Automatic lock

A technology of automatic lock and lock shell, applied in the field of automatic lock, can solve the problems of complex structure of automatic lock and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

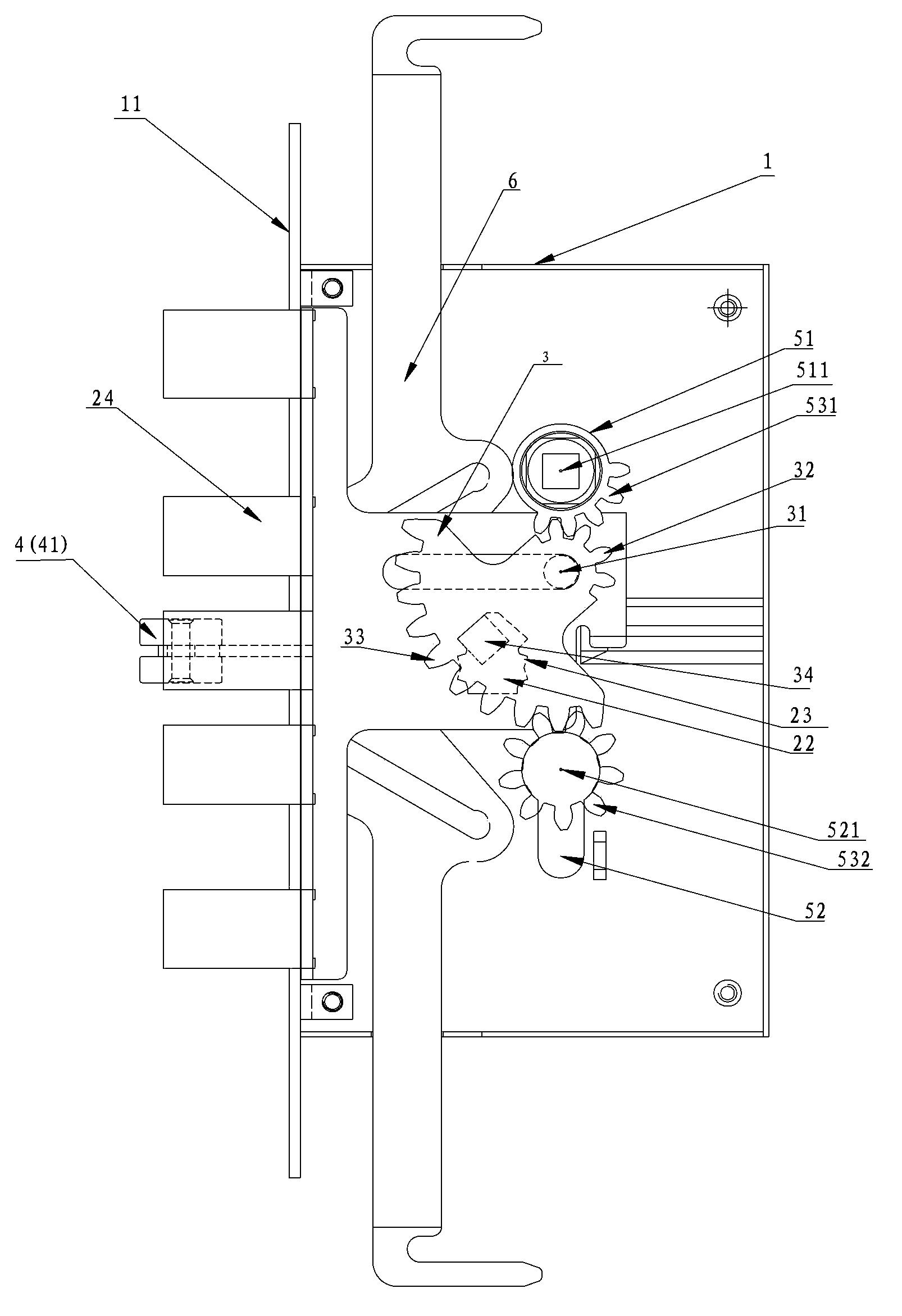

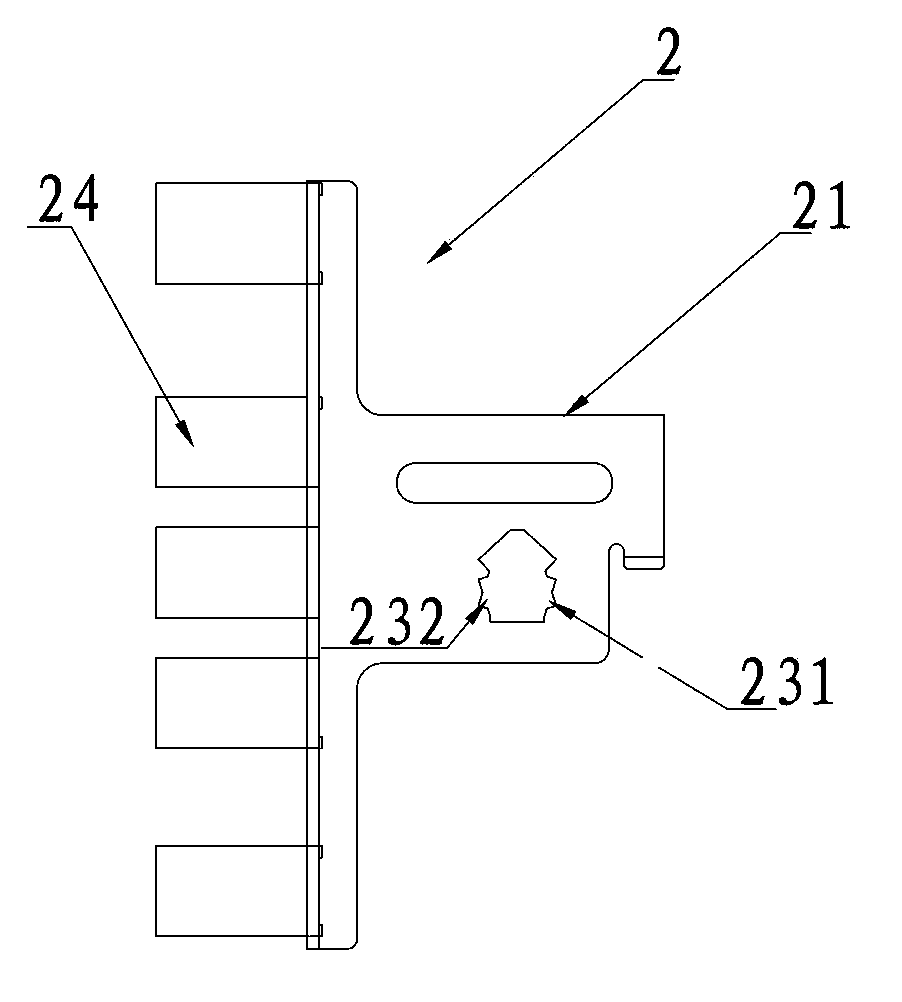

[0109] Figure 1-5 Shown is the implementation of the automatic lock described in this embodiment, including a lock case 1, a bolt member 2, a swing member 3 and a trigger assembly 4;

[0110] The lock tongue member 2 is arranged in the lock housing 1, and is limited to slide reciprocally between the lock-out terminal position and the lock-in terminal position along the lock-out direction A. In this embodiment, the lock tongue member 2 includes On the deadbolt plate 21 where the deadbolt 24 is installed, a traction groove 22 is formed on the deadbolt plate 21, and the edge of the traction groove 22 suitable for the action of the conflicting portion 34 is a guiding edge;

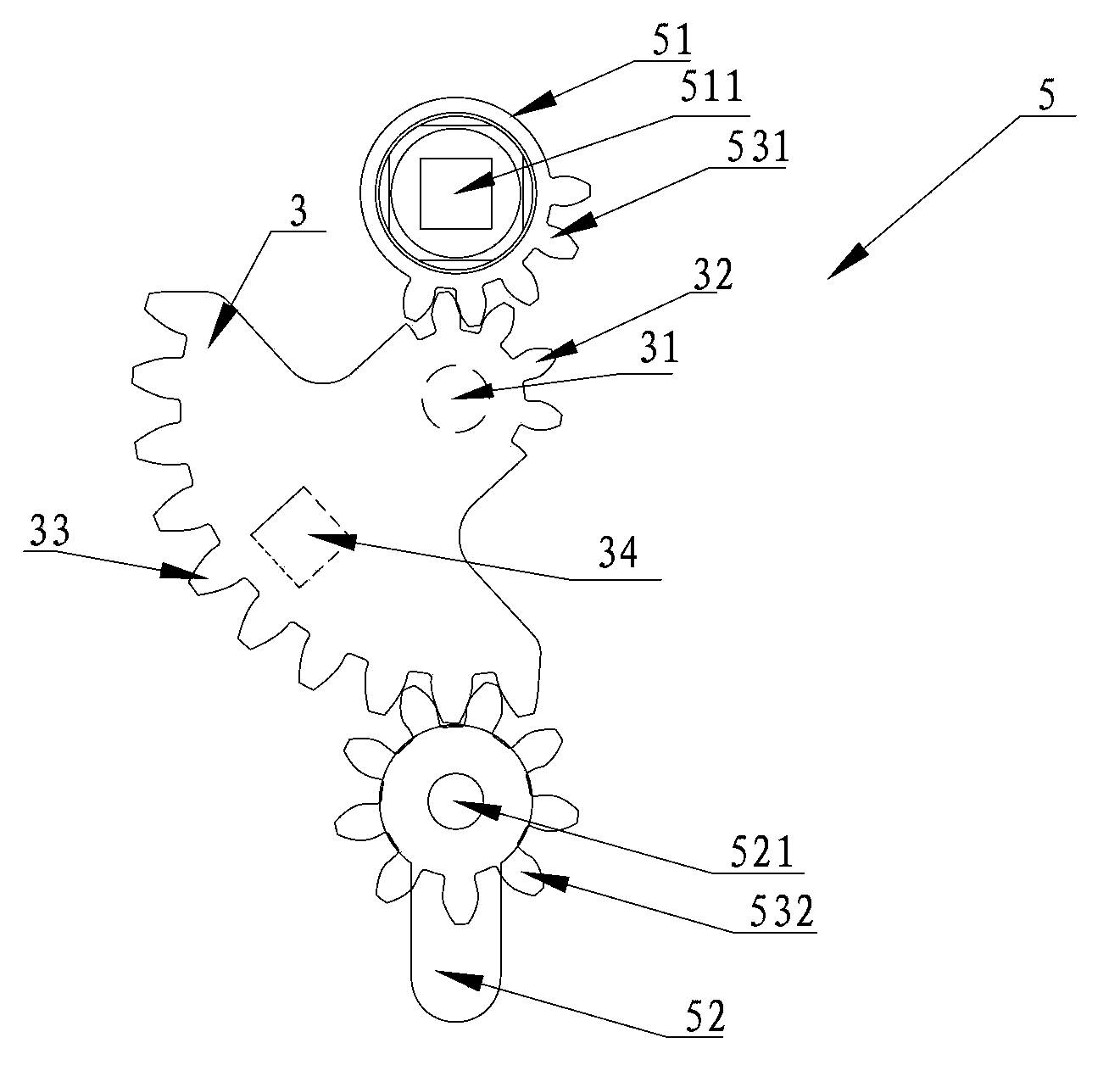

[0111] The swing member 3 is arranged in the lock case 1 and is rotatably mounted on the lock case 1; driven by the operating mechanism 5 to rotate around a fixed swing axis 31; between the operating mechanism 5 and the A transmission mechanism is provided between the swinging members 3, and the transmission...

Embodiment 2

[0123] Figure 6 Shown is the automatic lock described in this embodiment, including a lock case 1, a bolt member 2, a swing member 3 and a trigger assembly 4;

[0124] The lock tongue member 2 is arranged in the lock housing 1, and is limited to slide reciprocally between the lock-out terminal position and the lock-in terminal position along the lock-out direction A. In this embodiment, the lock tongue member 2 includes On the deadbolt plate 21 where the deadbolt 2 is installed, a traction groove 22 is formed on the deadbolt plate 21, and the edge of the traction groove 22 that is suitable for the action of the conflicting portion 34 is a guiding edge;

[0125] The swing member 3 is arranged in the lock case 1 and is rotatably mounted on the lock case 1; driven by the operating mechanism 5 to rotate around a fixed swing axis 31; between the operating mechanism 5 and the A transmission mechanism is provided between the swinging members 3, and the transmission mechanism includ...

Embodiment 3

[0150] Figure 17-18 Shown is the implementation of the automatic lock described in this embodiment, which includes a lock case 1, a bolt member 2, a swing member 3 and a trigger assembly 4;

[0151] The lock tongue member 2 is arranged in the lock housing 1, and is limited to slide reciprocally between the lock-out terminal position and the lock-in terminal position along the lock-out direction A. In this embodiment, the lock tongue member 2 includes On the deadbolt plate 21 where the deadbolt 24 is installed, a traction groove 22 is formed on the deadbolt plate 21, and the edge of the traction groove 22 suitable for the action of the conflicting portion 34 is a guiding edge;

[0152] The swing member 3 is arranged in the lock case 1 and is rotatably mounted on the lock case 1; driven by the operating mechanism 5, it rotates around a fixed swing shaft 31, preferably the swing shaft 31 is arranged on the The locking part 23 is located between the position of the lock-out term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com