Remote implementation method based on industrial inkjet printer control system

An implementation method and technology of a control system, applied in the field of industrial control, can solve the problems of affecting physical health, harmful to skin, body and organs, and high cost, and achieve the effects of being conducive to centralized control, saving production costs, and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

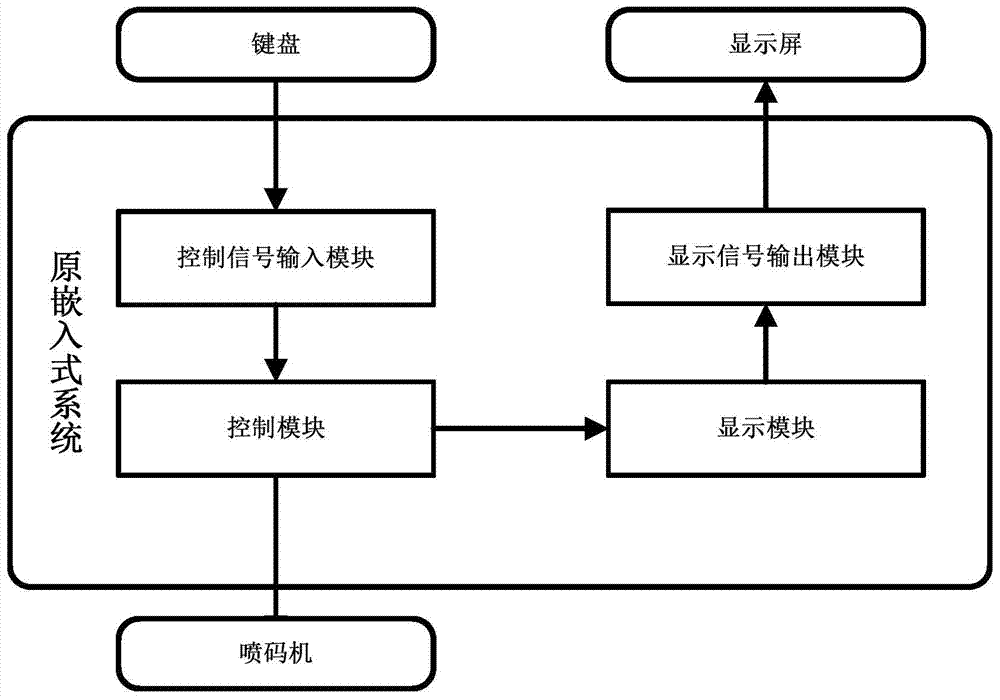

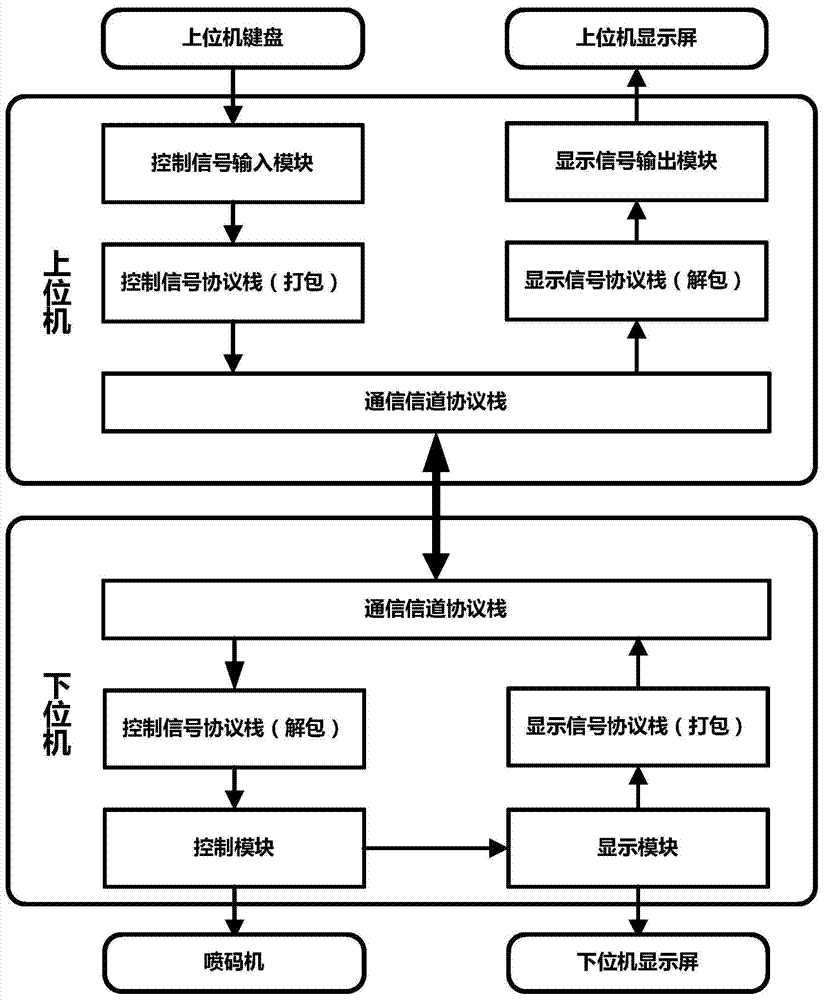

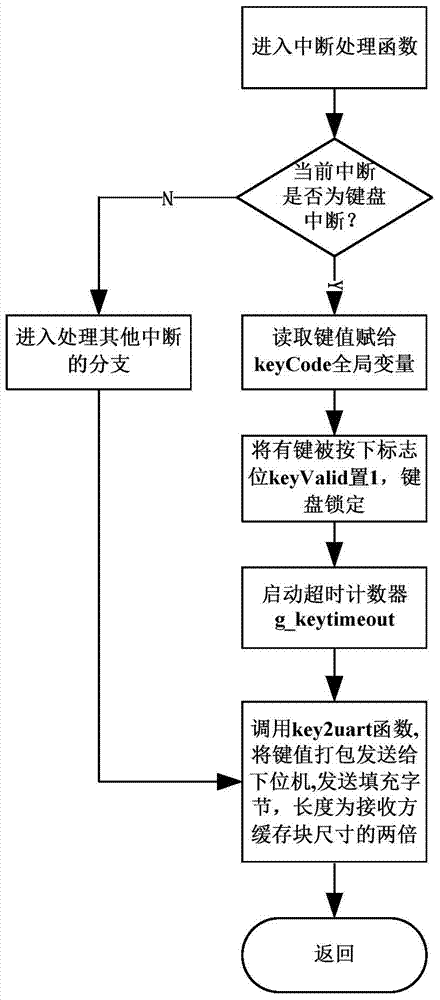

[0058] Such as figure 2 As shown, the present invention realizes the remote control method based on the industrial inkjet printer as follows: adding the same upper computer hardware as the lower computer, and selecting the remote control circuit as required; transplanting the interface communication protocol to the upper and lower computers respectively, and keeping the lower computer The upper layer interface of the computer program remains unchanged; according to the designed data packet protocol and data transmission and receiving program flow, the double-ended sending and receiving program is realized.

[0059] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0060] In the embedded control system, its main chip can support common interface chip expansion. Therefore, in this embodiment, the hardware adopts the structure of a CPU motherboard plus a peripheral motherboard, and the remote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com