Automatic overturning device

A technology that automatically flips and rotates shafts. It is used in power control mechanisms, applications, door/window accessories, etc. It can solve the problems of human body pinch, increase maintenance costs, and heavy motor load, and improve market competitiveness and brand image. Improve the safety performance of use and the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

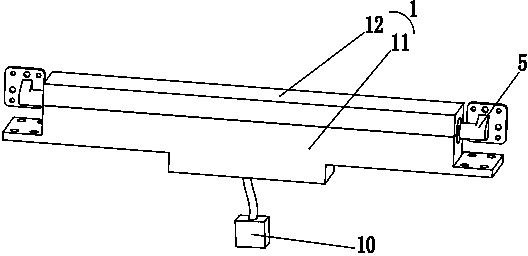

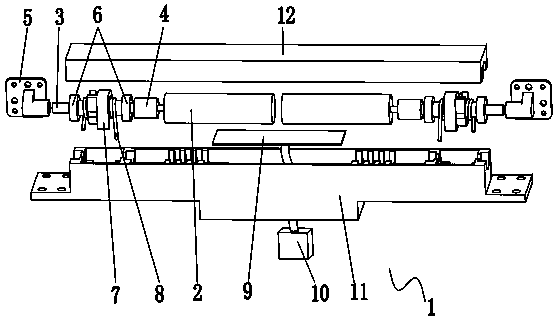

[0014] as attached Figure 1~2 As shown, an automatic turning device includes a housing 1 connected by a base 11 and a cover 12, and a driving mechanism 2 and a rotating shaft 3 are arranged in the housing 1. Here, the driving mechanism selects a motor, and according to the weight of the turning part , choose motors of different power and quantity, and fix the motor in the housing 1 through the base 11 and the cover 12, the housing 1 can prevent dust and water from entering the interior of the housing 1 and reduce the working noise of the motor; the driving mechanism 2 and the rotating shaft 3 are connected together through the connecting sleeve 4, and the connecting piece 5 for installing the flipping part is sleeved at the end of the rotating shaft 3. When the driving mechanism 2 is work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com