Novel honeycomb electric field structure

A honeycomb structure and honeycomb technology, applied in the field of electrostatic oil fume removal, can solve the problems of frequent cleaning cycles and poor oil fume removal effect, and achieve the effects of simple and convenient installation, improved uniformity, and uniform adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

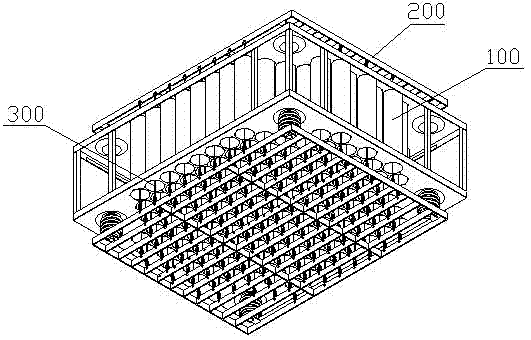

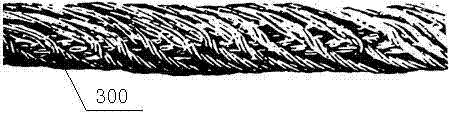

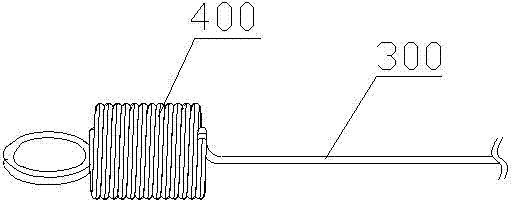

[0024] The invention discloses a novel honeycomb electric field structure, the schematic diagram of which is as follows figure 1 As shown, it includes a honeycomb structure. The honeycomb structure is generally composed of a plurality of oil fume removal channels 100 arranged in a row, and each oil smoke removal channel 100 is correspondingly provided with a cathode needle. Since the traditional cathode needle is made of a steel rod, the diameter of the steel rod is relatively large and the surface is smooth, the distortion of the electric field formed between the steel rod and the oil fume removal channel 100 is small, and the electron release ability is poor. This new honeycomb electric field structure in this embodiment adopts steel w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com