Unstressed flattening device and method for cylindrical bamboo wood with bamboo green and tabasheer

A stress-free, bamboo-spring technology, applied in the direction of mechanical equipment, sugarcane machining, etc., can solve the problems of flattening, cracking and flattening effects, complex equipment structure, and the existence of stress, and achieve simple and scientific structure, good leveling effect, and easy operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

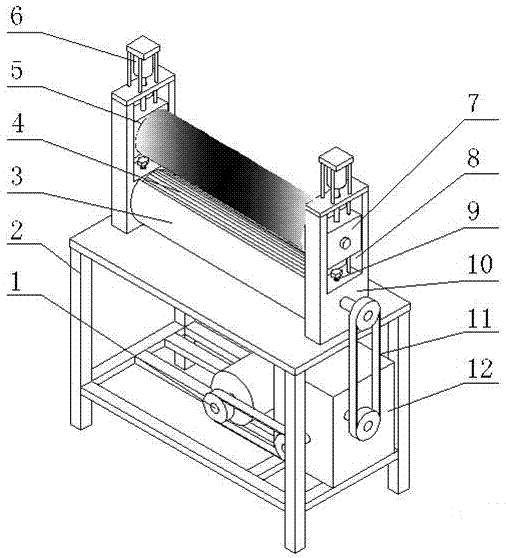

[0016] control figure 1 , a tubular bamboo stress-free flattening device with bamboo green and bamboo spring, its structure includes motor 1, machine base 2, protective cover 3, knife roller 4, leveling roller 5, cylinder 6, leveling roller bearing sliding seat 7, chute 8, limit bolt 9, cutter roller bearing holder 10, chain 11, gearbox 12, wherein, motor 1 and gearbox 12 are installed below the support 2, and cutter roller 4 is arranged above the support 2 And the leveling roller 5, the knife roller 4 is fixedly installed with the machine base 2 through the knife roller bearing fixing seat 10, and the leveling roller 5 is installed in the chute 8 above the knife roller bearing fixing seat 10 through the leveling roller bearing sliding seat 7, The knife roller 4 and the leveling roller 5 are on the same vertical plane, the leveling roller bearing sliding seat 7 can only slide up and down in the chute 8, and the limit bolt 9 is located between the knife roller bearing fixing se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com