Slotting machine for pulling rods of evacuation platform of subway and machining method

A technology of evacuation platform and slotting machine, which is applied in the field of auxiliary equipment for subways, can solve the problems of poor composite material platform plate, etc., and achieve the effects of good slotting quality, adjustable slotting depth and high slotting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are used to further illustrate the present invention in conjunction with the accompanying drawings and examples, but are not intended to limit the scope of the present invention.

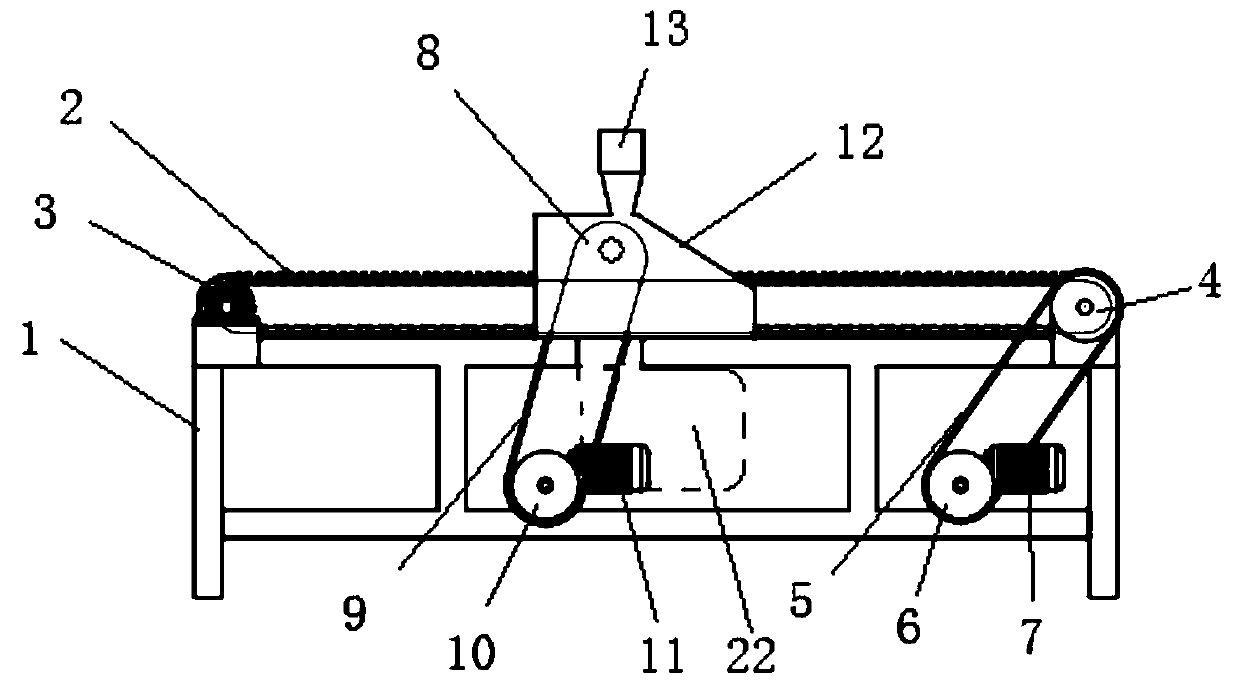

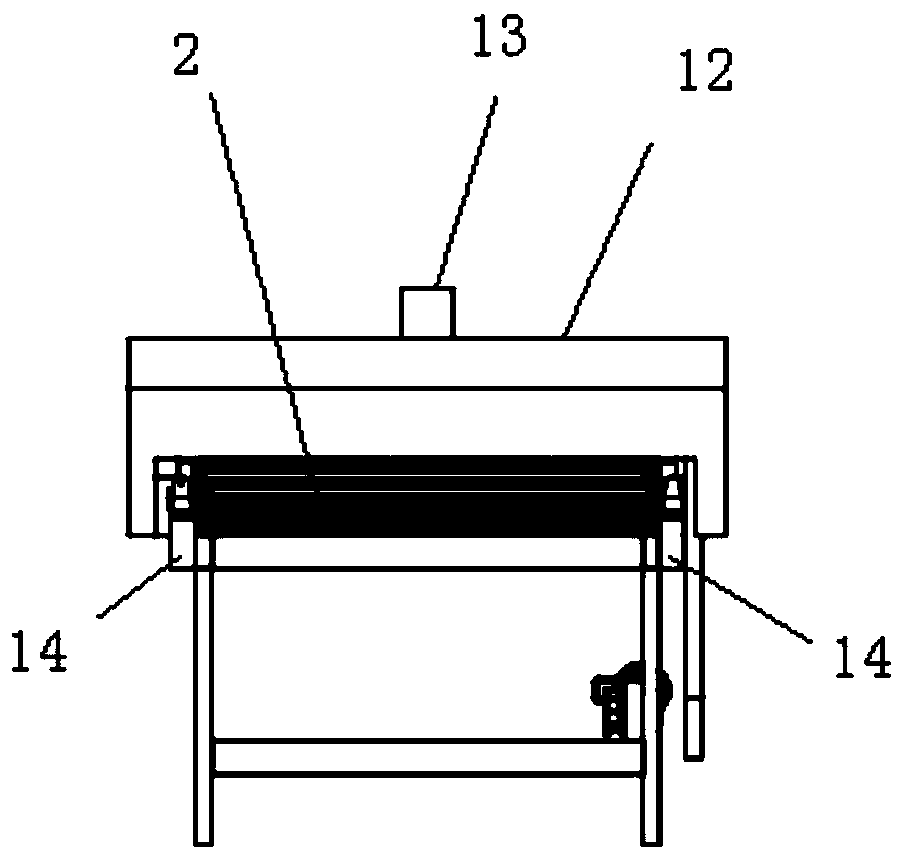

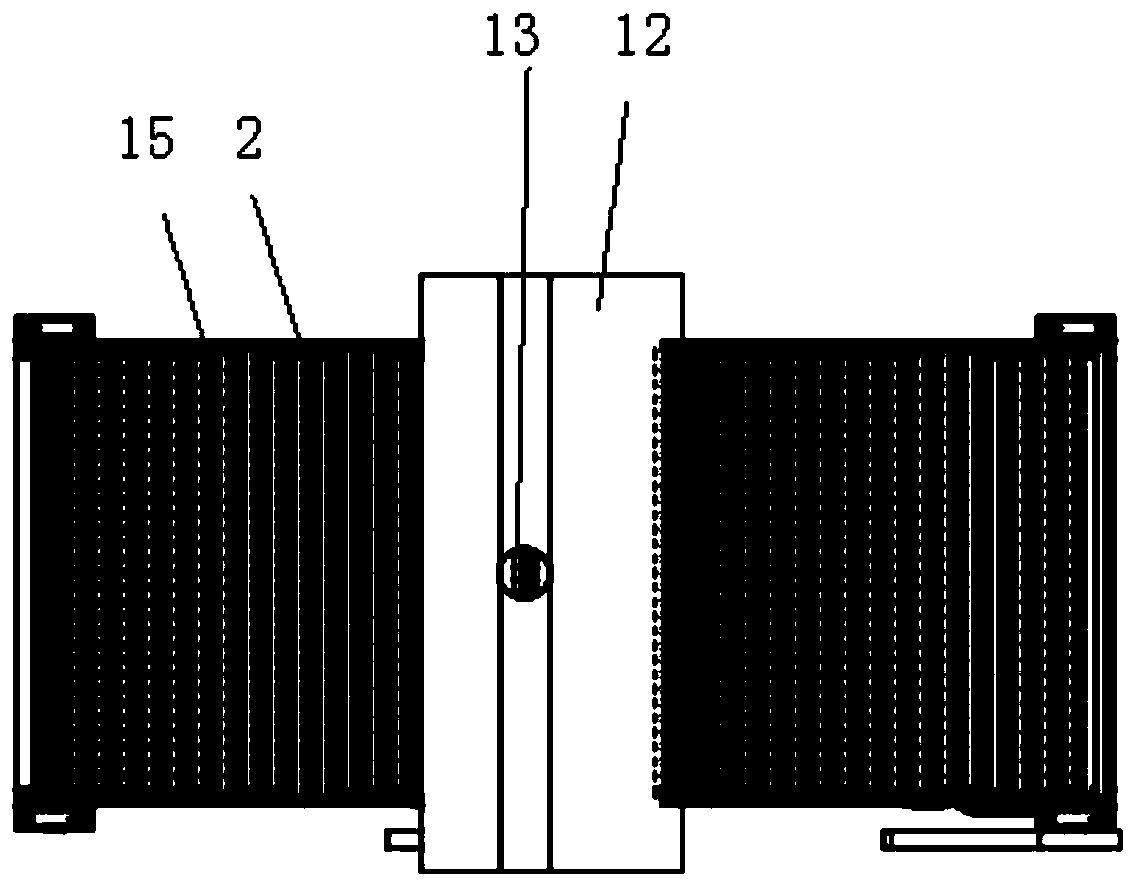

[0030] Such as figure 1 , 2 , shown in 3, 4, 5, 6, 7, a kind of subway evacuation platform pull rod slotting machine comprises: frame 1, chain plate, pull rod clamp, pull rod slotting device, dust removal device, set on the frame 1 There is a chain plate lifting mechanism, the chain plate 2 of the chain plate lifting mechanism is evenly distributed with pull rod clamps, a pull rod slotting device is installed above the chain plate 2, and a dust removal device is installed outside the pull bar slotting device and the chain plate 2 below; The plate power device and the cutter power device are connected with the electric control device through cables.

[0031] The chain plate 2 is connected to the sprockets 3 at both ends through the chains on both sides; the rotating shafts of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com