Method for separating pigment molecules from hirudin fermentation broth

The technology of hirudin and fermentation broth is applied in the field of separation and purification of biomedicine, and achieves the effects of simple operation and short separation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

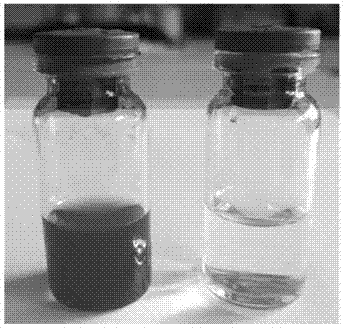

Image

Examples

Embodiment 1

[0028] 100L tank high-density fermentation, centrifuged to obtain hirudin fermentation broth volume 35L, secreted hirudin expression: 1.2mg / ml, protein activity: 16800IU / ml.

[0029] Pretreatment of hydrophobic chromatographic packing: take 3000g of hydrophobic chromatographic packing, particle size of hydrophobic chromatographic packing is 20μm, pore size Put it in a 15000ml container, add 15000ml of 95% ethanol and shake it evenly, put it in an ultrasonic cleaner and vibrate for 15min, add it into a Buchner funnel and filter to remove ethanol, rinse with 15000ml of distilled water, and then rinse with 40mmol / L PB with a pH of 4.8 until The pH of the effluent was 4.8, drained and stored at 4°C for later use. Rinse with 6L of equilibrium solution before use, and then drain it and use it directly for subsequent adsorption.

[0030] Get 2800g of pretreated hydrophobic chromatographic filler (dry weight), put it in the centrifuged hirudin fermentation broth (add 4mol / L sodium c...

Embodiment 2

[0036] High-density fermentation in 100L tank, centrifuged to obtain hirudin fermentation broth volume 38L, secreted hirudin expression: 1.15mg / ml, activity: 16100IU / ml.

[0037] Pretreatment of hydrophobic chromatographic packing: take 3100g of hydrophobic chromatographic packing, particle size of hydrophobic chromatographic packing is 20μm, pore size Put it in a 15000ml container, add 15000ml of 95% ethanol and shake it evenly, place it in an ultrasonic cleaner and vibrate for 20min, add it into a Buchner funnel and filter to remove ethanol, rinse with 15000ml of distilled water, and then rinse with 60mmol / L PB with a pH of 5.2 until The pH of the effluent was 5.2, drained and stored at 6°C for later use. Rinse with 6L of equilibrium solution before use, and then drain it and use it directly for subsequent adsorption.

[0038] Get 3000g of pretreated hydrophobic chromatographic filler (dry weight), put it in the centrifuged hirudin fermentation broth (add 3mol / L sodium chl...

Embodiment 3

[0044] 100L tank high-density fermentation, centrifuged to obtain hirudin fermentation broth volume 40L, secreted hirudin expression: 1.08mg / ml, protein activity: 15800IU / ml.

[0045] Pretreatment of hydrophobic chromatographic packing: take 3200g of hydrophobic chromatographic packing, particle size of hydrophobic chromatographic packing is 20μm, pore size Put it in a 15000ml container, add 15000ml of 95% ethanol to shake well, put it in an ultrasonic cleaner and vibrate for 20min, add it into a Buchner funnel and filter to remove ethanol, rinse with 15000ml of distilled water, and then rinse with 50mmol / L PB with a pH of 5.0 to The pH of the effluent was 5.0, drained and stored at 4°C for later use. Rinse with 6L of equilibrium solution before use, and then drain it and use it directly for subsequent adsorption.

[0046] Get 3100g of pretreated hydrophobic chromatographic filler (dry weight), put it in the centrifuged hirudin fermentation broth (add 2mol / L sodium chloride ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com