Proportion regulation device used for liquid mixing

A liquid mixing and regulating device technology, applied in valve operation/release devices, mixers, valve devices, etc., can solve the problems of fixed structure, inflexible use, inability to increase or decrease the number of liquid outlet pipelines, etc., and achieve simple assembly. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

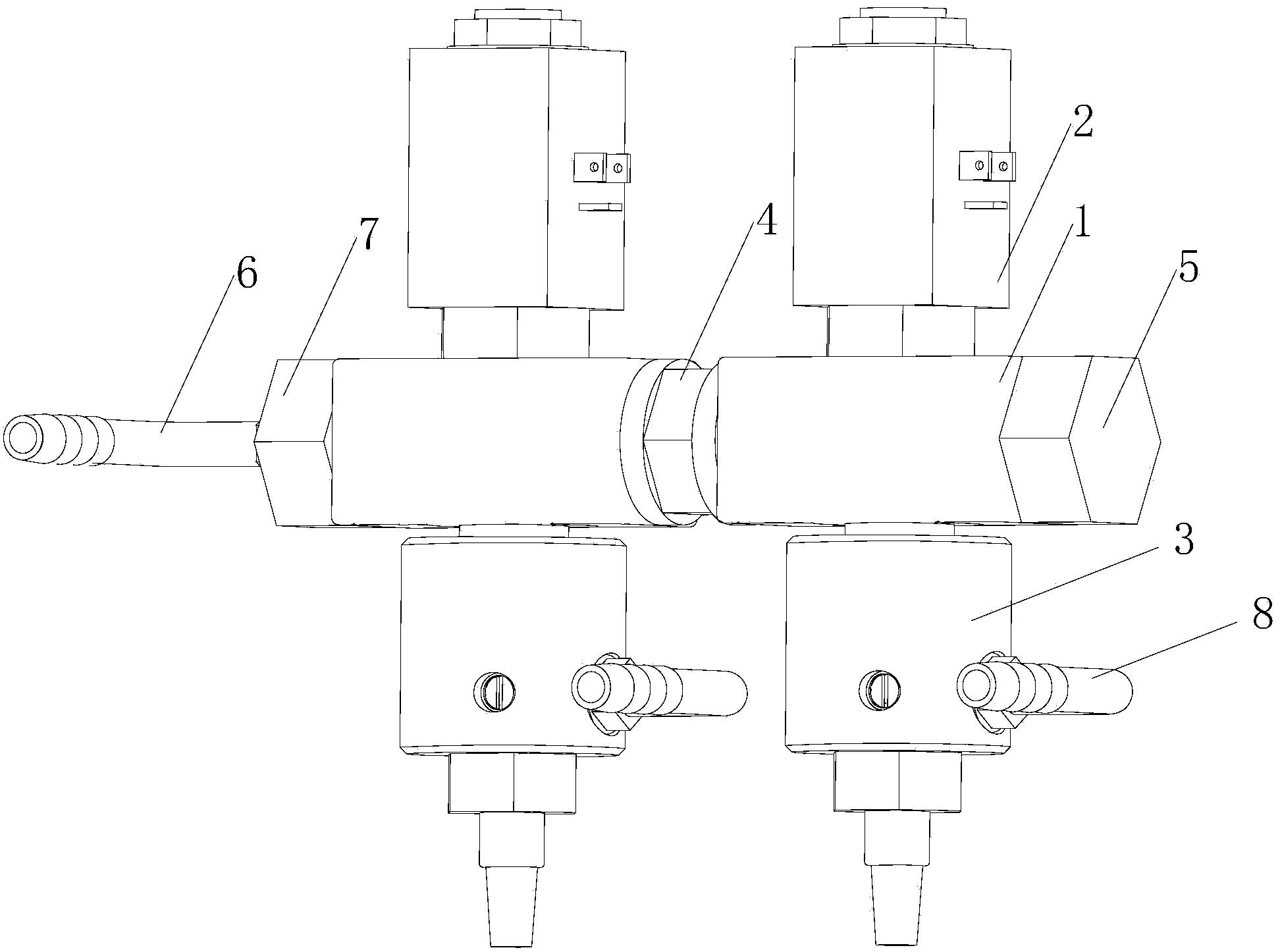

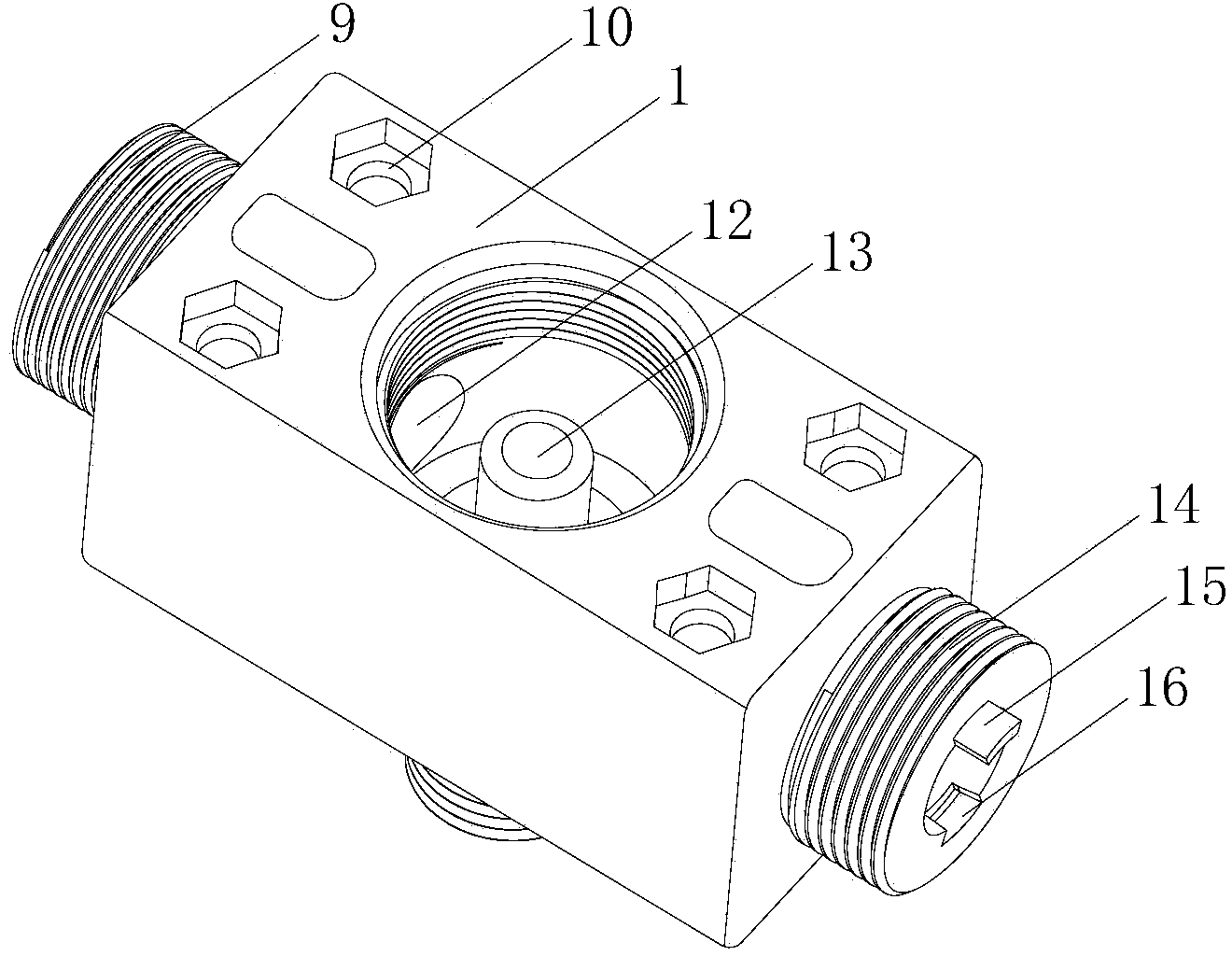

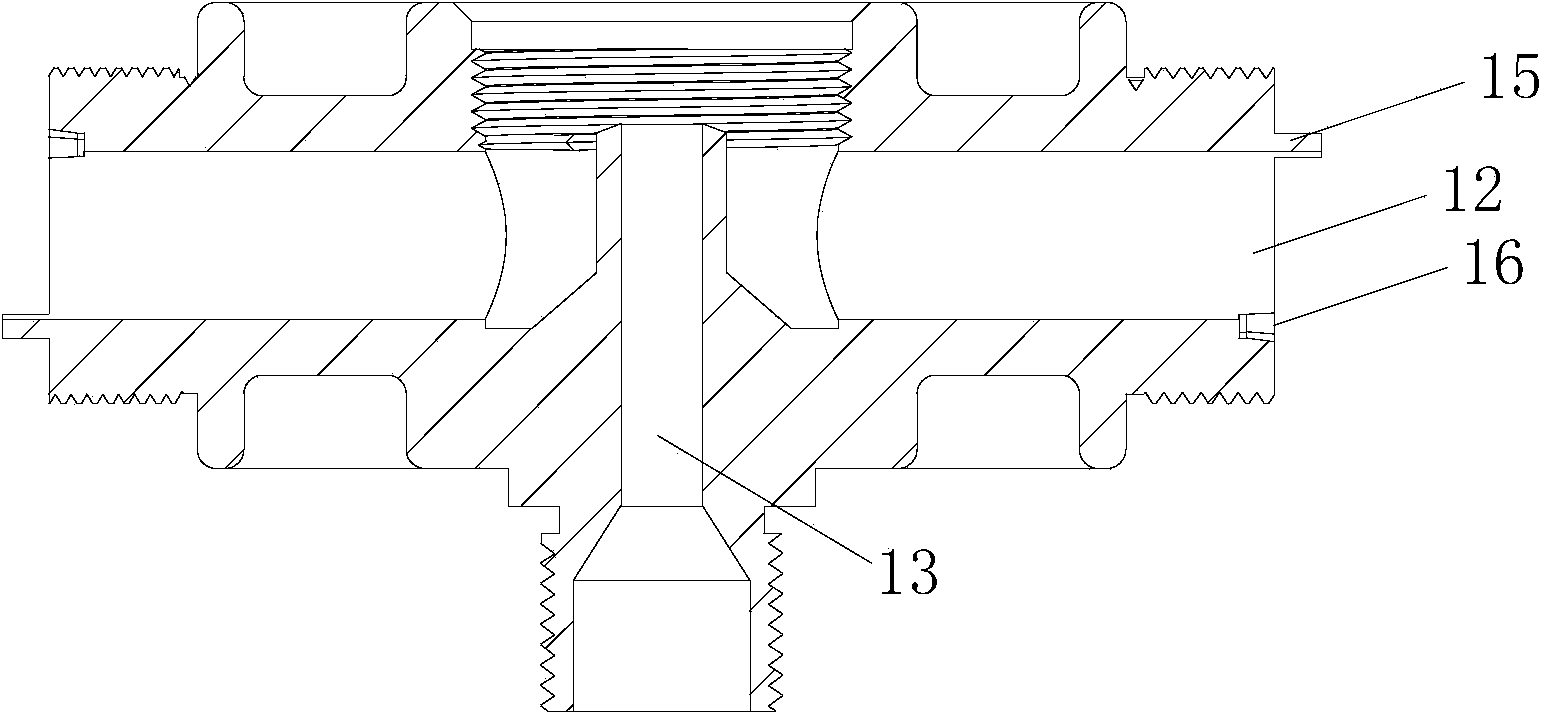

[0031] combined with Figures 1 to 7 The specific embodiment of the present invention is described further:

[0032] A ratio regulating device for liquid mixing, comprising a plurality of ratio regulating monomers with the same structure, and each ratio regulating monomer is connected in sequence. The proportional control unit includes a solenoid valve 2, a liquid inlet valve body 1, and a proportional adjustment nozzle 3. The liquid inlet valve body 1 is provided with a liquid inlet channel 12 and a liquid outlet channel 13, and the proportional adjustment nozzle 3 is connected to the outlet channel 13. end. The inlet of the liquid outlet channel 13 is located in the liquid inlet channel 12, and the inlet of the liquid outlet channel 13 is closed by the armature of the electromagnetic valve 2. The structure of the ratio regulation monomers is the same, only one set of production molds is needed, and the production cost is low; the number of ratio regulation monomers can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com