Foundation backfill reinforcement method

A technology of backfilling soil and foundation, which is applied in soil protection, infrastructure engineering, construction, etc., and can solve problems such as lack of settlement time and surface layer subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

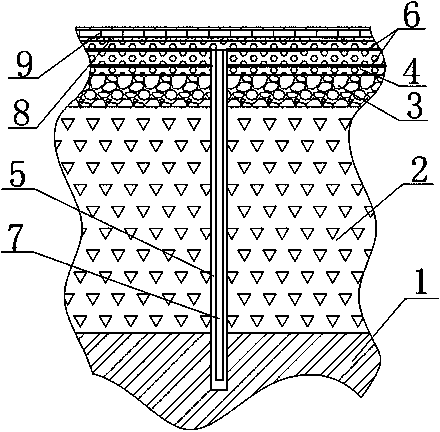

[0020] Such as figure 1 As shown in the present invention, a reinforcement method of foundation backfill soil is laid with a backfill soil layer 2 on the base soil layer 1, and a cushion layer 3 is laid on the backfill soil layer 2, and the cushion layer 3 is composed of graded sand and gravel , the maximum particle size is less than 3.0cm, the mud content is less than 5%, and its thickness is 15cm to 25cm. A reinforced concrete slab 4 is arranged on the cushion layer 3, and the thickness of the reinforced concrete slab 4 is generally not less than 30cm. There are two layers of steel mesh 6 in the reinforced concrete slab 4, the diameter of the steel bar is not less than Ф14, the filling material is C25 concrete, and the grouting column 5 extending downward from the reinforced concrete slab 4 to the base soil layer 1 is set, and the grouting column 5 It is cylindrical, and a grouting steel pipe 7 is installed inside it. After drilling the hole to at least 2 meters below the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com