Dedicated wire brush for snow removal truck, as well as production equipment and production method of dedicated wire brush

A snow sweeper and wire brushing technology, which is applied in the directions of melt spinning, rayon manufacturing, filament/thread forming, etc., can solve the problems of affecting the cleaning effect, increase the cost of use, easy to break, etc., and achieve good cleaning effect and use. Long life, improved strength and toughness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

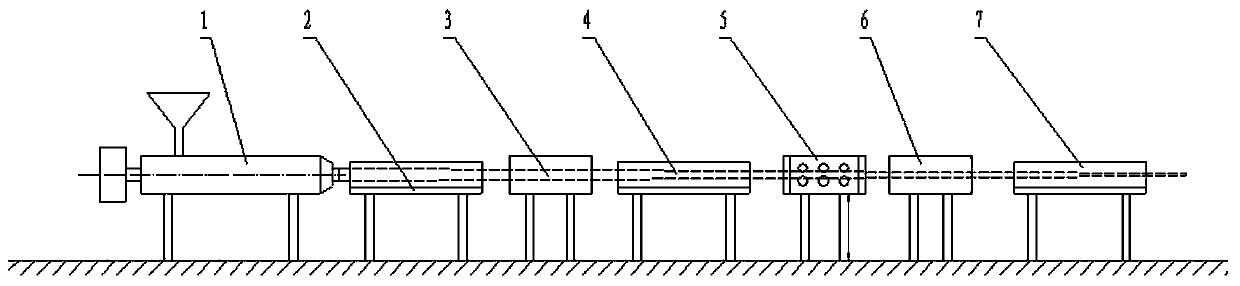

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

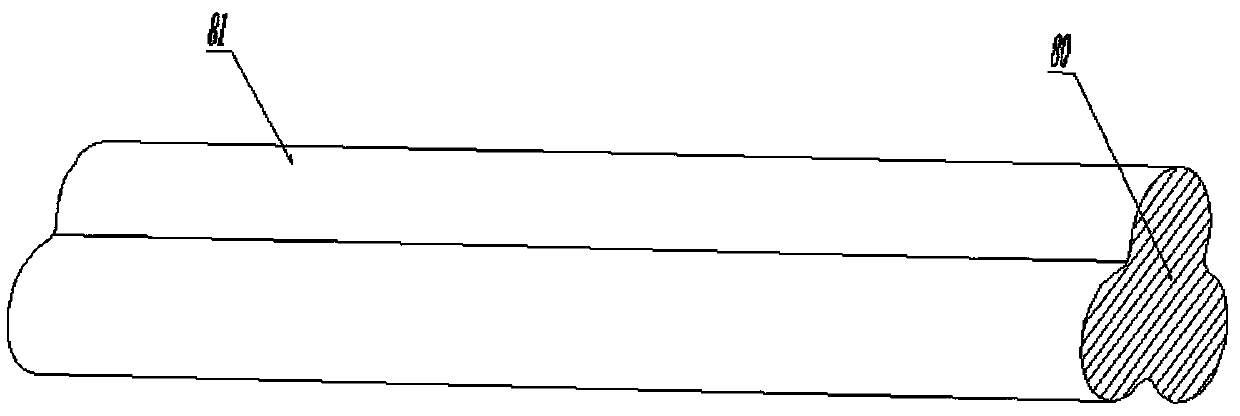

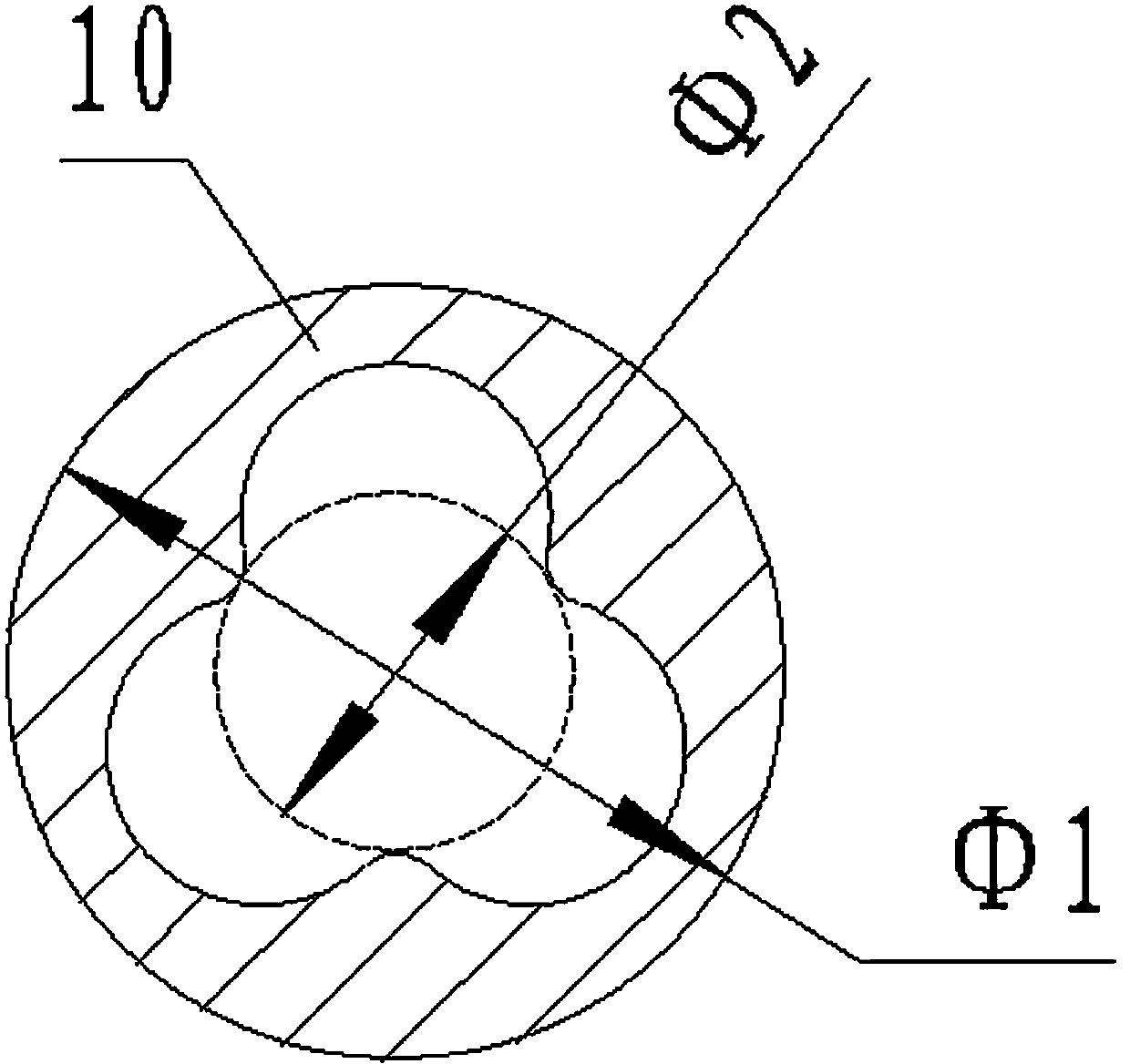

[0016] Such as figure 1 , figure 2 It can be seen that the special brush filament for snowplow of the present invention is composed of 90% pp and 10% wire drawing agent by weight; its structure includes a body 80 and three flanges 81 uniformly distributed along the outer surface of the body 80 , on the cross-section of the brush filament, the ratio of the diameter of the outer circle formed by the farthest points of the three flanges 81 to the diameter of the inner circle formed by the closest points is: Φ1:Φ2=2:1.

[0017] The main body 80 and the three flanges 81 of the special brush filament for snow plows are arranged in parallel along the length direction of the brush filament, and the main body 80 and the three flanges 81 are integrally extruded.

[0018] The outer edges of the three flanges 81 are circular, and along the cross-section of the brush filaments, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com