Marble hammering and grooving device

A marble and mobile seat technology, applied in transmissions, stone processing tools, stone processing equipment, etc., can solve the problems of high physical exertion and stone bullets shot to the staff, so as to reduce consumption, improve work efficiency, and improve openness. The effect of slot speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

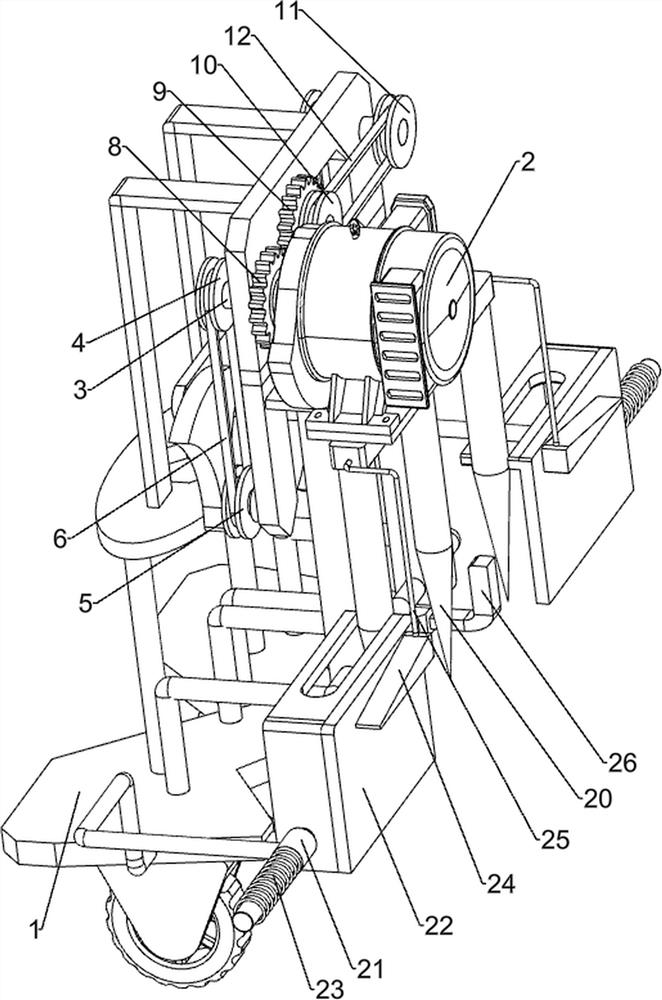

[0021] A device for hammering open grooves in marble, such as Figure 1-4 As shown, it includes a moving seat 1, a driving assembly, a transmission assembly and a slotting assembly. The moving seat 1 is used to install the whole device. As for the transmission assembly of the transmission, the lower part of the moving seat 1 is provided with a slotting assembly for slotting by sliding.

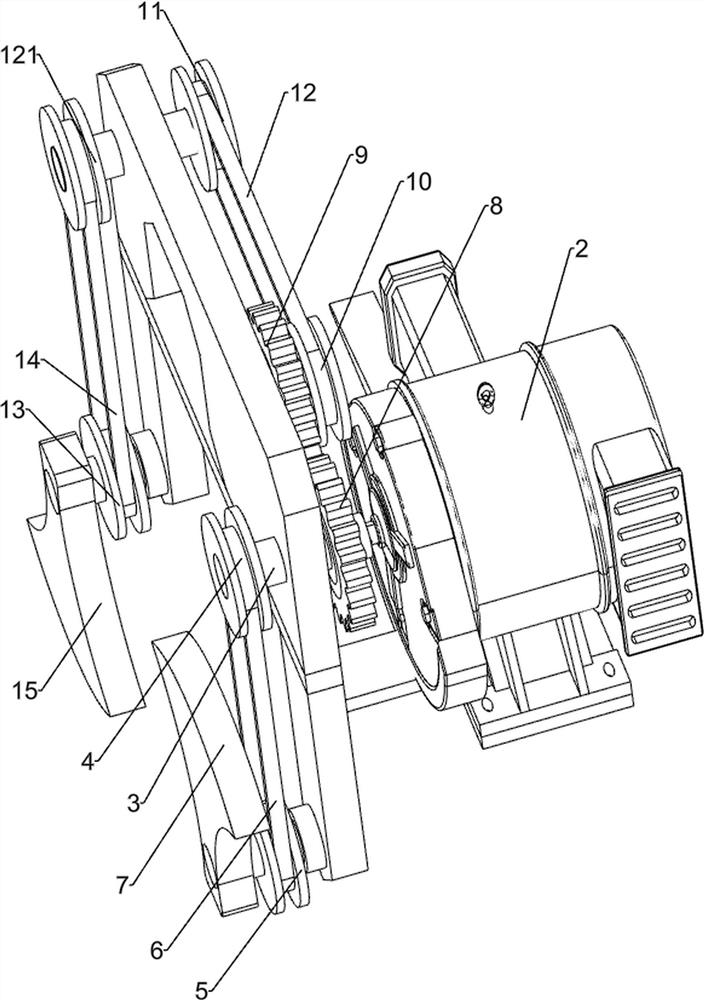

[0022] Such as Figure 1-3 As shown, the driving assembly includes a reduction motor 2, a rotating rod 3, a first pulley 4, a second pulley 5, a first flat belt 6 and a first push plate 7, and the rear side of the upper part of the moving seat 1 is fixed with a reduction motor through bolts. 2. The output shaft of the geared motor 2 is provided with a rotating rod 3, the front end of the rotating rod 3 is provided with a first pulley 4, and the middle part of the moving seat 1 is rotated on the right side with a second pulley 5, and the second pulley 5 is connected with the first pulley 4. A...

Embodiment 2

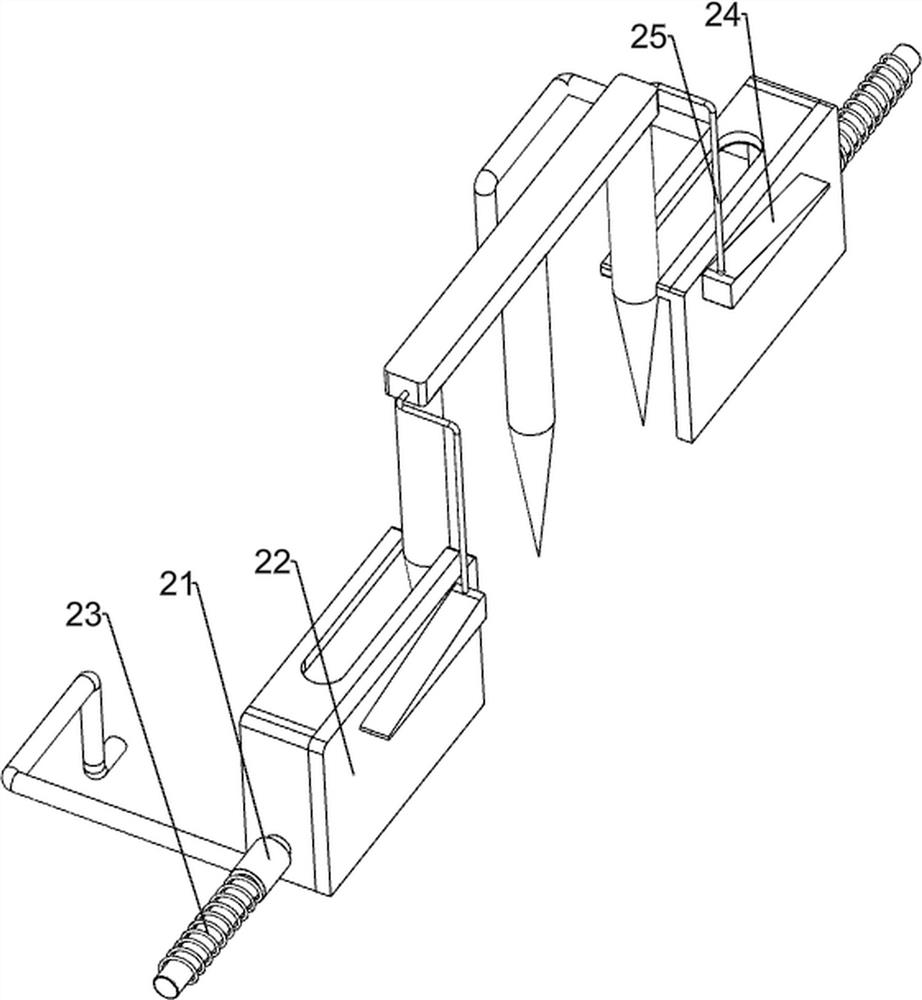

[0030] On the basis of above-mentioned embodiment 1, as figure 1 , 2 Shown in and 5, also include sliding sleeve 21, block frame 22, second spring 23, wedge block 24 and L-shaped bar 25, all left and right sides of mobile base 1 bottom are fixed with sliding sleeve 21 by screw, sliding sleeve 21 The inner sliding type is provided with a shielding frame 22, the shielding frame 22 cooperates with each other, the second spring 23 is connected between the shielding frame 22 and the sliding sleeve 21, and the rear side of the shielding frame 22 is fixed with a wedge block 24 and an awl 20 by bolts. The left and right sides are all connected with L-shaped rods 25, and the L-shaped rods 25 cooperate with the wedge-shaped blocks 24.

[0031] On the basis of above-mentioned embodiment 1, as figure 1 with 2 As shown, a limiting plate 26 is also included, and the rear side of the moving seat 1 is welded with a limiting plate 26, and there are three limiting plates 26.

[0032]The spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com