Plate tail material cutting and processing device

A technology for processing devices and plates, applied in the direction of shearing devices, feeding devices, positioning devices, etc., can solve the problems of increasing labor intensity of workers, reducing work efficiency, scraping of plates, etc., to reduce labor intensity of workers and improve utilization rate , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

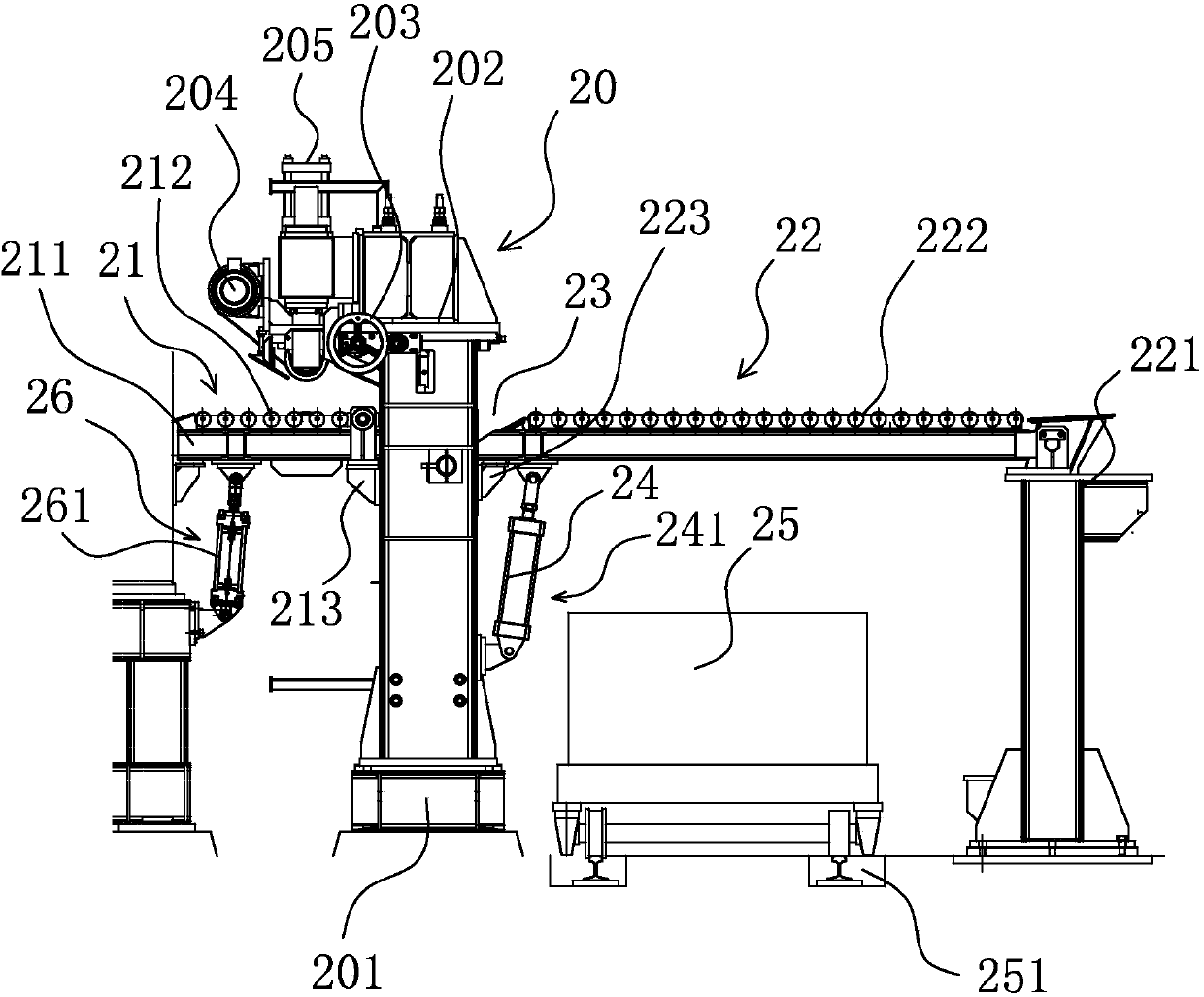

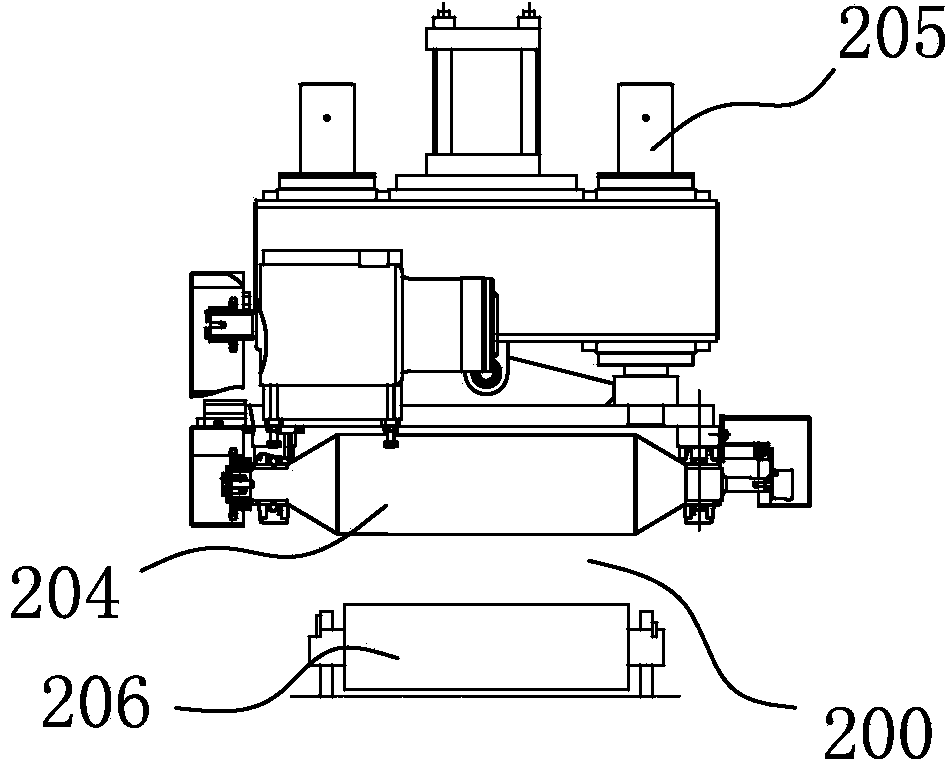

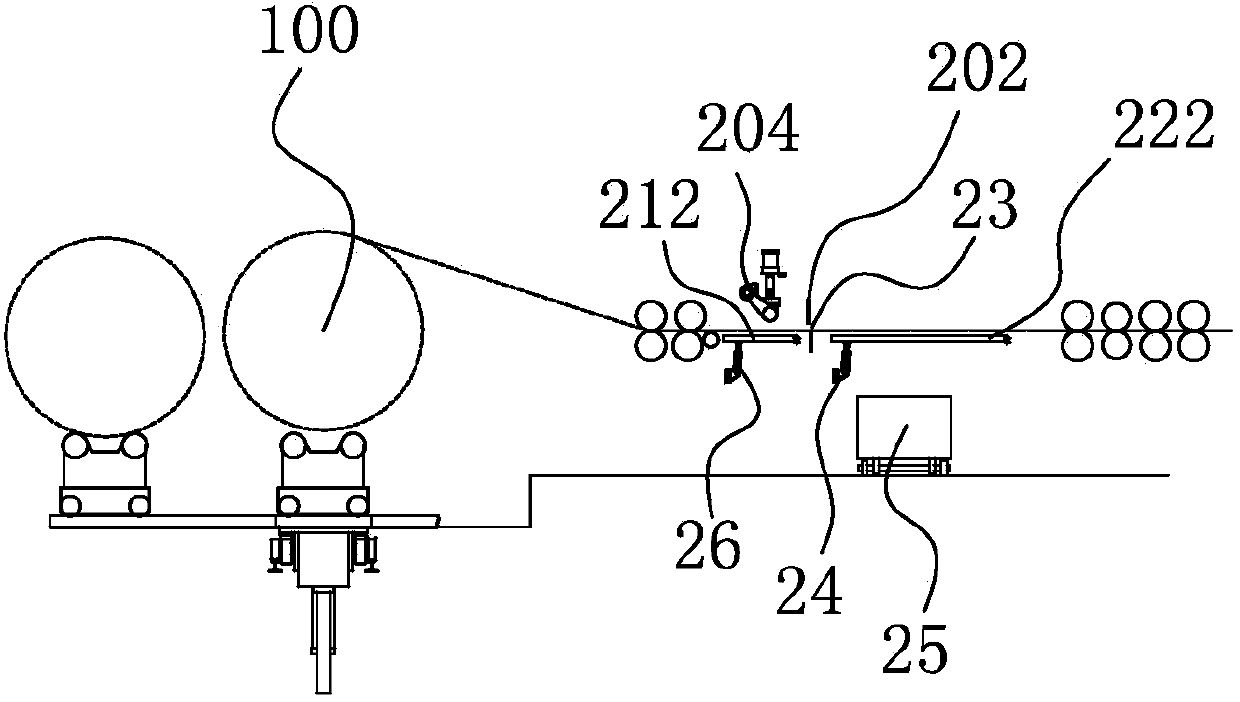

[0016] like Figure 1-3 As shown, a plate tail material cutting and processing device, the device includes a cutting mechanism 20 for cutting plates, on both sides of the cutting mechanism 20 are respectively provided with an entry-side conveying platform 21 and an exit-side conveying platform 22, in the cutting mechanism 20 is provided with a sheet material channel 200 for sheet metal to be conveyed from the entry-side conveying platform 21 to the exit-side conveying platform 22. A first lifting mechanism 24 forming the discharge port 23 is formed. The first lifting mechanism 24 includes an outlet side cylinder 241 arranged below the outlet side delivery mechanism 222 , one end of the outlet side cylinder 241 is hinged with the cutting mechanism 20 , and the other end is close to the end of the outlet side delivery mechanism 222 near the cutting mechanism 20 hinged.

[0017] A recovery trolley 25 is arranged below the delivery platform 22 on the exit side, and the recovery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com