Vacuum evaporation source capable of being mounted at any angle for use

A technology of vacuum evaporation and any angle, which is applied in the direction of vacuum evaporation plating, ion implantation plating, metal material coating process, etc., and can solve problems such as the interface is in an idle state, the number of available interfaces is reduced, and the upward interface is not enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

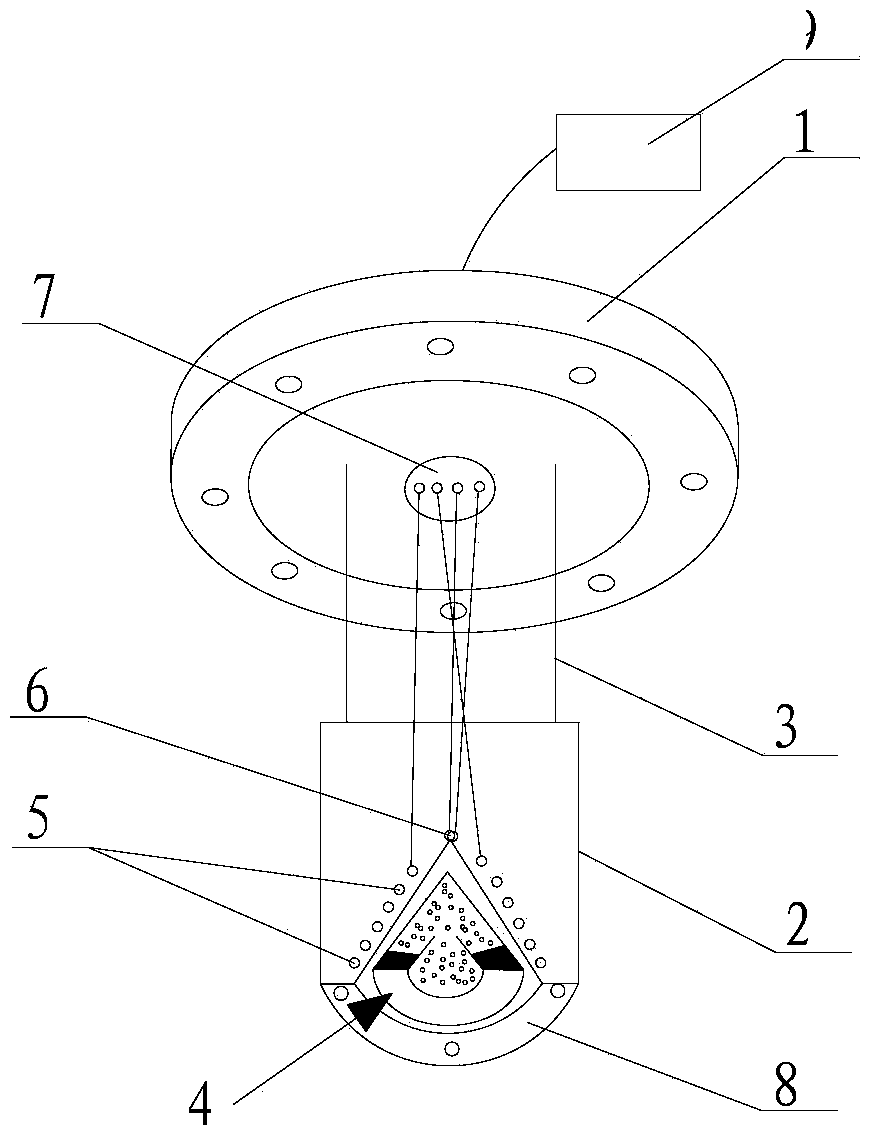

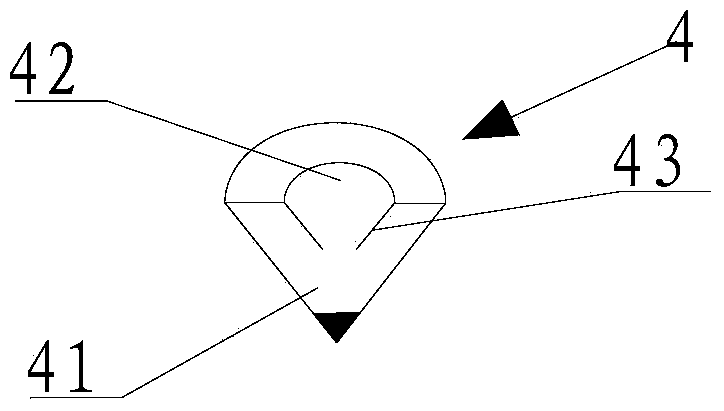

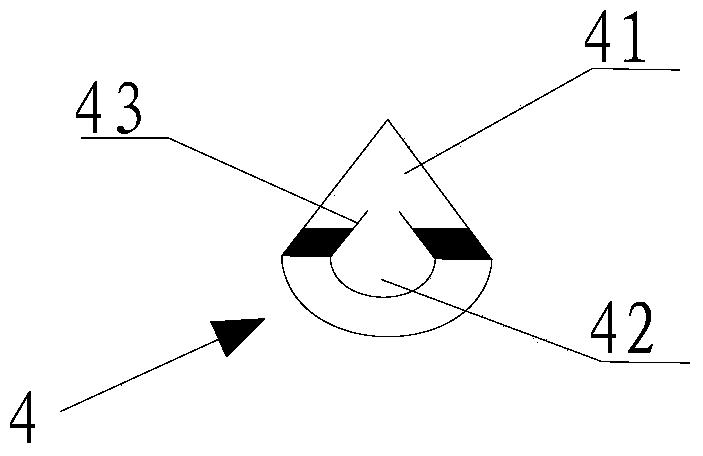

[0024] Such as Figures 1 to 2 The shown vacuum evaporation source mainly includes a vacuum flange 1 , a heat shielding component 2 , a container 4 , a heating component 5 , a temperature measuring component 6 and a vacuum electrical connector 7 .

[0025] Among them, the vacuum flange 1 can be used to support the heat shield assembly 2; the container 4 is detachably embedded in the end of the heat shield assembly 2 away from the vacuum flange 1, and is used to hold the evaporation material; the heating assembly 5 is fixed in the heat shield assembly 2 , for the built-in container 4 and thereby it is heated; the temperature measuring assembly 6 is installed near the container 4, and is used to measure the temperature of the container 4; the vacuum electrical connector 7 is installed on the vacuum flange 1, respectively with the heating asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com