Lens for LED lamp

A technology of LED lamps and lenses, applied in the parts of lighting devices, lighting devices, light sources, etc., can solve the problems of reduced light output efficiency, reduced light energy, affecting product performance, etc., to reduce glare, large light output surface, and light output efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

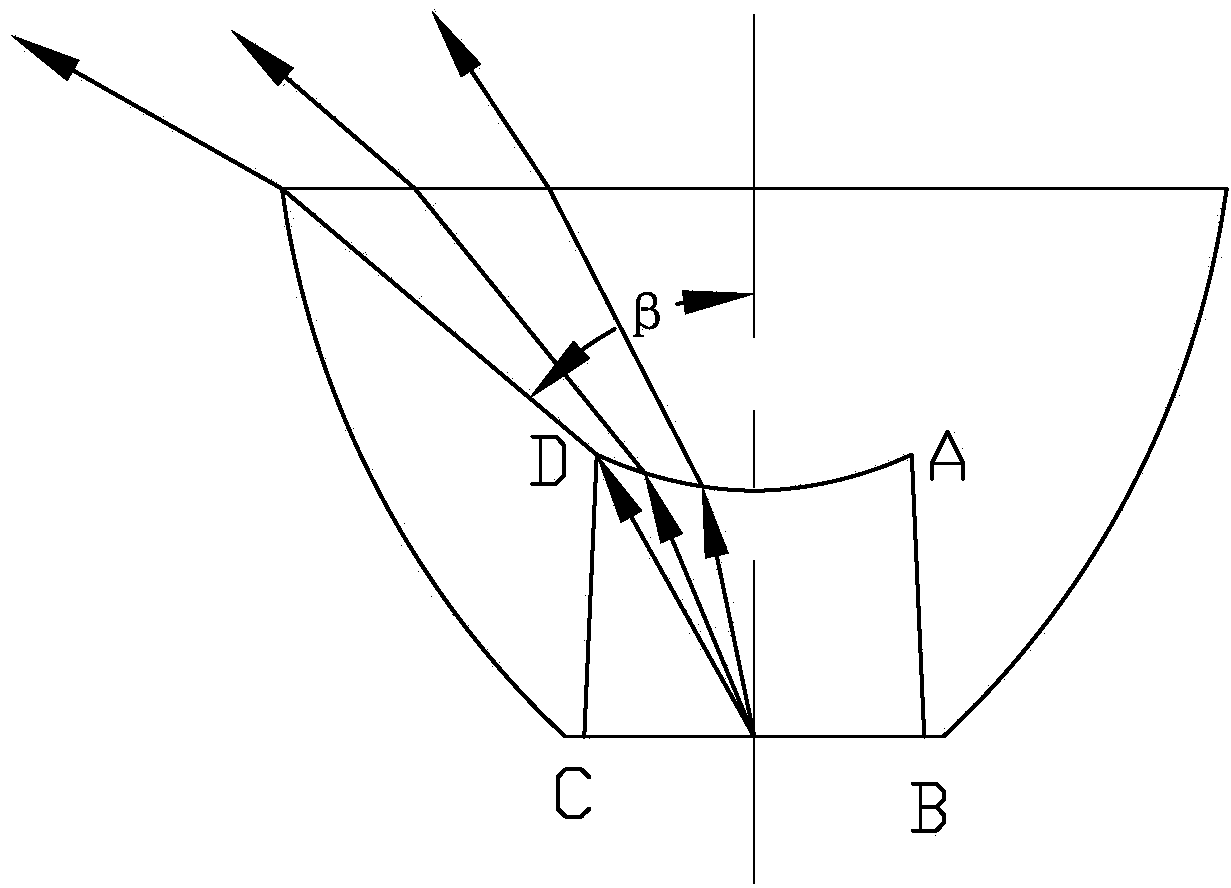

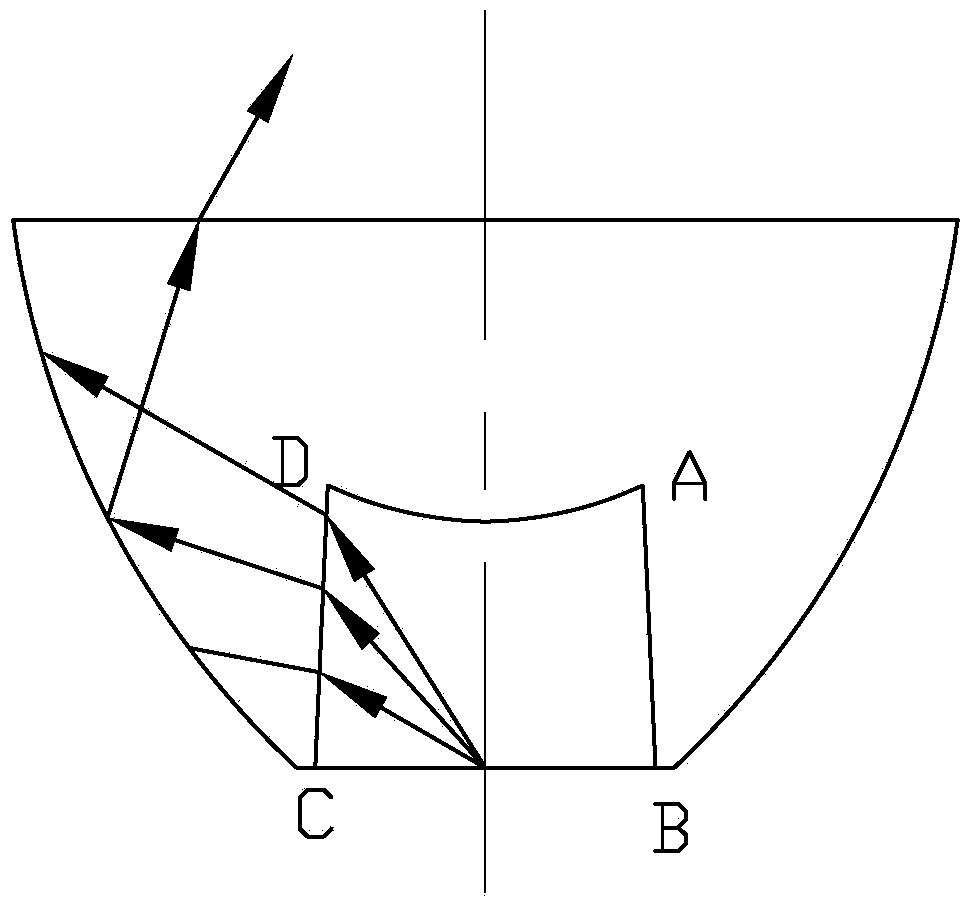

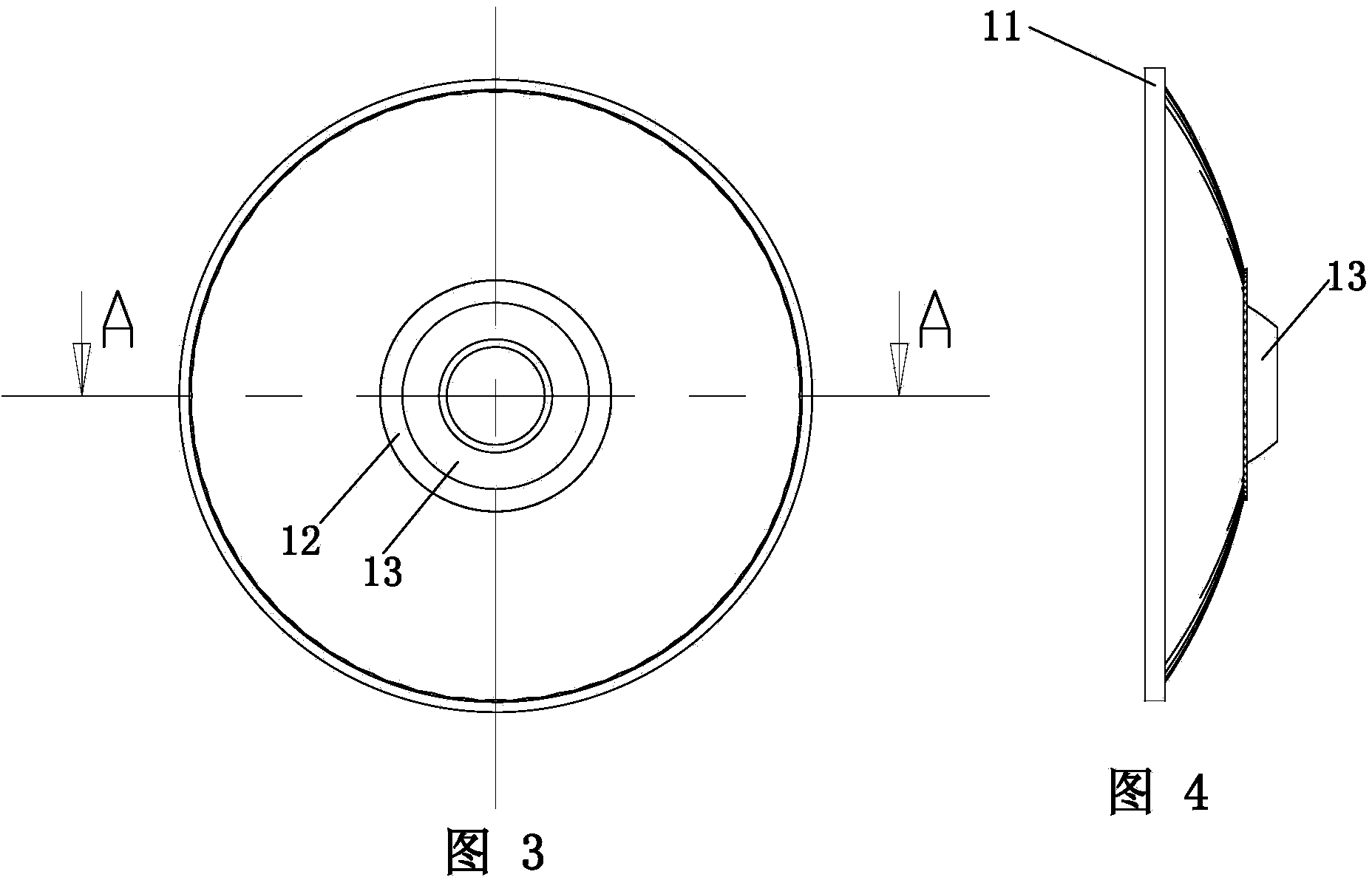

[0026] like Figure 3 to Figure 7 As shown, a lens for LED lights, the lens is basically in the shape of a truncated cone in structure, including a bottom surface with a small diameter, a top surface and a side surface with a large diameter, the top surface is a light-emitting surface, and the top surface is along the periphery of the top surface. An annular boss 11 extends outward, and a groove 12 is provided on the bottom surface of the lens. The cross section of the groove 12 is circular, and the inner diameter of the groove 12 gradually decreases from the outside to the inside. There is a protrusion 13, which protrudes from the bottom surface of the lens. The protrusion 13 is in the shape of a truncated cone as a whole. Put cavity 14, light source accommodating cavity 14 has the incident side surface that makes light enter lens, incident top surface, the shape of each part of this lens, size adopts following method to design:

[0027] Define the lens height as H1, the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com