Four-freedom-degree fine adjustment device

A technology of fine-tuning devices and degrees of freedom, applied in metal processing, metal processing equipment, workshop equipment, etc., can solve the problems of difficult to ensure the installation accuracy of parts, low installation efficiency, and failure to meet installation requirements, etc., to achieve light weight and improve efficiency , good maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

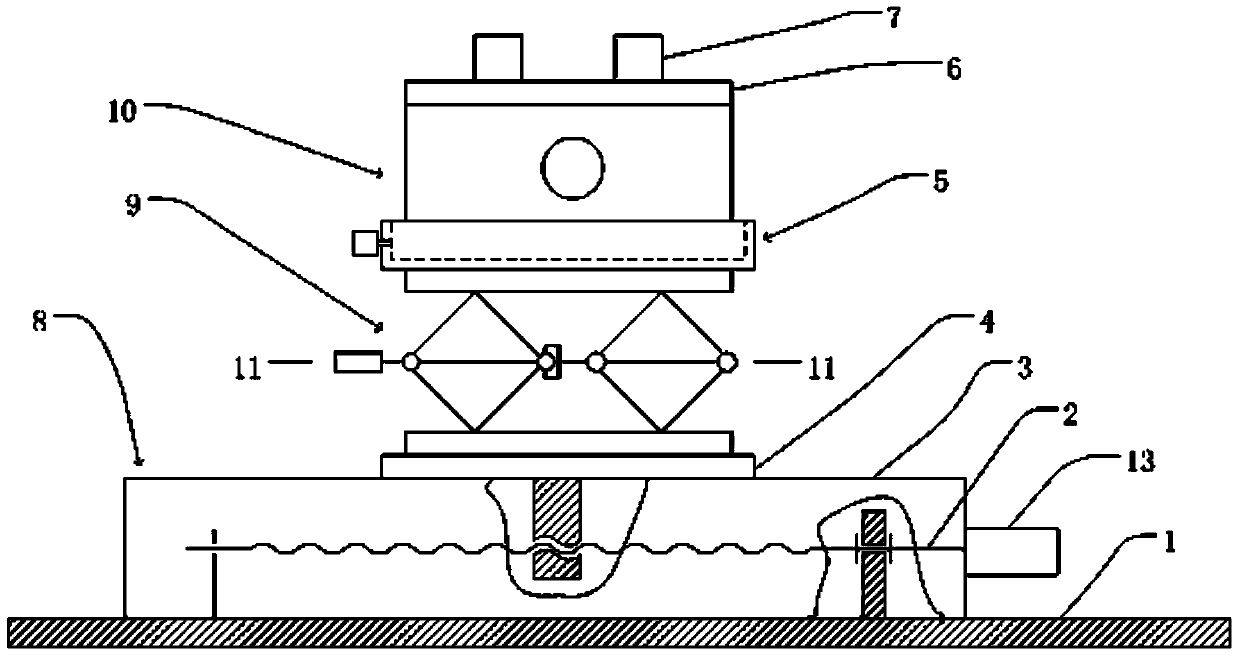

[0018] See figure 1 , The entire four-degree-of-freedom fine-tuning device is installed on the platform 1.

[0019] The horizontal moving table 8 (10) is mainly composed of the motor 13, the lead screw 2, the guide rail 3, and the sliding plate 4. Through the preset stroke, the measurement and transmission of the lead screw are used to control the motor 13 to drive the lead screw 2 to rotate. The sliding plate 4 is driven to move on the guide rail 3. This device greatly improves the mobility of the device system, and is especially suitable for precision installation of large systems. When the degree of freedom is not high, this horizontal mobile station can be used individually and adopt a suitable installation method.

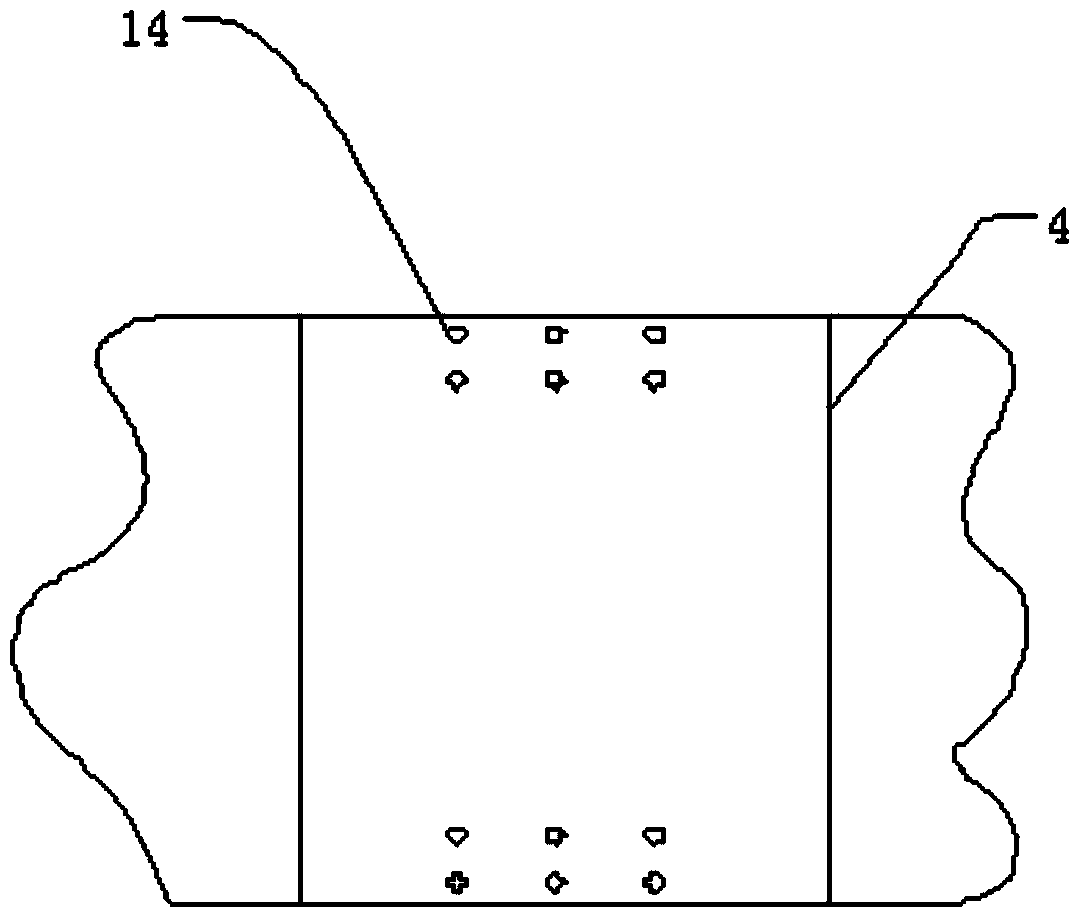

[0020] See figure 2 , 2*3 cones are distributed on both sides of the sliding plate 4 (6). Through the measurement of the joint arm coordinates, the coordinates can be determined, and the movement and rotation of the two water platforms and the rotating table can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com