A method for separating insulation layers of electromagnetic wires

A separation method and electromagnet wire technology, applied in the direction of dismantling/armoring cable equipment, etc., can solve the problems of large power, long time, easy to pollute the environment, etc., and achieve the effect of reasonable design, easy replacement and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

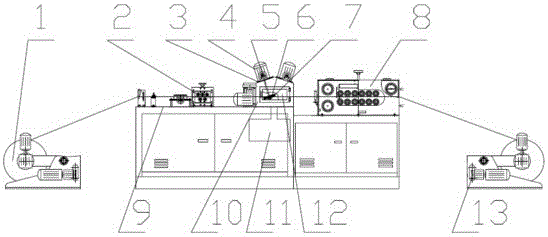

[0072] A device for separating the insulating layer of electromagnetic wires. When working, the straightening device 2, the stripping mechanism, the dust collecting device 11 and the traction mechanism 8 are fixed on the platform 9, the wire releasing mechanism 1 is placed in front of the platform 9, and the wire take-up mechanism 13 is placed on the After platform 9. Putting in the magnet wire is thin film burning copper flat wire. The straightening device includes a horizontal straightening wheel set and a vertical straightening wheel set, and the gap between the wheel sets is adjusted so that the straightening wheels are close to the copper wire for straightening. Stripping mechanism comprises stripping box 10, guide rail 3, motor 4, metal rod 5, stripping wheel 6, bolt 7 and transparent baffle 12, can observe the situation inside the stripping mechanism by transparent baffle 12. Each stripping wheel 6 is connected with a motor 4 by a metal rod 5, and the rotation of the m...

Embodiment 2

[0074] A device for separating the insulating layer of electromagnetic wires. When working, the straightening device 2, the stripping mechanism, the dust collecting device 11 and the traction mechanism 8 are fixed on the platform 9, the wire releasing mechanism 1 is placed in front of the platform 9, and the wire taking mechanism 13 Placed behind platform 9. Put in the magnet wire as an enamelled copper round wire. The straightening device 2 includes a horizontal straightening wheel set and a vertical straightening wheel set, and the gap between the wheel sets is adjusted so that the straightening wheels are close to the copper wires to perform straightening. Stripping mechanism comprises stripping box 10, guide rail 3, motor 4, metal bar 5 stripping wheels 6, bolt 7 and transparent baffle 12, can observe the situation inside the stripping mechanism by transparent baffle 12. Each stripping wheel 6 is connected with a motor 4 by a metal rod 5, and the rotation of the motor 4 d...

Embodiment 3

[0076] A device for separating the insulating layer of electromagnetic wires. When working, the straightening device 2, the stripping mechanism, the dust collecting device 11 and the traction mechanism 8 are fixed on the platform 9, the wire releasing mechanism 1 is placed in front of the platform 9, and the wire taking mechanism 13 Placed behind platform 9. Put in the magnet wire as wire-clad copper square wire. The straightening device 2 includes a horizontal straightening wheel set and a vertical straightening wheel set, and the gap between the wheel sets is adjusted so that the straightening wheels are close to the copper wires to perform straightening. The peeling mechanism comprises a peeling box, a guide rail 3, a motor 4, a metal rod 5, a peeling wheel 6, a bolt 7 and a transparent baffle 12, through which the internal situation of the peeling mechanism can be observed. Each stripping wheel 6 is connected with a motor 4 by a metal rod 5, and the rotation of the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com