Manufacturing method and equipment of high temperature resistant ceramic cyclone

A technology for high-temperature resistant ceramics and manufacturing equipment, applied in manufacturing tools, ceramic molding machines, molding indenters, etc., can solve the problems of difficult to guarantee quality, low production efficiency, size restrictions, etc., to achieve high production efficiency, improve yield, The effect of good quality of cross-section roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

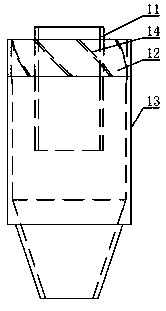

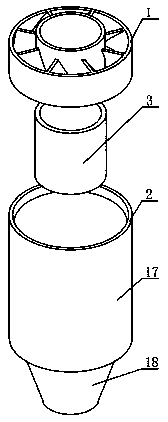

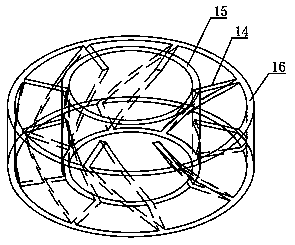

[0029] Such as figure 2 As shown, the cyclone cylinder of the high-temperature-resistant ceramic cyclone guide according to the present invention includes two main components of the cyclone 1 and the cylinder body 2, and other components such as the straight pipe 3. Each component structure is independently manufactured and fired, assembled When the cyclone separator forms a whole cyclone tube. Among them, see image 3 The cyclone 1 includes an upper exhaust pipe 15 as an inner cylinder, an upper outer cylinder 16 as an outer cylinder, and several parallel swirl guide vanes 14 between the inner and outer cylinders. The height of the inner and outer cylinders is the same as that of the blades 14 About the same height. The cylinder body 2 includes a straight cylinder section 17 and a cone cylinder section 18. The inner and outer diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com