A kind of vertical strip roadway excavation method

A vertical, roadway technology, applied in tunnels, earth-moving drilling, mining equipment, etc., can solve the problems of complex process, roadway collapse, roadway excavation difficulty, etc., and achieve the effect of simple and reliable process, fast excavation speed, and reduced transportation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] For a better understanding of the present invention, now in conjunction with the accompanying drawings, from two aspects of force analysis and theoretical calculation, the present invention is described in detail as follows:

[0031] Coal seam vertical strip roadway excavation method of the present invention, it comprises the following steps:

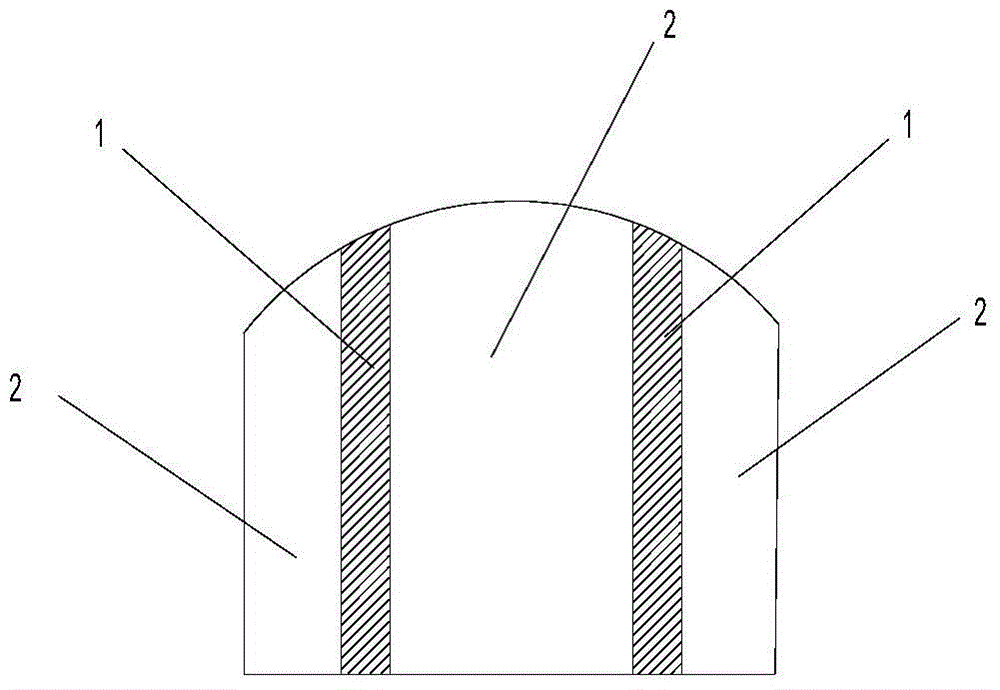

[0032] The first step is to carry out mining of rock formations with a certain width at a certain distance along the vertical direction in the roadway according to the actual geological rock formation properties of the mine. It is an arched upper and lower two-stage structure, the lower section is rectangular and the upper section is arc-shaped. Such as figure 1 as shown, figure 1 Each reference sign in the figure is unmined banded rock pillar 1 and mining area 2 respectively.

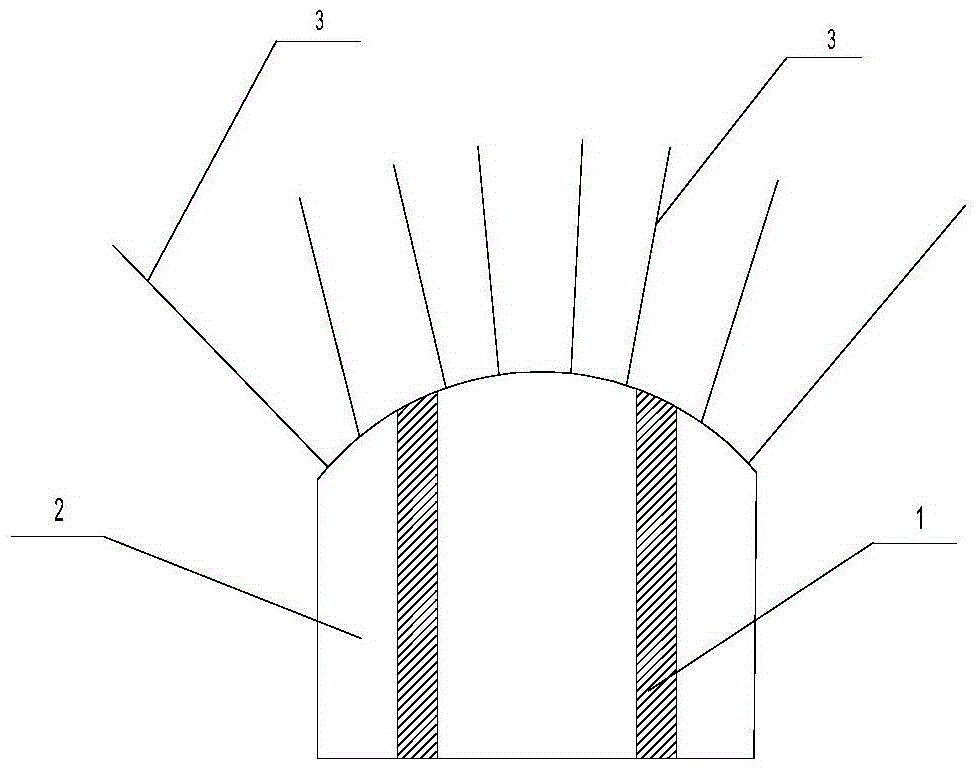

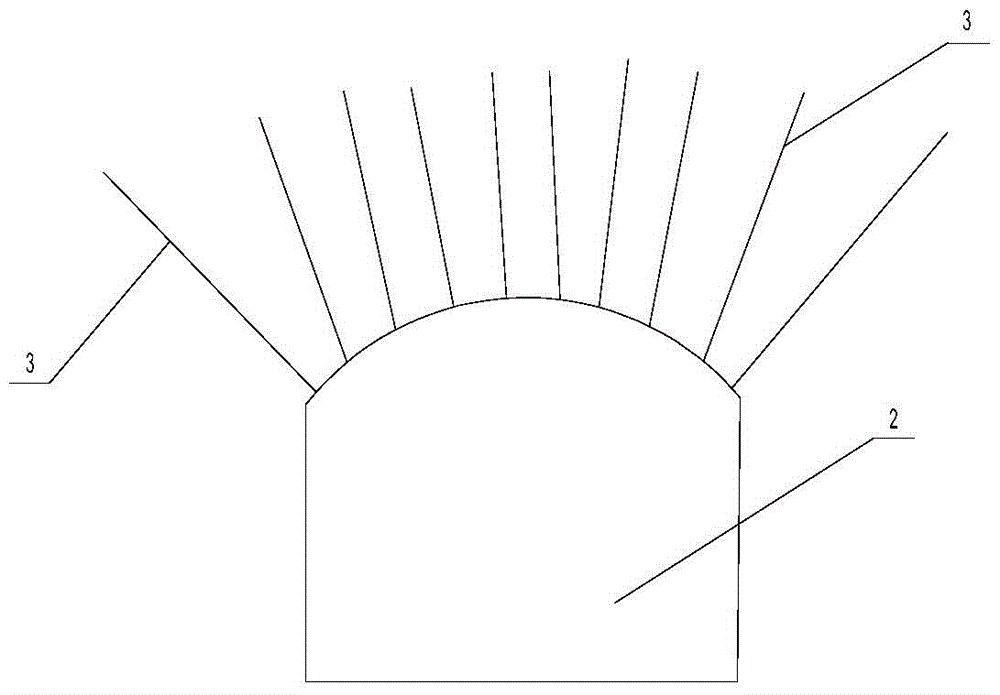

[0033] In the second step, the first drilling is carried out in the space where the rock formation has been mined and the first bolt is installed to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com