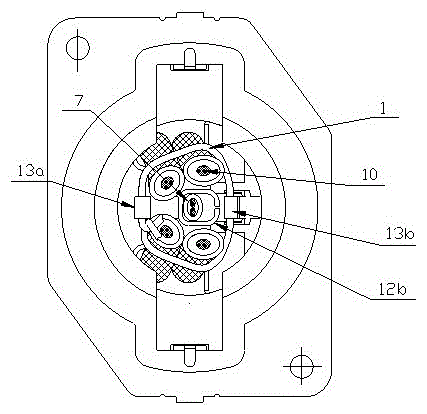

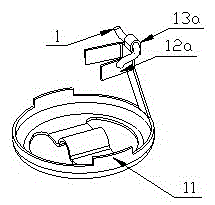

[0017] Such as figure 1 , 2 , 3, and 4, the electric cooker temperature sensor of the present embodiment includes a binding wire 1 and an aluminum cover 2, and a thermistor 3 and a thermal fuse 4 are installed in the aluminum cover 2 through a bracket, and the bracket includes an inner bracket 5 and the outer support 6, the thermistor 3 is fixed on the inner top of the aluminum cover 2 through the inner support 5, and the thermal fuse 4 is fixed at the lower position of the thermistor 3 through the outer support 6;

[0018] The thermistor 3 is set in the first insulating sleeve 7 and connected to the first wire 8 leading out of the aluminum cover 2. The thermal fuse 4 is set in the second insulating sleeve 9 and connected to the lead out It is connected to the second wire 10 outside the aluminum cover 2. The inner bracket 5 is integrally provided with an inner support claw 11 protruding downward. The inner support claw 11 is made of a T-shaped plate, and the horizontal positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com