Solar photovoltaic glass window and manufacturing method thereof

A solar photovoltaic and glass window technology, applied in the field of glass windows, can solve the problems of expensive production cost, complex structure design, lack of light transmission function, etc., and achieve the effects of easy acquisition, simple operation, and improved energy conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

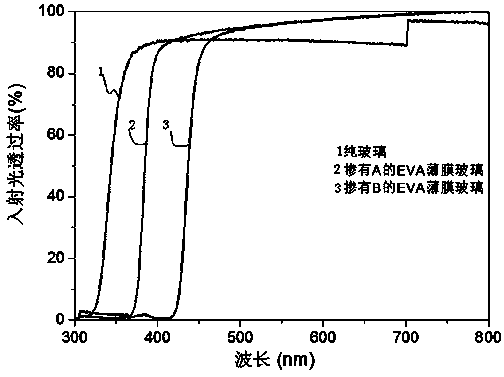

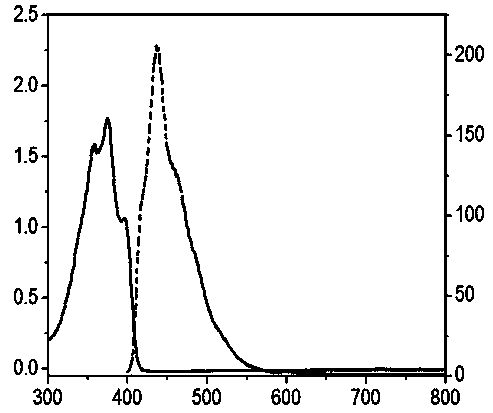

[0026] Example 1, this example prepares a transparent EVA adhesive film for solar cells with light conversion properties. The specific steps and conditions are:

[0027] Weigh 1 g of organic fluorescent dye, stir and dissolve in 1 L of dichloromethane. Take a commercial EVA film with a thickness of 0.5 mm, and cut it into a shape of 20 cm long and 20 cm wide. Then apply the film at 25 o Soak in the above solution at C and time it, take it out after 300 seconds, and let it dry naturally. Take two clean glass plates of the same size, place the finished film between the two glass plates, align them and put them in a vacuum drying oven, press the glass plates evenly with a heavy object, and vacuum for 3-4min, then Raise the temperature to 120°C, keep it warm for 2 minutes, continue heating to 135°C, then vent it, take out the glass piece, and cool it down. Afterwards, stick the battery on the side of the polished glass with optical glue and connect the circuit.

Embodiment 2

[0029] In this example, an EVA adhesive film for solar cells that is transparent and has light conversion properties is prepared. The specific steps and conditions are:

[0030] Weigh 1 g of rare earth complexes, sonicate and dissolve in 1 L of dichloromethane. Take the EVA film (thickness 0.5 mm) and cut it into a shape with a length of 20 cm and a width of 20 cm. Then apply the film at 25 o Soak in the above solution at C and time it, take it out after 300 seconds, and let it dry naturally. All the other are described with embodiment 1.

Embodiment 3

[0032] In this example, an EVA adhesive film for solar cells that is transparent and has light conversion properties is prepared. The specific steps and conditions are:

[0033] Weigh 1 g of organic fluorescent dye, stir and dissolve in 1 L of chloroform. Take the EVA film (thickness 0.5 mm) and cut it into a shape with a length of 20 cm and a width of 20 cm. Then apply the film at 25 o Soak in the above solution at C and time it, take it out after 120 seconds, and let it dry naturally.

[0034] All the other are described with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com