Thermal treatment process of elastic chains

A kind of process and elastic chain technology, which is applied in the field of elastic chain heat treatment process, can solve the problems of material waste, affect product production, and fail to guarantee the pass rate, etc., and achieve the effects of reducing tissue stress, improving mechanical performance indicators, and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] An elastic chain heat treatment process, comprising the following steps:

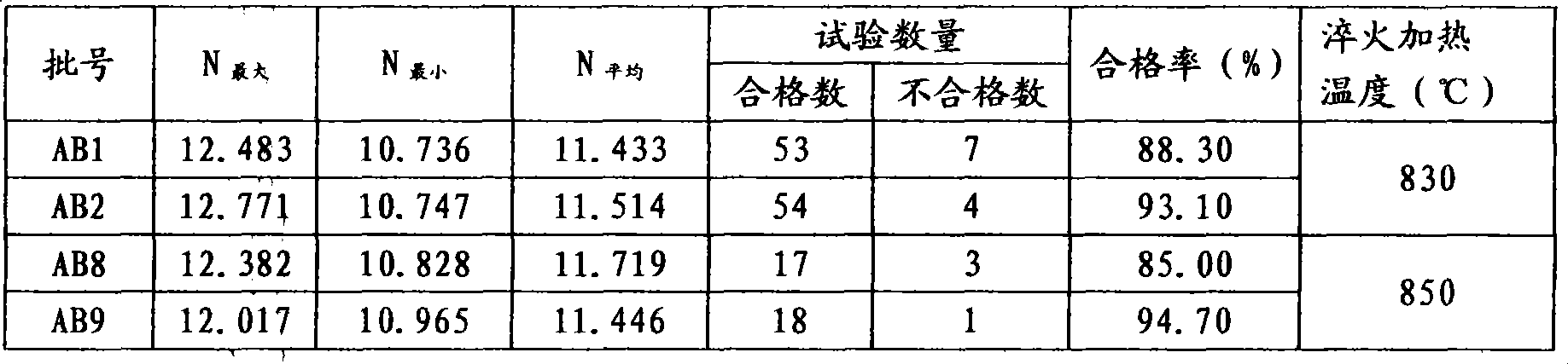

[0027] Use a salt furnace to heat the workpiece to 840°C to austenitize and homogenize it;

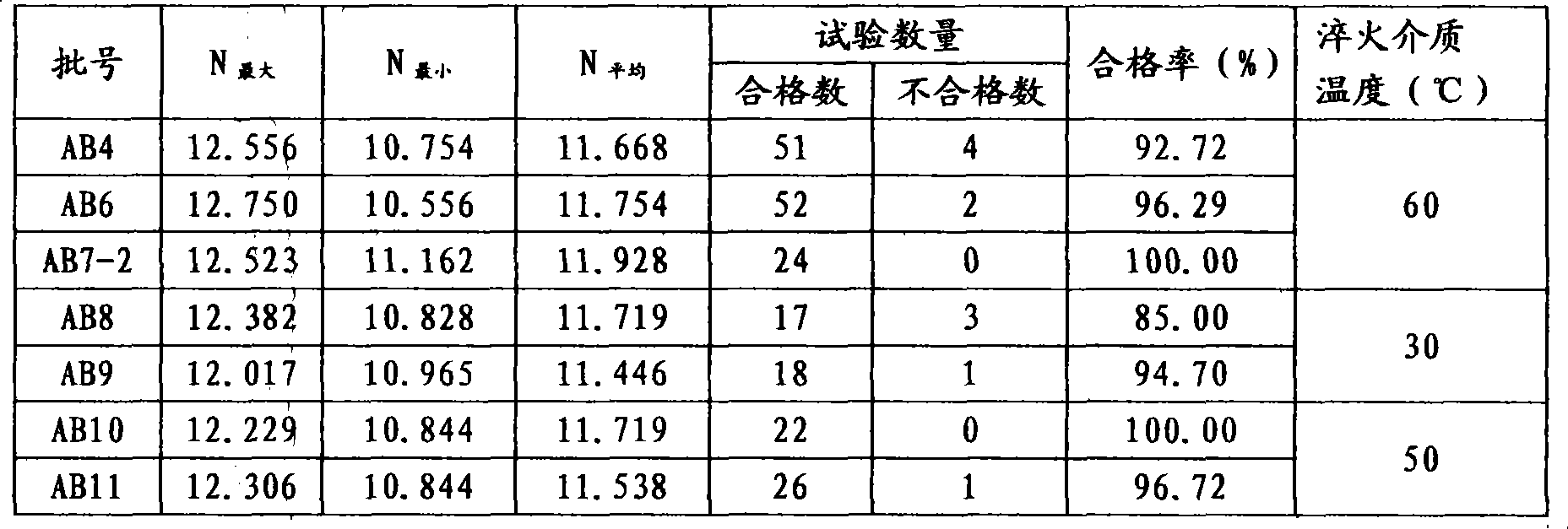

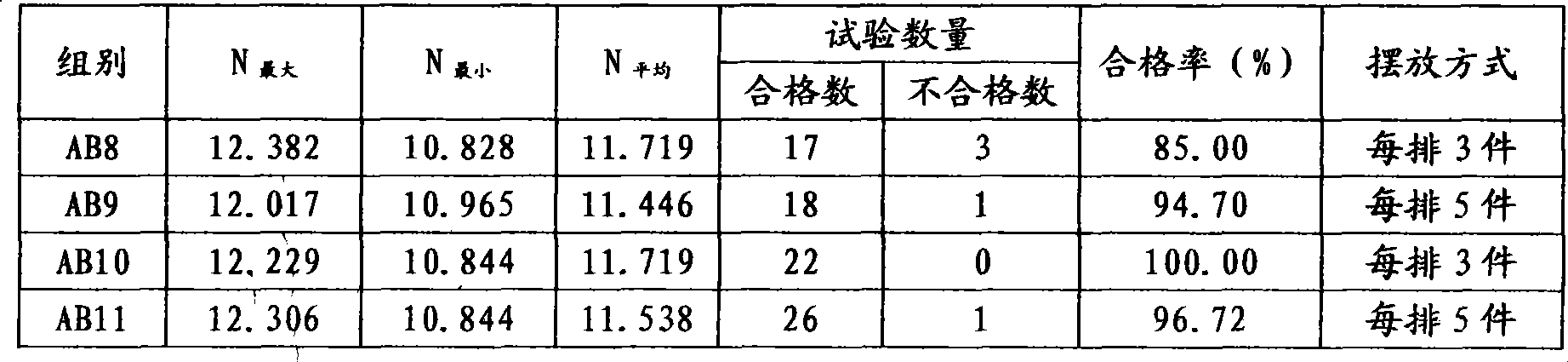

[0028] Cool to 240°C in a nitrate tank, keep isothermal for 6 minutes and then transfer to water cooling;

[0029] It also includes a tempering step: using a nitrate furnace to heat to 320 ° C, and then transferring to water cooling.

Embodiment 2

[0031] An elastic chain heat treatment process, comprising the following steps:

[0032] Use a salt furnace to heat the workpiece to 860°C to austenitize and homogenize it;

[0033] Cool to 260°C in a nitrate tank, keep isothermal for 6 minutes and then transfer to water cooling;

[0034] It also includes a tempering step: use a nitrate furnace to heat to 360 ° C, and then transfer to water cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com