A Construction Method for Grooving Unit Groove Section of "h" Type Anti-scouring Wall

A technology of trough construction and unit trough, which is applied in artificial islands, water conservancy projects, infrastructure engineering, etc., can solve the problems of prone to grout leakage, complex structure, complex construction technology, etc., and achieve the effect of avoiding grout leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

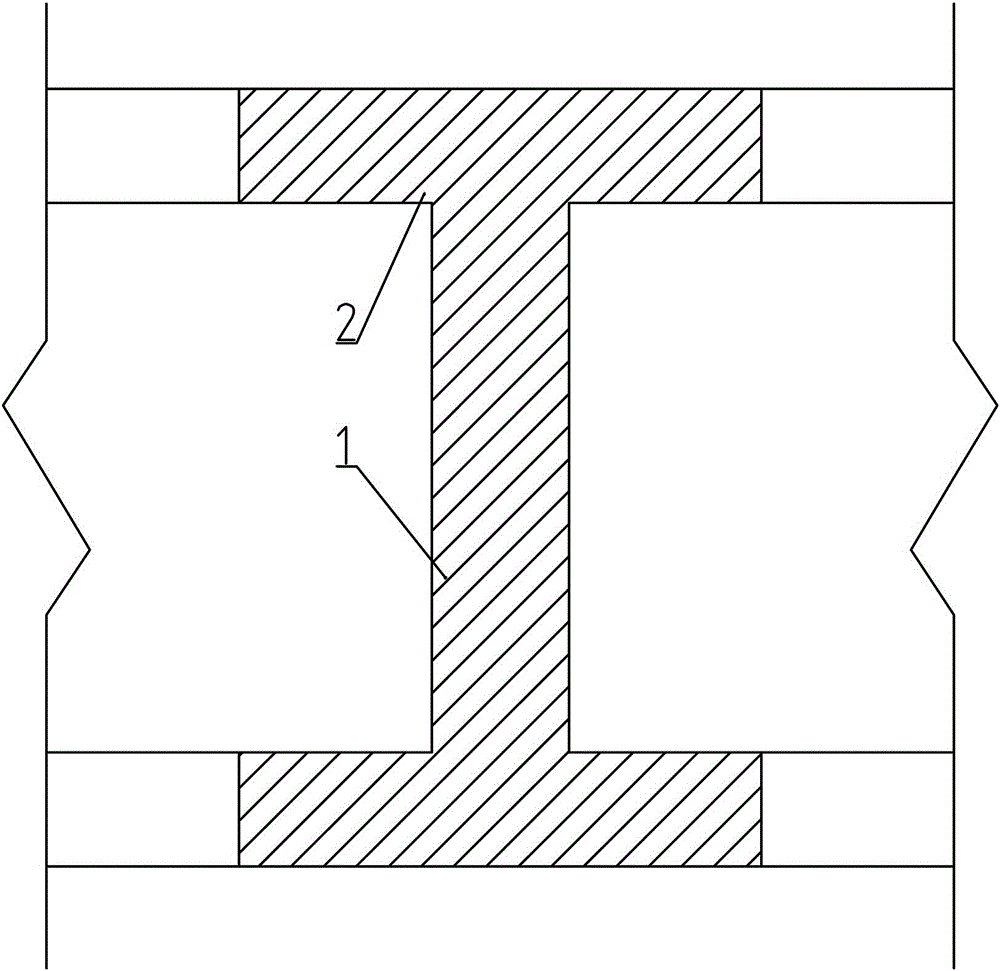

[0019] like figure 1 , 2 As shown in , a construction method for forming grooves of "H" type anti-scouring wall unit groove section, "H" type anti-scouring wall unit groove section is composed of web 1 and wing plates 2 located at both ends of web 1, including the following steps :

[0020] Construction preparation:

[0021] Including guide wall construction, hydropower system formation, mud preparation, grab bucket placement, etc.;

[0022] Use the grab bucket to dig and construct the "H" type anti-scouring wall unit groove section. With this step, compared with the impact drilling machine, the groove can be formed quickly, and the occurrence of slurry leakage and collapse accidents can be avoided.

Embodiment 2

[0024] On the basis of embodiment 1, in the preferred scheme, the grab construction is carried out according to the following steps:

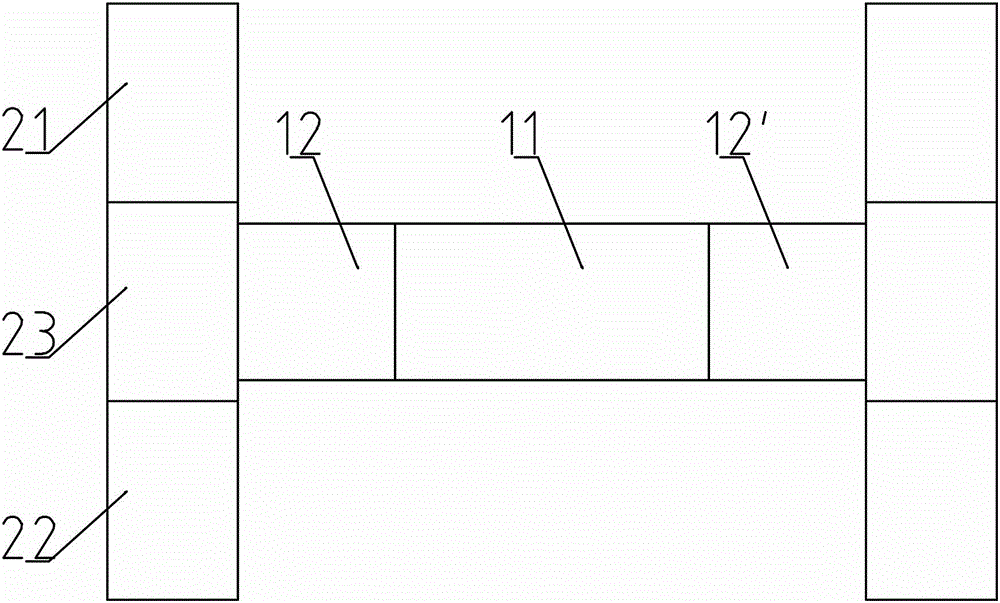

[0025] 1. The grab first grabs and digs the web main hole 11 located in the middle of the web 1; through this step, the web main hole 11 is constructed first to avoid interference with other subsequent holes.

[0026] 2. Grab the first hole 21 of the wing plate and the second hole 22 of the wing plate located at both ends of the wing plate 2 by the grab bucket, and then grab the third hole 23 of the wing plate located in the middle of the wing plate 2 by the grab bucket; The collapsed hole of the plate 2 reduces the rolling of the peripheral platform of the wing plate 2.

[0027] 3. The grab grabs and digs the web auxiliary holes 12 and 12' located at both ends of the web 1; here the web auxiliary holes 12 and 12' are in an isolated position, and the grab is located on the outer edge of the wing 2, which is also convenient for construction , I...

Embodiment 3

[0030] On the basis of Example 2, such as figure 2 As shown in , first use a grab bucket to grab and dig the main hole 11 to the end hole of the web;

[0031] Then two grabs are used to grab and dig the wing plate 2 to the end hole at the same time, and the grabs are arranged on both sides of the wing wall, one for each, walking parallel to the axis of the wing wall. When catching and digging, first grasp the main hole on both sides of the wing wall, namely the first hole 21 of the wing plate and the third hole 23 of the wing plate, and then grab the secondary hole in the middle of the wing wall, which is the second hole 22 of the wing plate.

[0032] Finally, a grab bucket is used to grab and dig the auxiliary holes 12 and 12' of the web to the end hole to complete the task of grabbing and digging the web.

[0033] Using two grab buckets to grab and dig the wing 2 at the same time further speeds up the construction progress of the groove section of the "H" type anti-scourin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com