Structure of high-integration-density fuel cell with compensation ability

A high-integration, fuel cell technology, applied in fuel cells, structural parts, battery pack parts, etc., can solve the problem of reducing the volume specific power and weight specific power of the stack, increasing the space and weight of the stack, and the compensation effect is not enough. Ideal and other issues, to achieve the effect of improving volume specific power and weight specific power, saving space, and reducing the types of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing and example.

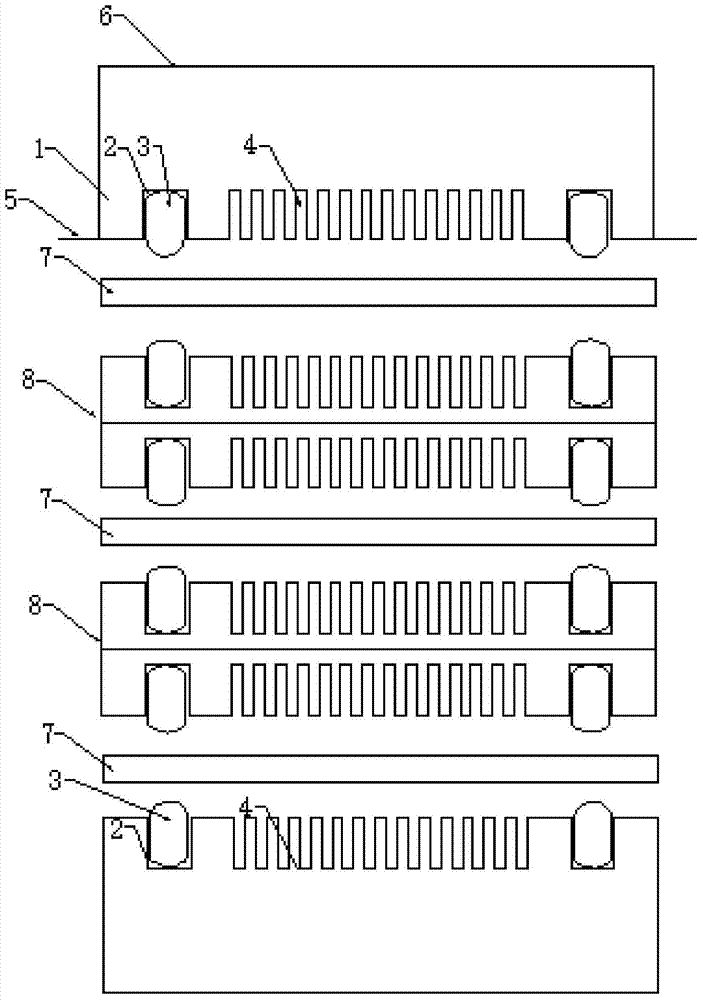

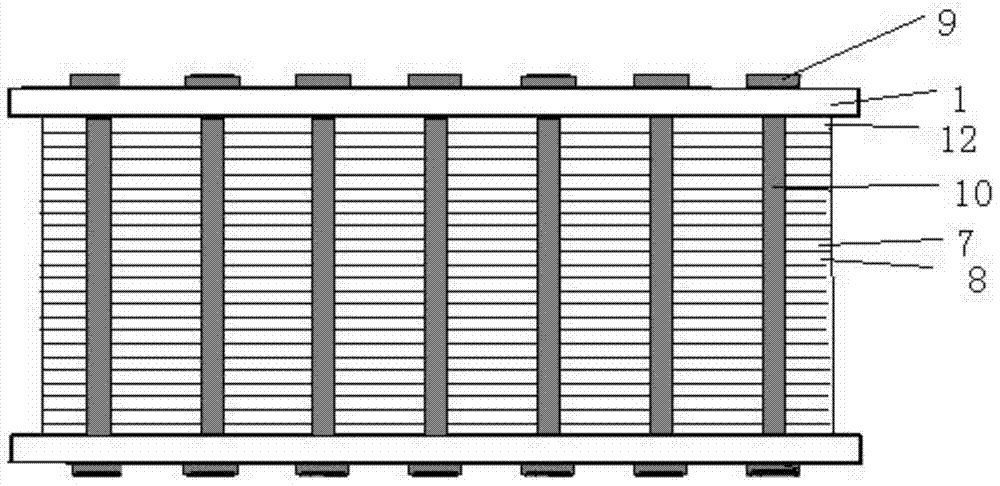

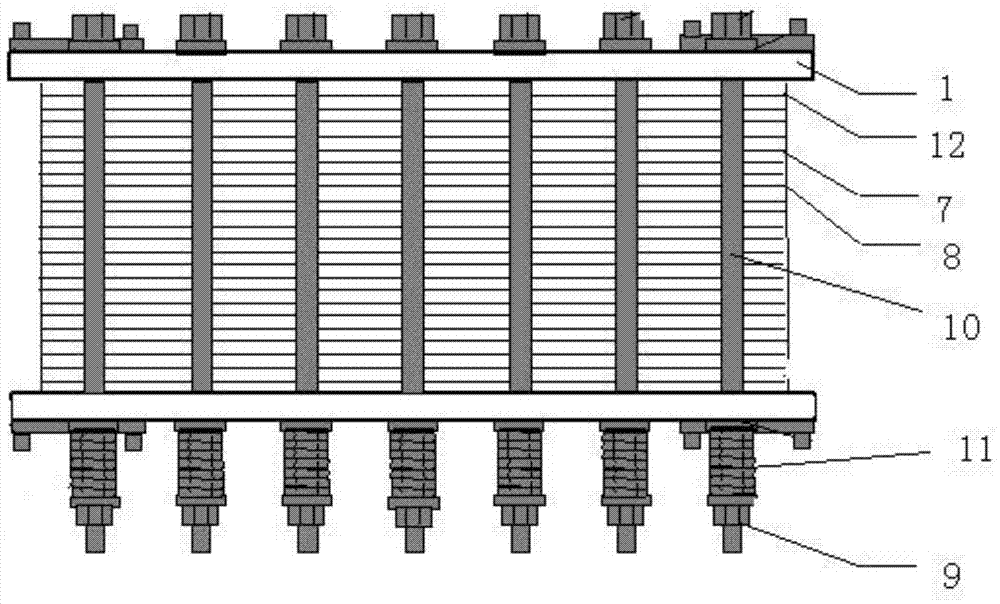

[0012] The end plate 1 is made of antimony, bismuth or gallium alloy materials that expand and contract with heat. There is no compensation spring on the end plate 1, and the inner side of the end plate is provided with an end plate sealing groove 2, an end plate sealing rubber ring 3, The plate flow field 4 and the conductive modification tab 5 inside the end plate. The fuel cell stack is assembled in the following order: end plate 1 at one end, bipolar plate 8, membrane electrode (MEA) 7, bipolar plate 8, membrane electrode (MEA) 7..., until the last membrane electrode (MEA) 7, then place the current collecting plate 12 and the end plate 1 at the other end, use the screw 10 and the nut 9 to tighten the two end plates and the bipolar plate between the two end plates, the membrane electrode (MEA) and the current collecting plate Fixed connection. Compared with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com