A processing method for guide vane edge plate of aero-engine

An aero-engine and guide vane technology, which is applied in the field of aero-engine turbine guide vane processing, can solve problems such as inconvenient positioning and edge plate deformation, and achieve the effect of ensuring dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

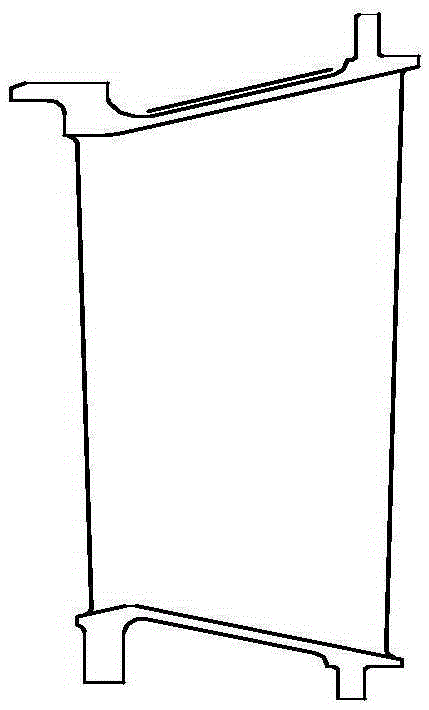

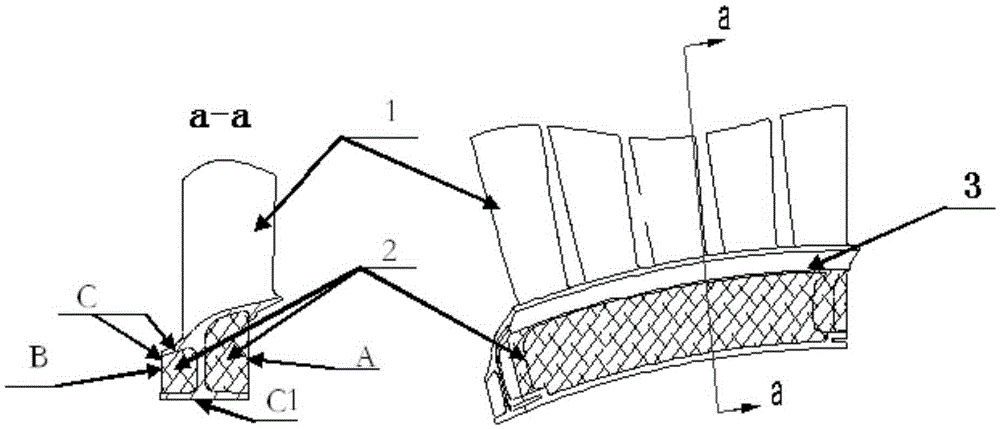

[0023] Embodiment 1, the processing steps of the lower edge plate of the "I"-shaped cantilever structure of the guide vane are as follows:

[0024] (1) Use adhesive tape to fix the cloth bakelite or hard paper on both ends of the "I"-shaped cantilever structure of the clean blade lower edge plate (leaf pot, leaf back side lower edge plate), at this time the cloth bakelite Two groove cavities with side openings are formed with the "I"-shaped structural edge plate; when parts are in large batches, a fixing fixture can be designed to cover the groove cavities.

[0025] (2) Put the blade down, at this time, the groove on one side is facing upwards, lay the self-setting toothpaste powder in the groove, and then pour the self-setting toothpaste water, so that the toothpaste water just covers the toothpaste powder It is advisable; after more than ten minutes, the tray powder will solidify by itself to form a solid filling resin; or you can directly fill the groove with green low-melt...

Embodiment 2

[0030] Example 2, the processing steps of the lower edge plate of another two-stage guide vane "J"-shaped cantilever structure of a certain type of low-pressure turbine are as follows:

[0031] (1) Use adhesive tape to fix the cloth bakelite or hard paper on both ends of the "J"-shaped cantilever structure of the clean blade lower edge plate (leaf pot, lower edge plate on the back side of the leaf), at this time the cloth bakelite Form a side-opened groove cavity with the "J"-shaped structural edge plate. When the parts are in large batches, a fixed fixture can be designed to cover the formed cavity;

[0032] (2) Put the blade down, and at this time, the groove on one side is facing upwards, lay the toothpaste powder in the groove, the first layer is about 5mm thick, and it needs to be flat, then pour the self-setting toothpaste water, the toothpaste The ratio of the tray powder to the tray water is 10g: 5ml. It is advisable that the tray water just submerges the tray powder, ...

Embodiment 3

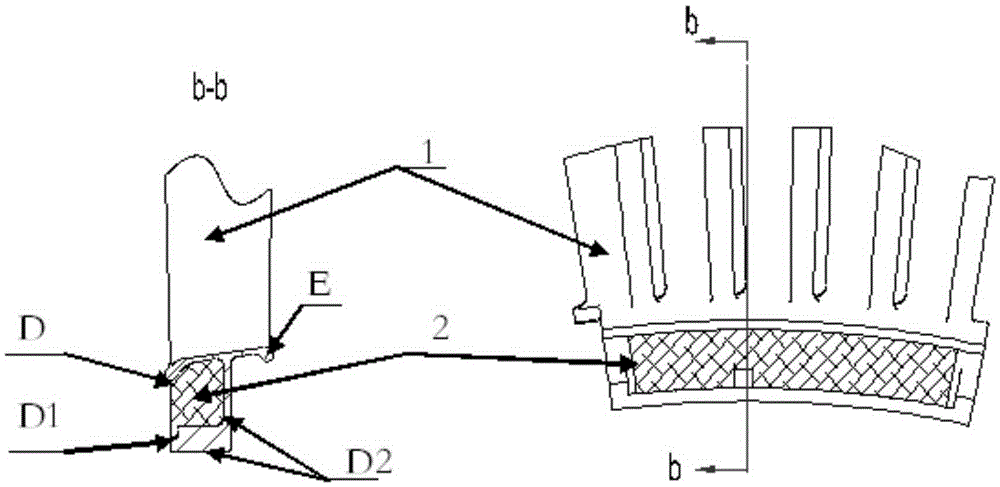

[0037] Embodiment 3, the processing steps of another welding assembly of high guide vane are as follows:

[0038] (1) in Figure 4 The guide vane edge plate shown has a number of exposed small cylinders (Φ0.8-Φ1.2). The partial area is filled with tray powder, and then poured with tray water. The ratio of tray powder to tray water is as follows: 10g: 5ml ratio, it is advisable to fill the groove with the tray water just submerged in the tray powder, mix it a little bit, and wait for more than ten minutes for the tray powder to solidify by itself to form a strong filling resin;

[0039] (2) Grinding the filling area, use a powerful slow-feed five-axis grinder MC607 or MFP50, and use a medium-pore grinding wheel to prevent the resin from blocking the pores of the grinding wheel and causing blade burns. The grinding wheel brand:

[0040]P350 (or 300) × 25 × 75 (76.2) WA70F9V35

[0041] (3) After the processing dimensions are all measured and qualified, the blades are put into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com