Multifunctional combed plate dryer

A flat-panel dryer and multi-functional combination technology, applied in the direction of fat production, fat oil/fat production, etc., can solve problems such as unsatisfactory heat transfer coefficient, inconvenient transportation, unreasonable structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

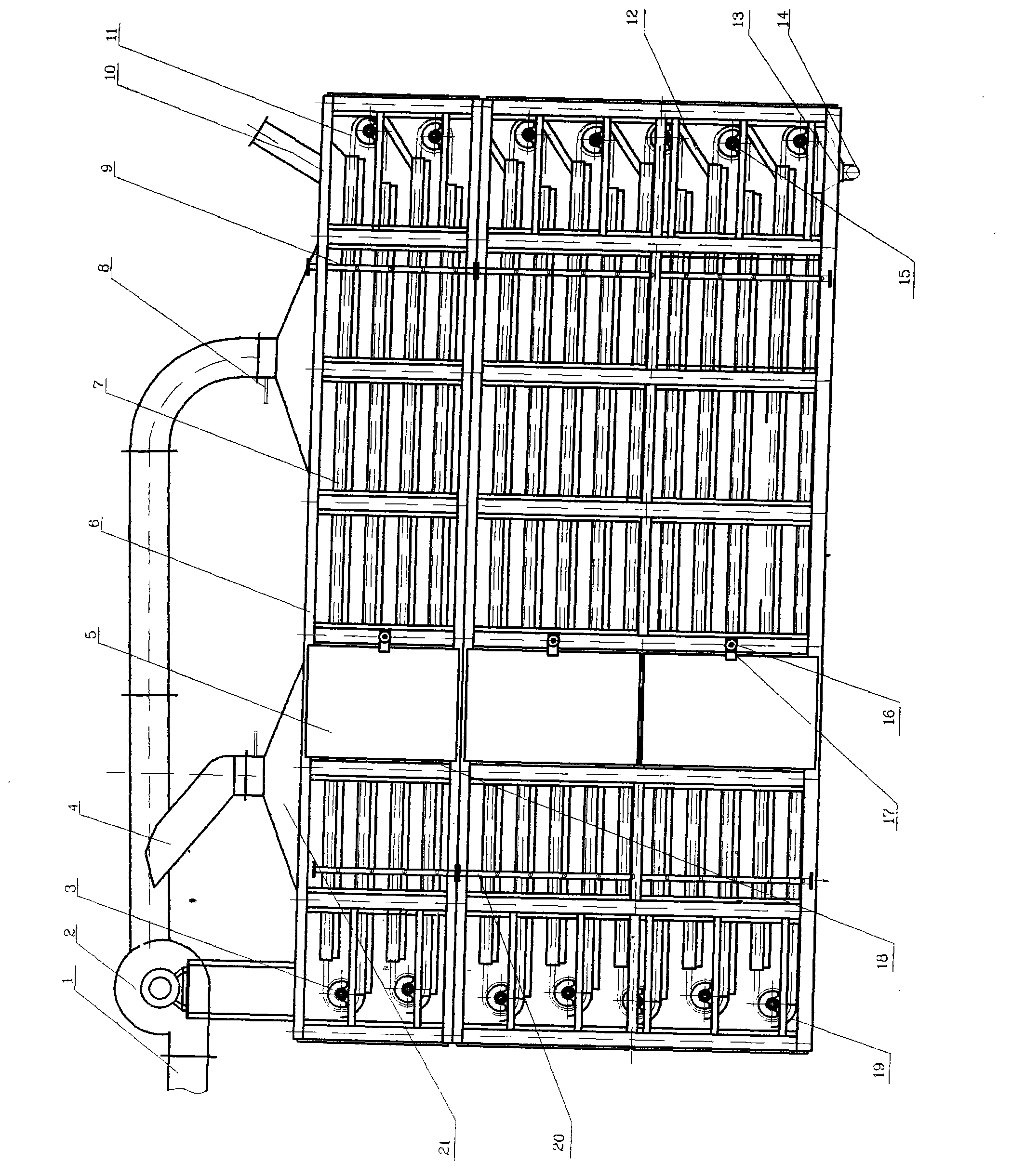

[0006] Products involved in the present invention, such as figure 1 The shown frame 6 is welded by channel steel profiles. Frame 6 is provided with threaded handle 16, pressing plate 17, door shaft 18 and insulation door panel 5 is fixed on the frame, and adjusting threaded handle 16, pressing plate 17 realizes the opening and closing of insulation door panel. The inside of the frame 6 is provided with multi-layer heating bed boards 7, and each layer of heating bed boards 7 is provided with a heat transfer medium inlet pipe and an outlet pipe; the inlet pipe is connected with the heat transfer medium inlet pipe 9, and the outlet pipe is connected with the heat transfer medium outlet pipe 20 . Be provided with head wheel 3, tail wheel 15 at appropriate position above every layer of heating bed plate 7, be provided with mine chain 11 between head wheel 3, tail wheel 15. A scraper is provided on the mine chain 11, and the scraper is driven to move by driving the mine chain 11 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com