Continuous lifting pump for pumping unit and lifting method thereof

A technology for pumping units and lifting pumps, which is applied in the field of continuous lifting pumps for pumping units and its lifting, which can solve the problems of eccentric wear, rapid decline in pump efficiency, high energy consumption, etc., to increase the flow area and improve the overall downlink The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

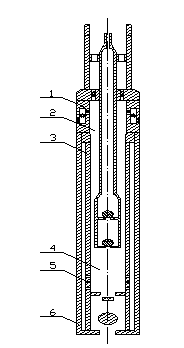

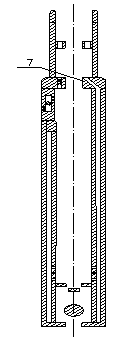

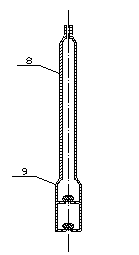

[0029] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0030] according to Figure 1-Figure 5 As shown in the pumping unit continuous lifting pump and its lifting method, a piston 9 with a piston rod 8 and a working cylinder 2 are designed in a cylindrical special pump barrel in the vertical direction, wherein the piston is a hollow piston, and the piston The rod is a hollow piston rod, and the outside of the pump barrel is an outer cylinder 1. There are multiple sets of one-way check valves, three-way two-way check valves, multiple oil passages, and diversion holes installed on the outer cylinder and the cylinder block of the working cylinder; The tubing coupling 6 on the upper part of the barrel is connected to the upper tubing, the tail tube coupling on the lower part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com