compressor

A technology for a compressor and a compression mechanism, applied in the field of compressors, can solve problems such as motor efficiency drop, lubricant temperature drop, compressor performance drop, etc., and achieve the effects of avoiding motor efficiency drop, optimizing cooling path, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following description of preferred embodiments is exemplary only and in no way restricts the invention and its application or usage. The same reference numerals are used to denote the same components in the respective drawings, and thus the configurations of the same components will not be described repeatedly.

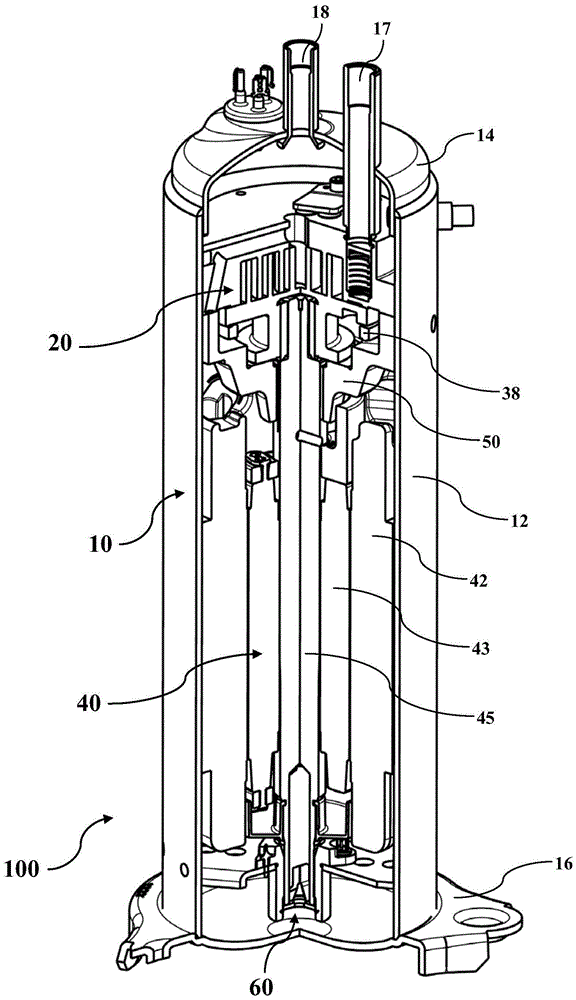

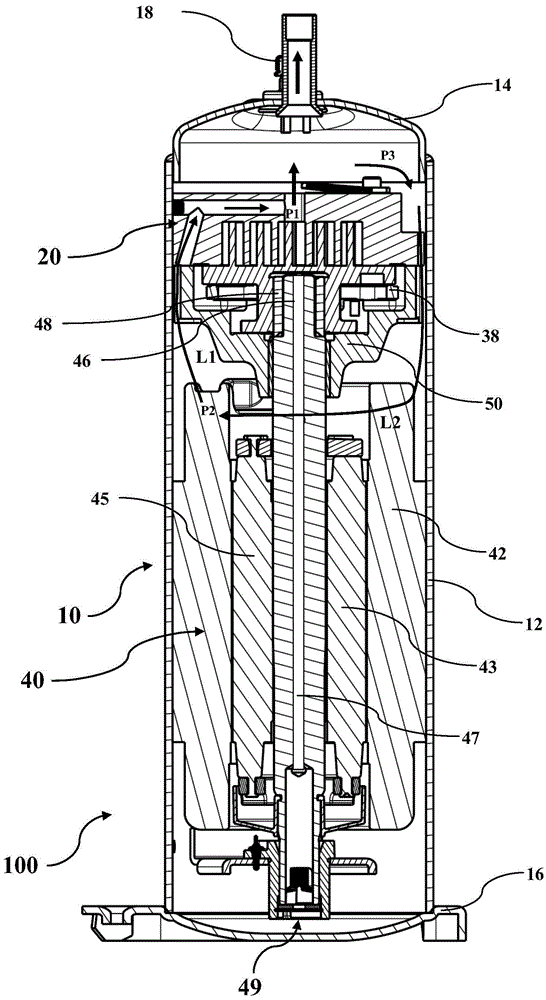

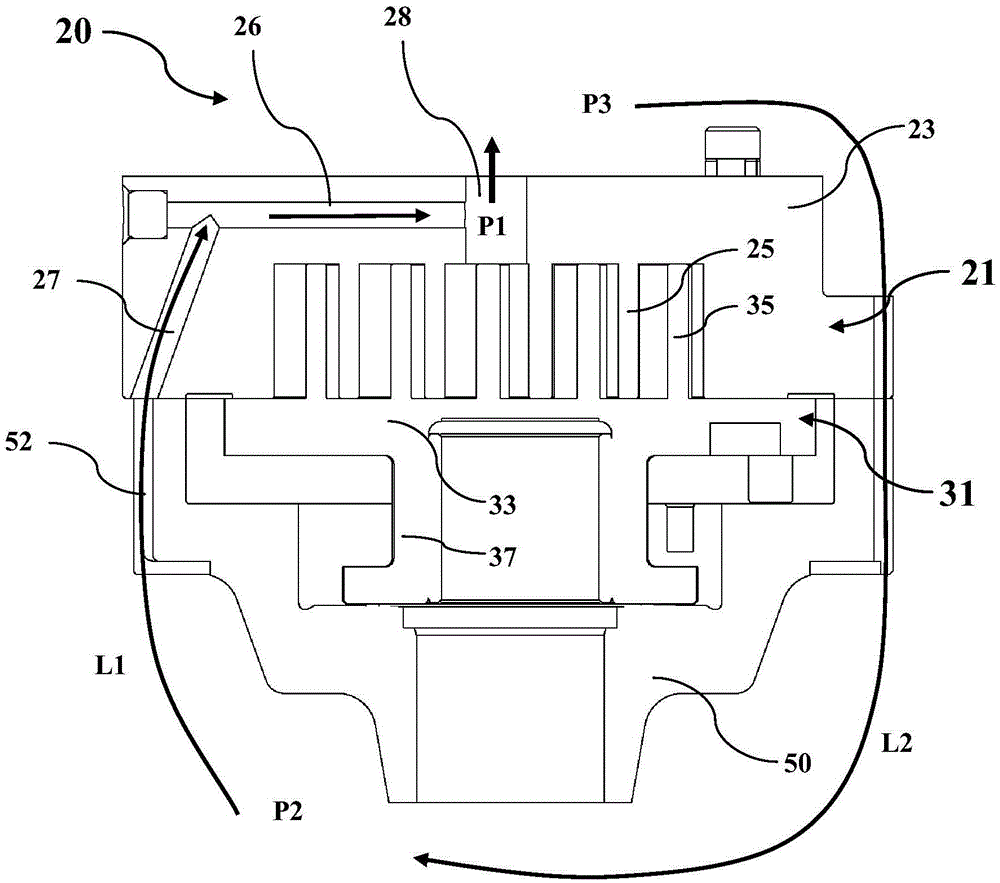

[0027] The following will refer to Figure 1-4 The basic configuration and principle of the compressor 100 according to the first embodiment of the present invention will be described.

[0028] Such as figure 1 and 2 As shown, compressor 100 includes a generally closed housing 10 . The housing 10 defines an inner space of the compressor 100 . In the example in the figures, the housing 10 may be composed of a generally cylindrical body portion 12 , a top cover 14 , and a bottom cover 16 . These parts of the housing 10 can be connected to each other, for example, by bolts or any other suitable method.

[0029] A fluid inlet 17 and a fluid outlet 18 may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com