Titanium steel composite elevator traction sheave and production method thereof

A production method, elevator traction technology, applied to elevators in buildings, transportation and packaging, etc., can solve the problems of low traction force of semi-circular groove traction sheaves, high limitations of V-shaped groove traction sheaves, etc., and achieve light weight , small deformation, good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

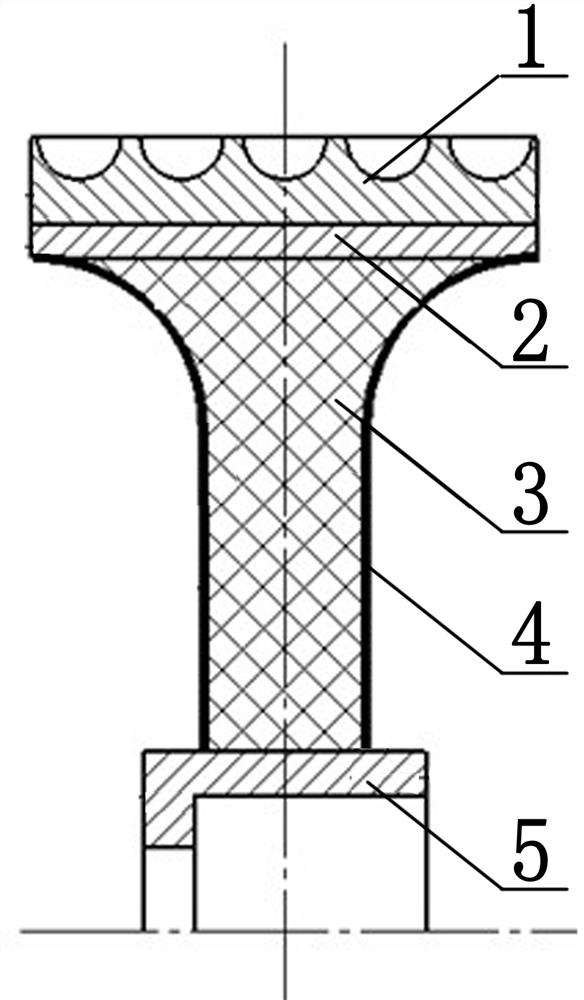

[0028] according to figure 1 The structure and production method of the present invention are described in detail. The titanium-steel composite elevator traction sheave includes a wheel rim with a traction rope groove, a wheel spoke, a shaft sleeve and the like. Wherein, the rim is a titanium-steel composite structure, the traction rope groove is arranged on the outer side of the titanium alloy layer 1 of the rim, and the rim is welded to the spokes through the carbon steel layer 2 of the rim. The spoke is a sandwich structure consisting of spoke carbon steel layer 2-spoke foam aluminum layer 4-spoke carbon steel layer 2, and the axle sleeve 5 is welded to the spoke. The traction rope groove can be processed into a semicircular groove or a concave groove or a V-shaped groove.

[0029] The production method of the titanium-steel composite elevator traction sheave comprises the following steps:

[0030] 1) Preparation of titanium-steel composite pipes and low-carbon steel Q23...

Embodiment 2

[0042] In step ②, the thickness ratio of the titanium tube blank layer to the short steel tube layer is 5:3, and other steps are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com