Throttle valve for oil gas

A choke valve, oil and gas technology, applied in the direction of lift valve, valve device, wellbore/well valve device, etc., can solve the problems of poor sealing performance, unfavorable on-site maintenance, complex structure of choke valve, etc., to improve the sealing effect , enhance the mechanical properties, enhance the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

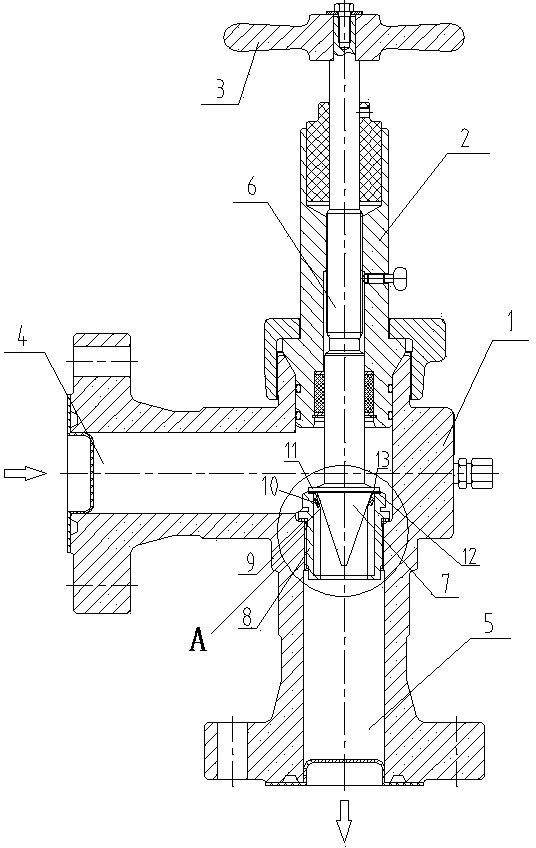

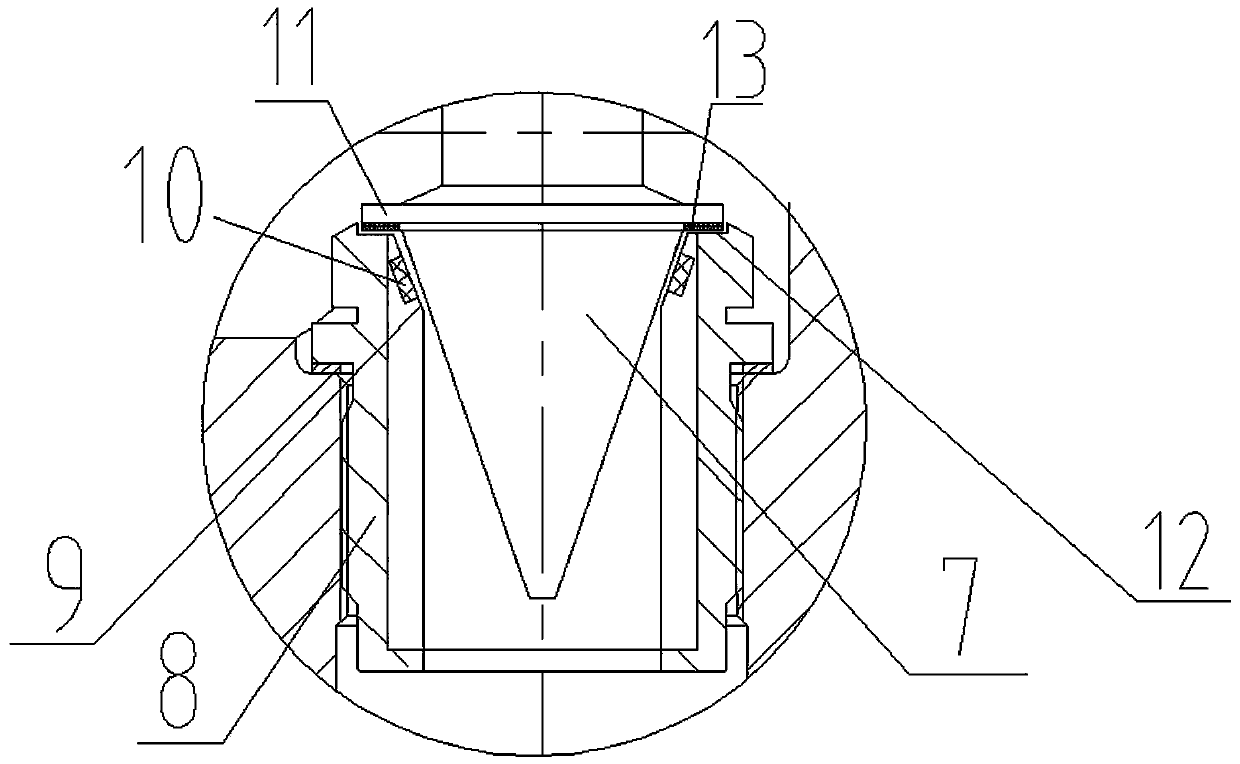

[0020] Such as figure 1 , figure 2 As shown, a throttle valve for oil and gas includes a valve body 1, a valve cover 2, a valve stem 6, a valve core 7, and a valve seat 8. The valve body 1 is provided with a medium inflow channel 4 and a medium outflow channel 5 , the medium inflow channel 4 and the medium outflow channel 5 are vertically arranged, the valve seat 8 is embedded in the medium outflow channel 5, and one end of the valve stem 6 passes through the valve cover 2 and extends to the outside of the valve cover 2 , is connected with the driving handle 3, the other end of the valve stem 6 is connected with the valve core, and the rotation of the driving handle 3 drives the valve stem 6 to rotate, and the valve core 7 and the valve seat 8 are driven by the valve stem 6 to control the flow of the medium. The spool 7 is conical, and the conical spool 7 is inverted to match the valve seat 8. The upper part of the inverted spool 7 protrudes outwards to form a flange 11, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com