Simple aerial work platform erection method

A kind of high-altitude work platform and simple technology, which is applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of troublesome disassembly work, time-consuming materials and inconvenient erection methods, and reduce high-altitude cutting and repair. Grinding, reducing engineering costs, reducing troubles and safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The simple aerial work platform erecting method of the present invention is used for aerial butt joint installation of outdoor independent chimneys, and is characterized in that it includes the following steps:

[0028] a, C-type plate production and welding

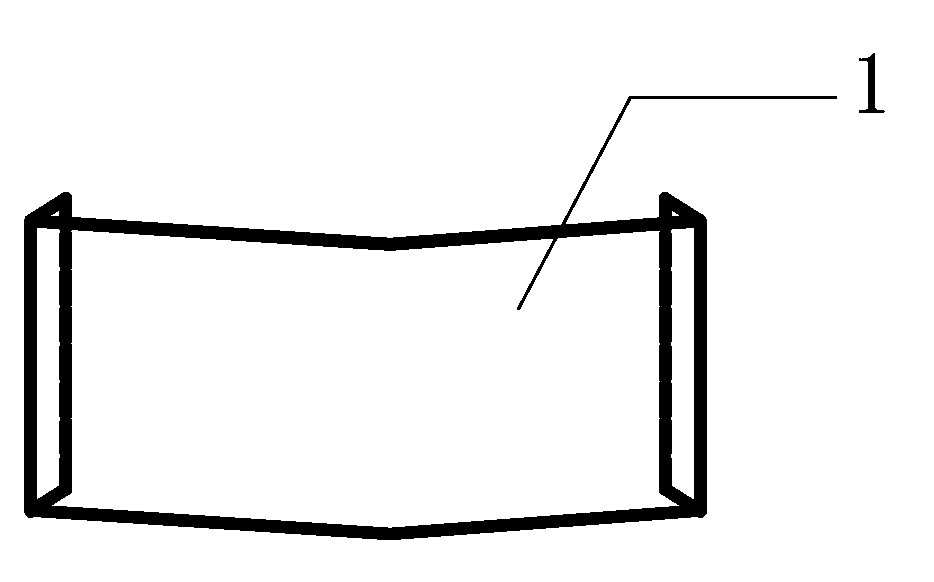

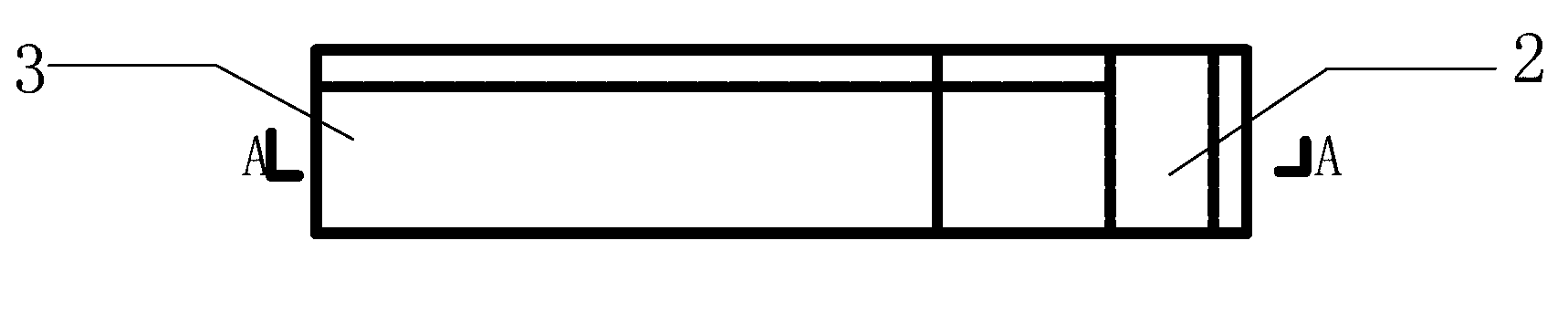

[0029] see now figure 1 and figure 2 , figure 1 It is a schematic diagram of a C-shaped steel plate blank in an embodiment of the present invention, figure 2 It is a schematic structural diagram of a C-shaped steel plate in an embodiment of the present invention.

[0030] Provide 5 rectangular steel plates, each of which is 120mm in length, 50mm in width, and 8mm in thickness; bend the rectangular steel plate into a C-shape, and bend each end of the C-shape by 10mm, and the arch length of the C-shape arc is 100mm, thus Make a C-shaped steel plate 1; evenly distribute the C-shaped steel plate 1 and fully weld it on the circumference of the suspended component body, so that there is a gap of 15mm to 20mm betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com