Forming method and device of metal ions via passing through deposition and bilateral constraint

A metal ion and electroplating metal technology, which is applied in the direction of electrolytic coating, coating, plating tank, etc., to achieve low-cost characteristics and solve the effect of direct electroforming processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

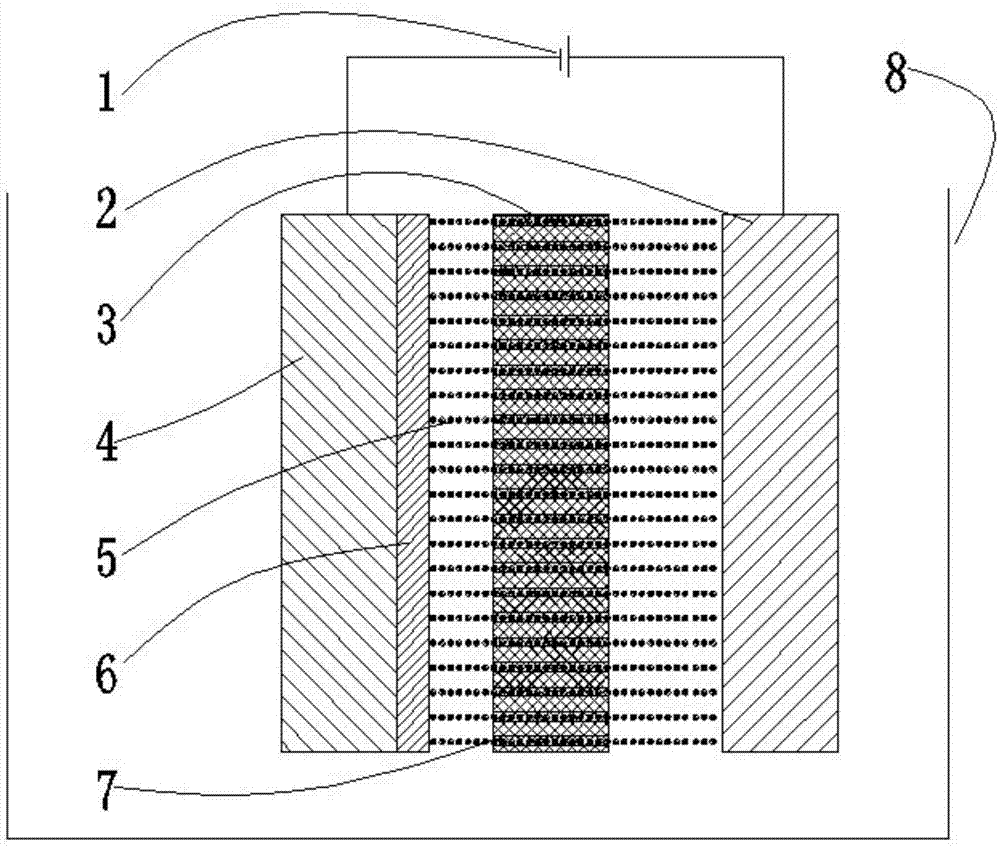

[0029] Figure 1a Schematic diagram of the structure of the metal ion through deposition and bidirectional confinement forming device;

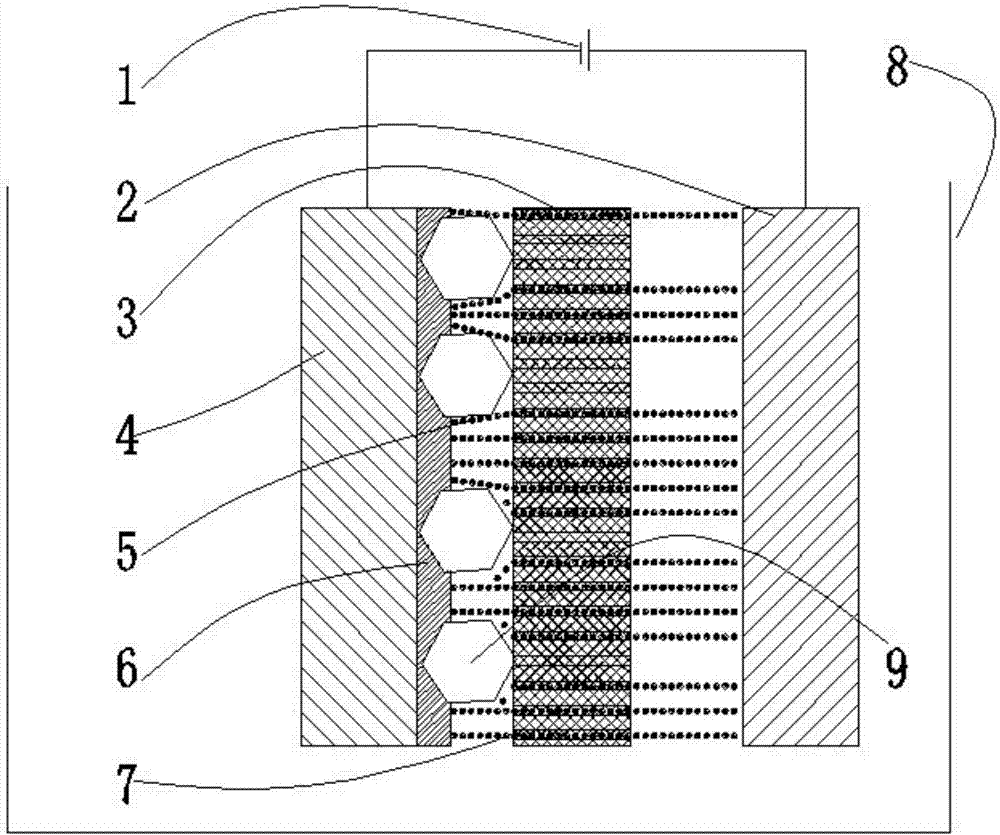

[0030] Figure 1b Schematic diagram of the metal ion cross-deposition and bidirectional confinement forming device used to make electroplated grinding wheel blocks;

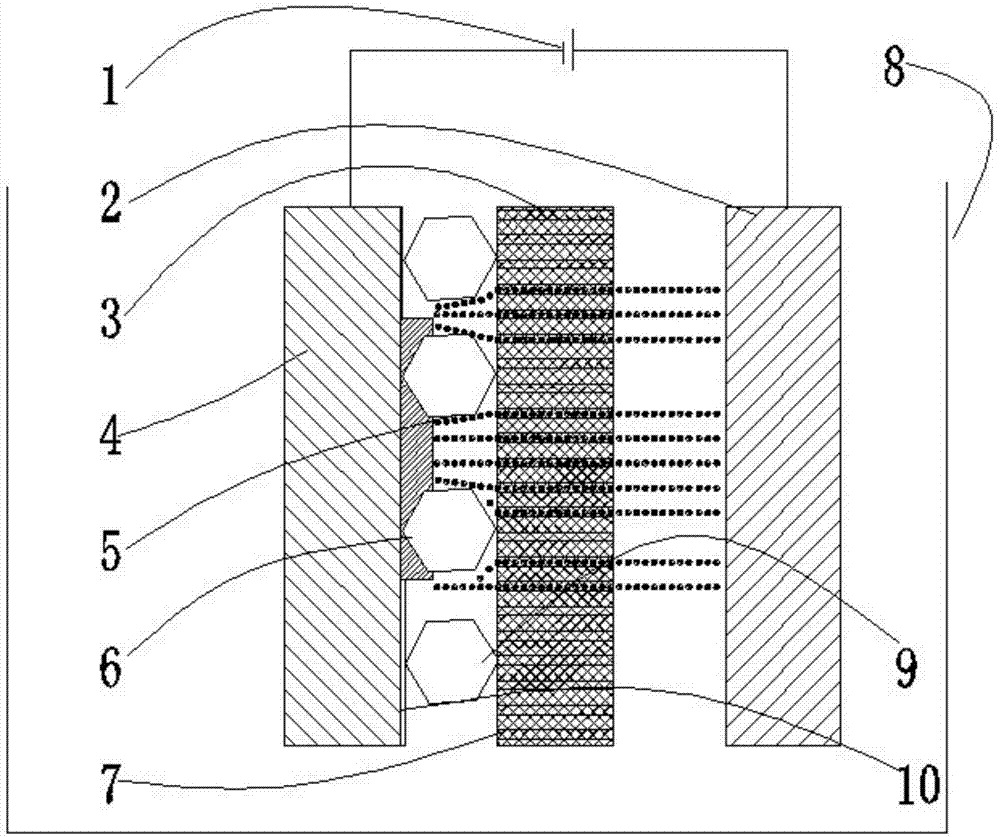

[0031] Figure 1c Schematic diagram of a region-selective electroplating wheel block for the metal ion traverse deposition and bidirectional confinement forming device;

[0032] Figure 2a An example diagram for making complex precision electroplated grinding wheels by using natural accumulation and ion passing through deposition, Figure 2b An example diagram for making complex and precise electroplating grinding wheels by centrifugal stacking and ion crossing deposition; Figure 2a Among them, 1 is the power supply and its control system; 2r is the electroplating metal material; 3r is the outer mold; 4r is the grinding wheel substrate; 5 is the metal ion; 6 is the electrop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com